In today’s covid pandemic situation all over the world, the medical-grade meltblown fabric proved as a blessing for the world. Meltblown Fabric is a unique medical-grade textile material. It is the raw materials of most of the medical equipment including medical gown, PPE, mask, and other medical personal protective equipment. Let’s talk about medical grade meltblown fabric.

What is Meltblown Fabric?

Meloblown is a non-woven fabric made from a conventional manufacturing process called Melt blowing. The melt blowning process is a unique fabrication method of micro-and nanofibers. Where polymer melt is cast down through tiny nozzles surrounded by high-speed blowing gas or vapor. In this one-step process, high-velocity air blows on a molten thermoplastic resin from an extruder die tip onto a conveyor otherwise on a take-up screen to form a thick fibrous and self-bonding web structure.

Melt Brown Fabric Manufacturing Process:

FIg: Step by Step MeltBrown Manufacturing Process[/caption]

FIg: Step by Step MeltBrown Manufacturing Process[/caption]Multifunctional meltblown polymer composite is manufactured by using melt-blowing technology from 88 wt.% polypropylene with 12 wt.% Eethylene terephthalates and other functional modifiers.

Properties of MeltBlown Fabric:

| Fabric Name | Medical Grade Meltblown Fabric |

| Structure: | Finer or ultra-fine fiber and fabric, as well as bigger total surface area. |

| Fabric Strength: | Lower |

| Durability: | Lower |

| Popular width: | 17.5 to 18cm. |

| Filtration: | High filtration efficiency |

| Inhalation Risk: | Higher |

| Resistance: | Low |

| Porosity: | High porosity and small pore size. |

| Chemical stability: | Good chemical stability. |

| Temperature usage: | wide temperature usage. |

| Retardancy: | Flame retardant, make the barrier to bacteria. |

| Absorbency: | Oil and liquid adsorbents. |

| Washability (Melting Point): | Lower |

| User Comfortability: | Super comfortable, soft feel good, can be directly in contact with the skin. |

Meltblown Fabric Applications:

- Surgical Gowns,

- medical mask material,

- Dustproof masks material,

- Surgical Drapes,

- Air filtration material,

- Bandages,

- Sponges,

- Various Types of Respiration Material,

- Calendered wipe and oil absorbent material,

- Instrument Wraps,

- Baby Diapers,

- Sanitary Pad material,

- Adult Incontinence, and so on.

Medical Grade Meltblown Fabric

In Melt blown manufacturing process, 100% polypropylene medical-grade nonwovens are produced. Today, it’s an important component in the manufacture of PEE, face masks, and the staff like this. From the application, we can easily assume how much medical fabric has been integrated to manufacture protective materials.

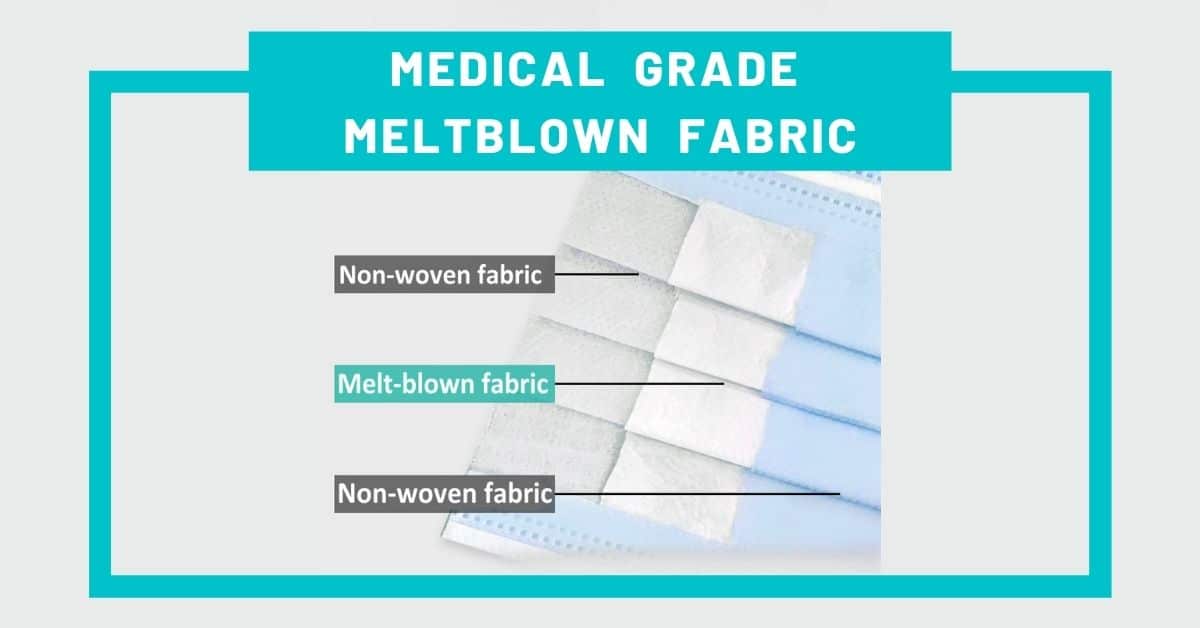

Medial grade Meltblown has a dense microfiber structure, that acts as a supper barrier against particles and other hazardous contaminating agents, as well as it’s combining high filtration efficiency with excellent air permeability. It could be combined with one or more spun bond layers to provide necessary abrasion resistance and strength.

Consequently, Melt-blown fabric made filter fabric becomes a key part of medical respirators that can provide the majority of the medical textile protection. It is widely used in disposable respirators, as well as in surgical respirators. Disposable face mask, surgical mask, surgical gown, personal protective equipment, patient clothes, operation cover, operation cap, shoe cover, sheet, etc on the list.

In Sanitary and health products such as feminine hygiene materials, baby diaper, hygiene pad, adult diaper, and so on. Sometimes melt brown material has to use the cover of the high absorbent material after hydrophilic treatment. Examples as diaper edge for preventing leaking, and diaper backing after composite with other material.

Today, melt-blowing technology use polypropylene (88 wt.%), polyethene terephthalate (12 wt.%) with some addition of functional modifiers to manufacture multifunctional polymer composite materials. Therefore, a melt-blown technique for manufacturing nonwoven products has been forecast in the last few years. It is the fastest-growing in the nonwoven industry.

This world’s covid- 19 pandemic situation is boosting up this Meltblown technology. With the current statistics, we can assume that it’s way to becoming one of the major nonwoven technologies. It would make a strong and bright future for the medical sector as well as the nonwoven textile industry.

Mahedi Hasan working as an Executive (Fabric Marketing) at Pengnuo Group. Graduated with B.Sc. in Textile Engineering. Before was a Top Rated content writer at Upwork, and Level 02 Seller at Fiverr, Level 02 Publisher at Ezoic. Very passionate about content writing, SEO practice, and fashion website designing. Highly Experienced fashion writer for the last 4+ years. Have extensive 7 years of experience in the wholesale clothing business.