What Is a Press Button?

A press button, also called a snap button, is a fastener that joins two fabric parts using pressure instead of sewing or zipping. It’s made of two interlocking discs — one with a stud (male part) and another with a socket (female part). When pressed together, they lock firmly.

You’ll see press buttons everywhere — jeans, baby clothes, leather jackets, and even handbags. According to a 2024 market report, over 65% of global casualwear includes some form of press or snap closure. Their appeal lies in simplicity: press, click, done.

Historically, press buttons replaced traditional hooks and laces during the early 20th century, marking a small revolution in garment convenience.

Table of Contents

Types of Press Buttons

Press buttons aren’t all the same. Depending on material, structure, and purpose, several types exist.

1. Snap Press Button

This is the classic type used on shirts, jackets, and babywear. It consists of four parts: cap, socket, stud, and post. Usually made of brass or stainless steel, these are rust-resistant and long-lasting.

2. Spring Press Button

Used mainly in outerwear and bags, this version has a coiled spring inside that gives a stronger grip. It’s suitable for heavier fabrics like denim or canvas.

3. Ring Press Button

The ring-style design gives flexibility and light closure pressure. Popular for delicate fabrics and babywear, it prevents tearing or stretching around the button area.

4. Jeans Press Button

Built tough. Made from metal alloys, jeans with press buttons can handle over 80 N of pull strength. They often come with engraved logos, giving both branding and durability.

5. Magnetic Press Button

A modern twist — no pressing, just attraction. Used in luxury handbags and wallets, magnetic buttons combine function with a premium feel.

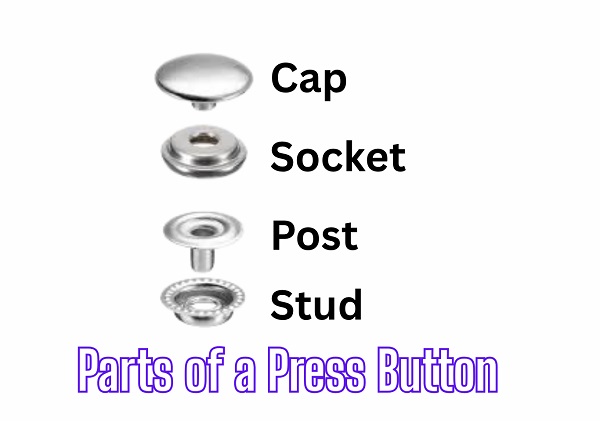

Parts of a Press Button

Every press button consists of four main components:

- Cap – visible outer part on the garment surface.

- Socket – the female part that receives the stud.

- Stud – male component that fits into the socket.

- Post–base that secures the cap to the fabric.

These parts are typically made from brass, aluminum, or stainless steel, ensuring corrosion resistance.

How to Attach a Press Button

Attaching a press button correctly is crucial for durability and safety.

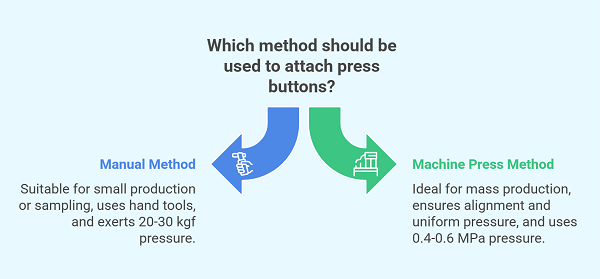

1. Manual Method Using Hand Tools

For small production or sampling, hand pliers or manual die tools are used. The process involves:

- Marking the position on the fabric

- Inserting the cap and post

- Pressing both sides firmly until locked

A simple hand press can exert 20–30 kgf of pressure, enough for most lightweight garments.

2. Machine Press Attachment Method

In mass production, pneumatic or hydraulic press machines attach buttons. These ensure alignment, uniform pressure, and reduce human error. Typical pressure range: 0.4–0.6 MPa.

3. Common Mistakes to Avoid

- Misaligned socket and stud

- Excessive pressure is causing the fabric to tear

- Loose fixing leading to detachment during washing

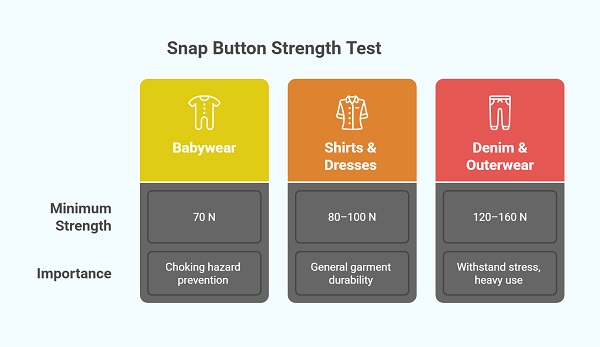

Press Button Strength Test

The snap attachment strength test checks how firmly the button is attached. This ensures it doesn’t detach during use or washing.

1. Purpose of the Test:

It helps maintain quality and safety, especially in babywear and workwear. Weak snaps can pose choking hazards.

2. Snap Attachment Strength Test Procedure

The test uses a tensile testing machine. The cap is held by one clamp, the socket by another, and a pulling force is applied.

Formula:

Snap Strength (N) = Force Required to Detach Cap from Socket

3. Equipment and Standard Procedures

- Testing Machine: Snap pull tester

- Standard: ASTM D4846, ISO 6330

- Speed: 100 mm/min

- Force Gauge Range: 0–300 N

4. Acceptable Strength Values

- Babywear: Minimum 70 N

- Shirts & Dresses: 80–100 N

- Denim & Outerwear: 120–160 N

If the value falls below the limit, the button must be reattached or replaced.

Common Problems and Quality Issues

Even a tiny press button can cause big trouble if not tested properly.

- Loose Fitting: Due to wrong die selection or pressure.

- Rust and Corrosion: Poor coating or low-grade metal.

- Fabric Damage: Caused by excessive pressing or thin material.

Applications of Press Buttons in the Garment Industry

Press buttons appear in almost every apparel category:

- Babywear: Easy closure and safety-tested snaps

- Denim Jeans: Heavy-duty metal press buttons

- Jackets & Uniforms: Spring and ring types

- Bags and Leather Goods: Magnetic press buttons for elegance

Conclusion

Press buttons may look small, but they hold the fabric world together — literally. Their evolution from basic metal snaps to modern magnetic closures shows how innovation can come from simplicity. Whether you’re designing denim, uniforms, or accessories, choosing the right press button — and testing its strength — ensures safety, durability, and comfort.

FAQs

1. What materials are press buttons made from?

Mostly brass, aluminum, stainless steel, or plastic, depending on application and strength requirement.

2. How strong should a jeans press button be?

It should withstand at least 120–160 N of pull force according to industry standards.

3. Can the press buttons be replaced easily?

Yes, with proper tools, a damaged button can be replaced without harming the fabric.

4. What is the most common cause of button failure?

Incorrect attachment pressure or using an incompatible fabric thickness.

5. Are magnetic press buttons durable?

Yes, but they are more suitable for fashion items like bags rather than heavy garments.