Washing and dyeing machinery has come a long way from the early days of manual labor-intensive processes. In today’s dynamic industrial landscape, these machines play a pivotal role in ensuring efficiency, quality, and sustainability. Let’s delve into the features that make modern washing and dyeing machinery indispensable.

Table of Contents

Features Of Washing Machine

- PLC and touch screen, programmable system.

- Equip one more motor, and can move the garment bracket left and right.

- Water lever sensor * 3, can inject water and stop automatically.

- Digital depth sensors can be programmed and dyed different depths automatically, by setting depth and time.

- Semi-automatic feeding tank, inject chemicals according to time setting.

- Full-automatic dosing tank, inject chemicals according to time and volume setting.

Modern Washing Machines Features

- Energy Efficiency and Eco-Friendly Options: Modern washing machines prioritize energy efficiency, offering eco-friendly alternatives that align with contemporary environmental concerns. Innovations like low-water washing and quick cycles contribute to reduced energy consumption.

- Advanced Washing Technologies: The incorporation of steam cleaning and ultrasonic cleaning technologies sets modern washing machines apart. These advancements not only enhance cleaning effectiveness but also cater to specific fabric needs, ensuring a gentle yet thorough wash

Dyeing Machine

The garment dyeing machine is designed for modern apparel dyeing. windily used in woolen sweaters, acrylic and cotton jerseys bleaching, boiling and washing, gloves, socks, and towels’ dyeing.

Main Features Of Dyeing Machine:

The dyeing industry has witnessed a revolution with the advent of machinery. Contemporary dyeing processes involve precision-controlled applications, ensuring vibrant and consistent coloration across various materials. The feature of the garment dyeing machine is as:

- Made of excellent and corrosion-resistant stainless steel, it is sturdy and durable.

- Equip direct/ indirect heating system.

- Digital control panel with small dyeing computer.

- The paddles stir dyeing liquor automatically so that the garment’s color is uniform and perfect.

- Pneumatic draining pneumatic heating (direct/indirect).

Optional Automatic Function:

- PLC and touch screen, programmable system.

- Water flow meter, can inject water and stop automatically.

- Can equip inverter, control paddles rotate speed automatically.

- Semi-automatic feeding tank, inject chemicals according to time setting.

- Full-automatic dosing tank, inject chemicals according to time and volume setting.

| Models | CY-2-5-8 | CY-20 | CY-50 | CY-100 | CY-200 | CY-300 | CY-400 | CY-600 | CY-800 | |

| Capacity | lbs | 15 | 20 | 50 | 100 | 200 | 300 | 400 | 600 | 800 |

| Paddle spin speed | rpm | 20 | 20 | 20 | 20 | 20 | 20 | 25 | 25 | 25 |

| Steam connection | θ | DN20 | DN20 | DN25 | DN25 | DN25 | DN25 | DN25 | DN25 | DN25 |

| Water connection | θ | DN20 | DN20 | DN20 | DN20 | DN20 | DN80 | DN80 | DN80 | DN80 |

| Steam max pressure | Bar | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 |

| Water max pressure | Bar | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Air max pressure | Bar | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Power of motor | KW | 0.55 | 0.55 | 0.75 | 1.5 | 2.2 | 2.2 | 3 | 3 | 5.5 |

| Voltage | Volt/Hz | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 |

| Machine length | mm | 1380 | 1120 | 1630 | 2000 | 2620 | 2920 | 3290 | 3830 | 4550 |

| Machine width | mm | 1100 | 1040 | 1200 | 1520 | 1830 | 1980 | 2080 | 2200 | 2470 |

| Machine height | mm | 1100 | 1270 | 1370 | 1600 | 1880 | 1940 | 2180 | 2210 | 2510 |

| Machine weight | kg | 140 | 155 | 290 | 450 | 730 | 980 | 1350 | 1700 | 1800 |

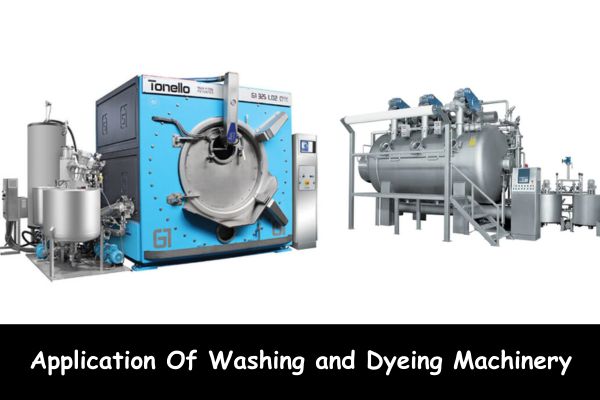

Application Of Washing and Dyeing Machinery

1. Increased Efficiency in Large-Scale Production

Industries, particularly textiles and manufacturing, benefit from the efficiency of modern washing and dyeing machinery. Large-scale production demands machines that can handle volume without compromising on quality, a feat these machines achieve effortlessly.

2. Cost-Effectiveness and Reduced Environmental Impact

In the pursuit of sustainable practices, modern machinery offers cost-effective solutions that also minimize the environmental footprint. Reduced water and chemical usage contribute to both economic and ecological advantages.

3. Handling Various Fabric Types

One of the notable features of these machines is their ability to handle a diverse range of fabrics and materials. Whether it’s delicate silk or heavy-duty denim, modern washing and dyeing machinery offer tailored solutions for different textile requirements.

4. Customization Options

Customization is key in the textile industry. Modern machinery provides customization options, allowing industries to achieve unique dyeing effects and patterns, meeting the demands of ever-changing fashion trends.

5. Quality Control Measures

Maintaining consistent quality is paramount in industrial processes. Washing and dyeing machinery incorporate rigorous quality control measures, ensuring that each batch meets predefined standards, thus reducing waste and rework.

6. Consistent and High-Quality Results

From color accuracy to fabric integrity, these machines deliver results that are not only consistent but also of superior quality. The integration of advanced sensors and monitoring systems guarantees precision throughout the process.

Are modern washing machines more energy-efficient than traditional ones?

Yes, modern washing machines prioritize energy efficiency through innovations like low-water washing and quick cycles.

How do washing and dyeing machinery contribute to sustainability?

These machines reduce environmental impact by minimizing water and chemical usage, aligning with sustainable practices.

Can modern machinery handle different types of fabrics?

Modern washing and dyeing machinery are designed to handle a diverse range of fabrics, offering customization options for various textile needs.

What challenges are commonly faced in using washing and dyeing machinery?

Challenges include initial costs, technical complexities, and training requirements, but innovative solutions are continually being developed.

What are the anticipated future trends in washing and dyeing machinery?

Emerging technologies such as AI and IoT integration are expected to shape the future, enhancing efficiency and precision in industrial processes.

Conclusion

In conclusion, the features of washing and dyeing machinery have redefined industrial processes across various sectors. From efficiency and customization to sustainability and quality control, these machines embody the pinnacle of technological advancement. As industries continue to evolve, the role of modern washing and dyeing machinery remains integral to their success.

Mahedi Hasan working as an Executive (Fabric Marketing) at Pengnuo Group. Graduated with B.Sc. in Textile Engineering. Before was a Top Rated content writer at Upwork, and Level 02 Seller at Fiverr, Level 02 Publisher at Ezoic. Very passionate about content writing, SEO practice, and fashion website designing. Highly Experienced fashion writer for the last 4+ years. Have extensive 7 years of experience in the wholesale clothing business.