Pongee fabric is a medium-weight, balanced woven fabric. It is known for its balance, durability, and characteristic “slubbed” texture. Pongee fabric was traditionally made of silk in early 20th-century China, around the Yangtze River.

Today it’s commonly manufactured with polyester and poly/spandex blends. This fabric is widely used in various applications, from umbrellas to linings, due to its lightweight structure, easy maintenance, and versatile design.

Let’s know the details of pongee fabric, including its types, production, and advantages.

Table of Contents

What is Pongee Fabric?

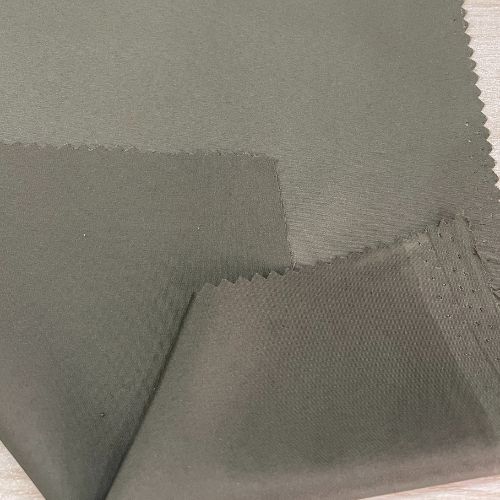

Pongee is a woven fabric with fine, balanced warp and irregular filling yarns. DTY filament yarn is used. Traditionally, was a light, naturally-colored fabric, often made of silk. Now, pongee can be made from materials like polyester, poly/spandex, and blends, providing a variety of weights and finishes.

Properties

| Properties | Details |

| Fabric Name | Pongee Fabric |

| Also Known As | Silk pongee, Polyester pongee, Poly/spandex pongee |

| Appearance | Smooth, lightweight, with slight slubbed or matte texture; silk-like sheen |

| GSM Range | 36–50 GSM |

| Composition Range | 100% Silk, 100% Polyester, Poly/Spandex blends |

| Construction Range | Plain weave with fine warp and irregular filling yarns |

| Functionality | TPU, PU, AC, W/R (Water-Resistant), PV, PVC coatings available |

| Manufacturing Process | Woven, often with slubbed yarns or textured yarn techniques |

| Thread Density Range | 190T to 480T, depending on use (lining, outerwear, umbrellas) |

| Count Variations | Commonly 50D, and 75D for polyester variants; silk pongee uses finer yarn counts |

| Full Width | 57/58” or 59/60” |

| Cuttable Width | Typically 55”–58” |

| Fabric Breathability | Moderate; varies with density and coating applied |

| Additional Coating Variations | PU, PVC, or TPU coatings for increased water resistance and UV protection |

| Moisture-Wicking Abilities | Moderate to high in polyester variants |

| Heat Retention Abilities | Low to moderate |

| Stretchability | Minimal in standard pongee; higher stretch in poly/spandex blends |

| Prone to Pilling/Bubbling | Generally low pilling; polyester versions are more resistant |

| Country of First Production | China |

| Biggest Exporting Country Today | China, followed by Japan for specialized silk pongee |

| Recommended Washing Temperatures | a. Polyester: up to 30°C, b. Silk: cold hand wash only |

| Common Applications | Umbrellas, jacket interlinings, outerwear, dresses, suits, raincoats, high-density shells for outdoor wear |

| Attribute | Details |

| Fabric Name | Pongee Fabric |

| Also Known As | Silk pongee, Polyester pongee, Poly/spandex pongee |

| Appearance | Smooth, lightweight, with slight slubbed or matte texture; silk-like sheen |

| GSM Range | 36–50 GSM |

| Composition Range | 100% Silk, 100% Polyester, Poly/Spandex blends |

| Construction Range | Plain weave with fine warp and irregular filling yarns |

| Functionality | TPU, PU, AC, W/R (Water-Resistant), PV, PVC coatings available |

| Manufacturing Process | Woven, often with slubbed yarns or textured yarn techniques |

| Thread Density Range | 190T to 480T, depending on use (lining, outerwear, umbrellas) |

| Count Variations | Commonly 50D, 75D for polyester variants; silk pongee uses finer yarn counts |

| Full Width | 57/58” or 59/60” |

| Cuttable Width | Typically 55”–58” |

| Fabric Breathability | Moderate; varies with density and coating applied |

| Additional Coating Variations | PU, PVC, or TPU coatings for increased water resistance and UV protection |

| Moisture-Wicking Abilities | Moderate to high in polyester variants |

| Heat Retention Abilities | Low to moderate |

| Stretchability | Minimal in standard pongee; higher stretch in poly/spandex blends |

| Prone to Pilling/Bubbling | Generally low pilling; polyester versions are more resistant |

| Country of First Production | China |

| Biggest Exporting Country Today | China, followed by Japan for specialized silk pongee |

| Recommended Washing Temperatures | Polyester: up to 30°C, Silk: cold hand wash only |

| Common Applications | Umbrellas, jacket linings, outerwear, dresses, suits, raincoats, high-density shells for outdoor wear |

Types of Pongee Fabric

Pongee fabric can be categorized by its elasticity and material, or by thread density (T), which measures the yarn count per square inch. Here’s an overview of the main types:

i. Elasticity-Based Types

- Semi-Elastic Pongee: 50D FDY warp and DTY weft, adds slight stretch with a slight sheen. It is used for items requiring minor elasticity without sacrificing stability.

- Full Elastic Pongee: Both warp and weft are composed of 75D, 60D, or 20D DTY, giving it full elasticity.

- Matting Pongee: Fully elastic with a coarse texture adds strength to outerwear. It offers a denser, and matte appearance. Matting pongee is preferred for applications that need more durability and weight.

ii. Material-Based Types

- Silk Pongee: Luxurious, smooth, and highly breathable, retaining traditional qualities.

- Polyester Pongee: Durable, cost-effective, and water-resistant. Ideal for outdoor use.

- Poly/Spandex Pongee: Blended with spandex for extra flexibility. Suitable for activewear.

iii. Density-Based Types (Thread Count)

- 190T Pongee: Primarily used 75D DTY filament yarn a lightweight lining fabric, often coated for UV protection.

- 210T – 240T Pongee: Commonly used in medium-grade umbrellas due to increased durability.

- 260T – 300T Pongee: Utilizes finer 50D threads, suitable for outerwear requiring a more resilient shell.

- 350T – 420T Pongee: With higher thread density, it offers a dense, smooth finish for quality rainwear.

- 450T – 480T Pongee: Extremely dense, perfect for high-end applications demanding durability and a sleek look.

Lower-density pongee fabrics like 190T and 210T serve as linings, while higher-density options are ideal for shell fabrics, providing stronger, more durable protection.

Production Process of Pongee Fabric

Pongee fabric is manufactured by weaving polyester or silk fibers in a plain weave, creating a tight, balanced structure. Here’s a step-by-step overview:

- Spinning: Pongee’s weave structure has a textured, “slubbed” effect. It is achieved by varying the twist of yarns during spinning.

- Weaving: Fine yarns, typically 50D or 75D, are tightly woven to create a smooth yet slubbed texture. Varying twist tensions during yarn spinning enhance the characteristic texture.

- Finishing: After weaving, the fabric is treated with water-resistant or UV-resistant coatings. Which enhances durability and functionality. For instance, pongee used in umbrellas may receive black or silver TPU coatings for extra UV protection.

Applications of Pongee Fabric

The lightweight, durable nature of pongee fabric makes it ideal for a range of applications:

- Umbrellas: Commonly used in high-quality umbrellas. Especially 210T and 240T pongee, as it’s water-resistant, lightweight, and easily foldable.

- Apparel Linings: Pongee’s smooth texture and breathability make it popular for lining jackets, blouses, suits, and coats.

- Outerwear Shells: Higher-density pongee is suitable for shell fabrics in rain jackets, providing water resistance and flexibility.

- Home Textiles: Also found in drapes and cushion covers due to its low maintenance and aesthetic qualities.

Advantages of Pongee Over Nylon

Pongee fabric offers unique advantages compared to nylon, especially for outerwear applications:

- Better Water Resistance: Pongee has a naturally tighter weave that resists water more effectively than most nylons.

- Enhanced Breathability: It offers improved ventilation, making it more comfortable for apparel.

- More Natural Texture: Pongee mimics silk, providing a smoother, softer feel compared to nylon’s synthetic texture.

- Wrinkle Resistance: Pongee holds its shape better, with fewer wrinkles compared to nylon.

- UV Protection: Higher-density pongee (190T or above) often has coatings that provide additional UV protection, ideal for outdoor use.

Conclusion

Pongee fabric has grown from its roots in Chinese silk to become a versatile, widely used textile in both fashion and outdoor industries. With options ranging from polyester to silk and elastic blends, pongee meets a variety of needs while providing benefits like water resistance, UV protection, and a soft texture. Whether in umbrellas, apparel, or home textiles, pongee remains a go-to fabric due to its practical properties and reliable performance.

Mahedi Hasan working as an Executive (Fabric Marketing) at Pengnuo Group. Graduated with B.Sc. in Textile Engineering. Before was a Top Rated content writer at Upwork, and Level 02 Seller at Fiverr, Level 02 Publisher at Ezoic. Very passionate about content writing, SEO practice, and fashion website designing. Highly Experienced fashion writer for the last 4+ years. Have extensive 7 years of experience in the wholesale clothing business.