What Is Filter Fabric?

Let’s get one thing straight—filter fabric is not sexy. It’s not going to show up in a fashion magazine or be worn on the red carpet. But when it comes to protecting your health, keeping the air clean, and saving rivers from chemical soup? Filter fabric deserves a standing ovation.

Table of Contents

Basic Definition

At its core, filter fabric is a textile material made to separate particles from fluids or air. Think of it as a sieve—but engineered with scientific precision. It’s found in air purifiers, wastewater treatment plants, vacuum cleaners, and even diapers.

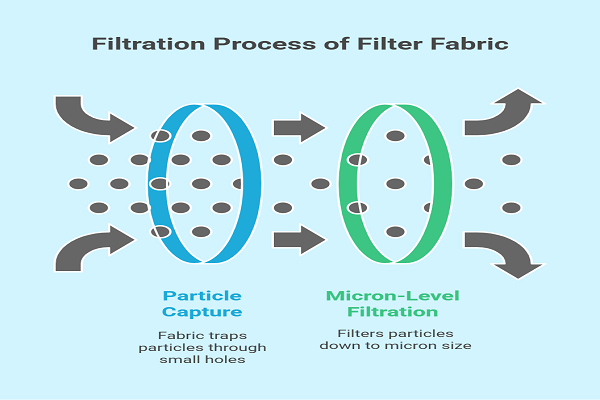

How It Works

Picture a tight net. The smaller the holes, the more gunk it catches. That’s the simple magic of filter fabric. It can trap particles down to a few microns—yes, microns. That’s 0.001 millimeters. We’re talking the size of bacteria, pollen, or even fine dust.

Types of Filter Fabric

Woven Filter Fabrics

Made by weaving yarns in a crisscross pattern. These fabrics offer mechanical strength and are mostly used in industries where structure matters, like mining and construction. They’re durable but not great for super-fine filtration.

Non-Woven Filter Fabrics

No weaving here. These are made by bonding fibers together using heat, chemicals, or pressure. They’re soft, flexible, and lightweight. Perfect for medical masks (yes, those ones you wore every day during COVID).

Needle-Punched Filter Fabrics

These involve fibers punched together by barbed needles to form a dense, felt-like material. High surface area means better filtration. Common in automotive and geotextile applications.

Applications of Filter Fabric

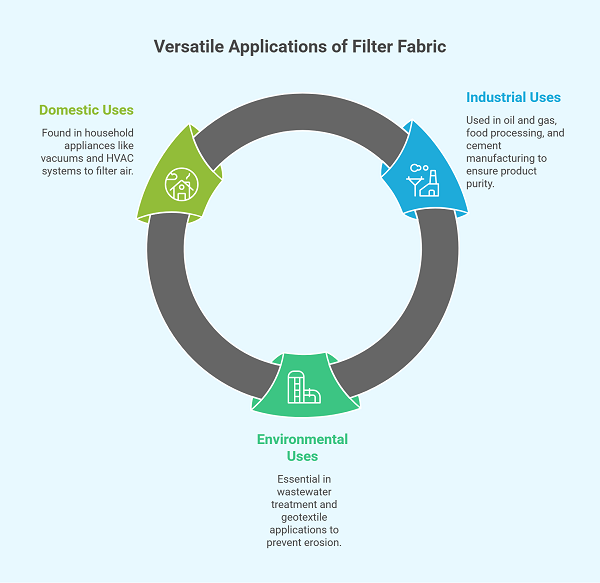

Industrial Uses

Let’s talk numbers. The global market for industrial filtration was valued at over $29 billion in 2023, and filter fabric is at the heart of it. Whether it’s oil and gas, food processing, or cement manufacturing, filter fabrics are used to trap contaminants and ensure product purity.

Environmental Uses

Here’s a fun fact: Over 80% of wastewater plants worldwide use filter fabrics to clean up sewage. Without them, raw waste would flow directly into rivers. Yikes. Geotextile filter fabrics are also used in road construction to prevent erosion and allow water drainage.

Domestic Uses

You’ve touched filter fabric today—probably in your vacuum, your HVAC system, or your washing machine. Air filters made of synthetic filter fabrics can trap 99.9% of airborne particles. That’s how your lungs are still working fine.

Technical Properties of Filter Fabric

Permeability and Flow Rate

You want water or air to pass through—just not the dirt. Filter fabrics are rated by their permeability, usually measured in liters per square meter per second (L/m²/s). The ideal rate depends on the use: high for drainage, low for precision filtering.

Filtration Efficiency

Let’s get nerdy. The filtration efficiency is often calculated using the BFE (Bacterial Filtration Efficiency) or MERV (Minimum Efficiency Reporting Value) standards. Medical-grade masks, for example, use filter fabrics with BFE over 95%.

Tensile Strength and Durability

A filter fabric should last. You don’t want it tearing under pressure—literally. Durability is measured in Newtons. A high-quality industrial filter fabric can withstand up to 400 N of force before breaking.

How to Choose the Right Filter Fabric

Application-Specific Requirements

Start by asking: what’s the job? For filtering out sand from water on a construction site, go for a heavy-duty geotextile. For cleanroom air filters, you’ll need ultra-fine non-woven fabrics with high BFE ratings.

Fabric Type Comparison

| Fabric Type | Efficiency | Strength | Cost |

| Woven | Medium | High | Medium |

| Non-Woven | High | Medium | Low |

| Needle-Punched | Very High | Very High | High |

Industry Standards and Compliance

Look for labels like ASTM D4491 (for water flow rate), or ISO 16890 (for air filters). These ensure you’re getting real performance, not just marketing fluff.

Sustainability and Filter Fabrics

Biodegradable Options

Eco-conscious? You’re not alone. Some new filter fabrics are made from PLA (polylactic acid), which is biodegradable and derived from cornstarch. Not perfect yet, but it’s a start.

Reusability and Lifecycle

Did you know that some industrial filter bags can be reused up to 50 cycles before they wear out? Washable air filters are gaining ground too. Less waste, more savings.

Conclusion

Filter fabric may not be glamorous, but it’s powerful. It keeps your lungs clean, your water drinkable, and your machines running. Whether you’re working in construction, healthcare, or just trying to breathe cleaner air at home, filter fabric is quietly doing the heavy lifting.

It’s time we gave it the credit it deserves.

FAQs

1. What is the primary purpose of filter fabric?

To trap unwanted particles while allowing air or fluid to pass through. It helps in filtration, separation, and drainage.

2. Can filter fabric be washed and reused?

Yes, especially in industrial and HVAC applications. Some filter fabrics are washable and reusable for multiple cycles.

3. What’s the difference between woven and non-woven filter fabric?

Woven fabrics are made from interlacing yarns, while non-woven ones are bonded together without weaving. Non-woven types offer finer filtration.

4. Is filter fabric eco-friendly?

Some are. PLA-based biodegradable fabrics are on the rise. Reusability also helps reduce environmental impact.

5. Where can I buy filter fabric for home projects?

Hardware stores, garden centers, or online platforms like Amazon carry rolls of filter fabric for landscaping, air filters, and DIY filtration systems.