In this article, you will get an accurate idea about the polyester manufacturing process with step by step production process.

Step By Step Polyester Manufacturing Process: Manufacturing Filament Fiber

Step-01: Polymer Formation

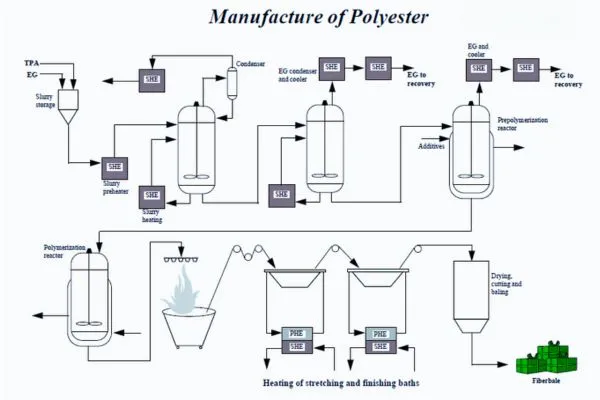

Polyester is made from ethylene, the primary constituent, by a process called polymerization. Long-chain polymer molecules of polyethylene terephthalate are created during the PET polymerization process by reacting ethylene and terephthalic acid together.

Ethylene glycol, an alcohol, and dimethyl terephthalate ester interact at a high temperature with the assistance of a catalyst. Terephthalic acid and the resultant monomer alcohol are mixed at a high temperature. The polymerized substance is extruded and air-cooled into a long ribbon shape. The ribbon is chopped into pellets once it solidifies.

Step-02: Spinning

Depending on the polyester polymer’s final applications, its polymerization level is regulated. Higher levels of polymerization are present in the polyester polymer that will be utilized in industrial fibers. Between 15,000 and 20,000 is the typical molecular weight range.

It possesses a low shear viscosity of 1000–3000 poise at the standard extrusion temperature. Ultrahigh molecular weight polyester polymer is produced by spinning at 300°C or more, while low molecular weight polyester polymer is spun at 265°C.

The winding-up rates during the spinning process are often directly related to the degree of orientation. It is theoretically possible to achieve both maximum orientation and increased production at a winding pace of 10,000 meters per minute. Adverse consequences might manifest at wind-up rates above 7000 meters per minute.

Step-03: Drawing the fiber

Polyester is supple and readily extended as much as five times its initial length as it comes out of the spinneret. The unpredictability polyester molecules are forced to line up in a parallel arrangement by the stretching. As a result, the fiber becomes more resilient, strong, and persistent. This time, the fibers don’t break as the filaments dry; instead, they solidify and become strong.

The diameter and length of drawn fibers might differ significantly based on the properties of the final product that is required. In order to make softer or duller textiles, the fibers can be additionally twisted or textured as they are being drawn.

Step-04: Winding

The filaments are prepared for winding into bobbins when the drawing process is finished. The drawn filaments must be gathered into a shape that can be handled, stored, or processed further during the winding stage, which is crucial. The winding machine ensures consistent tension and alignment by meticulously winding the filaments onto big spools or bobbins. This process is essential to preserving the filament’s quality and uniformity.

Step By Step Polyester Manufacturing Process: Manufacturing Staple Fiber

The processes of polymerization to melt-spinning are largely the same for producing polyester staple fiber as they are for making filament yarn. But when the output is stapled fiber, the spinneret has a lot more holes during the melt-spinning process. The resulting polyester bundles that resemble ropes are known as tow.

Step-01: Drawing tow

The newly produced tow is quickly cooled in specially designed cans that effectively collect the thick strands. After that, many tow lengths are mixed and meticulously stretched out on hot rollers, causing the fibers to expand to three or four times their initial length. They become stronger and more consistent in processing after this treatment.

Step-02: Crimping

After that, the pulled tow is put into the compression box, which compresses the fibers at an average of 9–15 wrinkles per inch (3-6 per centimeter), forcing them to fold like an accordion would. Later phases of production benefit from the fibers sticking together thanks to this procedure.

Mahedi Hasan working as an Executive (Fabric Marketing) at Pengnuo Group. Graduated with B.Sc. in Textile Engineering. Before was a Top Rated content writer at Upwork, and Level 02 Seller at Fiverr, Level 02 Publisher at Ezoic. Very passionate about content writing, SEO practice, and fashion website designing. Highly Experienced fashion writer for the last 4+ years. Have extensive 7 years of experience in the wholesale clothing business.