In 2022, private-owned industries in the United States reported a total of 2.8 million nonfatal workplace injuries and ailments. The textile sector was a significant contributor, due to the inherent risks associated with the job. From machinery mishaps to chemical exposures, the textile industry can be hazardous for workers without strict safety measures.

Let’s dive into how personal injuries can occur in this industry. You should also focus on why safety standards are crucial to protecting those who work in it.

Table of Contents

Textile Manufacturing Personal Injuries

Machinery-Related Injuries

The textile manufacturing industry is heavily reliant on machines designed for specific tasks such as spinning, weaving, cutting, and stitching. These devices put workers at serious risk even though they are necessary for efficient production. The speed of the machinery can lead to severe injuries if proper safety measures are not in place.

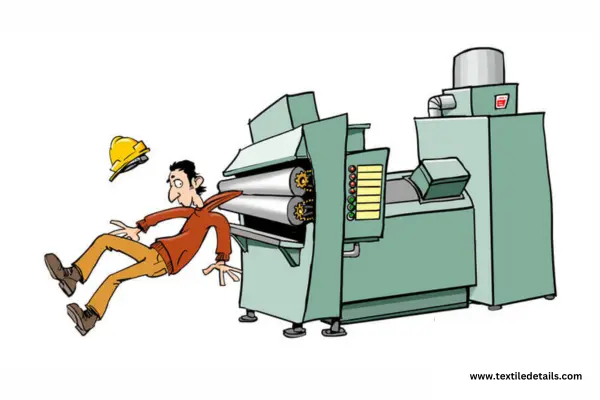

Machine Entanglement

Entanglement hazards occur when workers’ clothing or hair gets caught in machinery, leading to severe injuries. In early 2024, a young South Carolina textile worker was killed after getting trapped inside a machine she was operating.

This emphasizes the necessity of stringent safety procedures and routine upkeep. In cases like these that lead to the deaths of personnel, liable parties could face charges for wrongful death, according to TorHoerman Law.

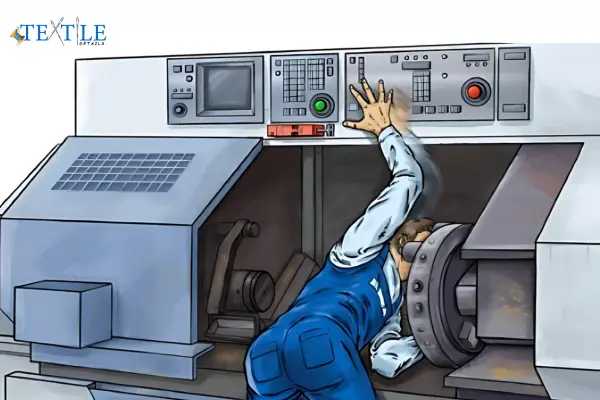

Crushing Injuries

Crushing injuries are another risk. Here, heavy machinery can crush body parts if safety guards are absent or procedures are not followed.

In 2022, the U.S. Bureau of Labor Statistics reported 2.3 million workplace injuries, with machinery-related incidents being significant. Especially in the textile industry, such cases are evident due to the improper handling of machinery.

Cuts and Lacerations

These injuries are commonplace in textile manufacturing, where sharp tools are used frequently. Without proper work approaches, workers can sustain deep cuts. Sartex Quilts and Textiles Limited was recently fined over £250,000 after two employees sustained serious hand and finger-cut injuries.

Chemical Hazards

These hazards in the textile industry are a concern due to the heavy chemical use in dyeing and finishing fabrics. The practice poses major health threats to workers. Skin irritation and burns are common. Many chemicals cause severe irritation or burns upon contact, often leading to morbidity among textile workers. Common allergens are textile finishes, textile dyes, detergents, rubber allergens, and toxic solvents.

Respiratory problems are also a major risk. Inhaling chemical fumes can lead to asthma and other chronic conditions. The U.S. Bureau of Labor Statistics reported a 35.4% increase in respiratory illness cases in 2022. The insights highlight the growing concern over workplace chemical exposures.

Extended exposure to specific chemicals may lead to cancer and reproductive disorders. According to Johns Hopkins Medicine, directly inhaling dust from natural fibers over a prolonged period leads to Brown Lung Disease.

The Importance of Safety Standards and Regulations

Adhering to Occupational Safety and Health Administration (OSHA) guidelines can help mitigate risks. The approach can ensure a safer working environment for all textile workers. Recently, there have been significant developments in an OSHA-related case where a St. Louis contractor faced substantial fines. Specifically, the contractor was fined $258,000 for exposing workers to potentially deadly hazards.

This case was significant due to the repeated OSHA violations over a short period. Moreover, it highlights ongoing safety concerns and enforcement actions by OSHA in the region. St. Louis personal injury lawyers closely monitor such cases. They reflect the critical need for rigorous enforcement of safety standards to protect workers’ rights and well-being.

Given the numerous risks in textile manufacturing, the importance of safety standards and regulations cannot be overstated:

- Preventing injuries: Using machine guards, protective gear, and regular maintenance reduces accidents. In the textile segment, safeguarding machinery and training workers cut injury rates.

- Mitigating health hazards: Proper chemical handling, storage, labeling, PPE, ventilation, and health check-ups prevent long-term issues from hazardous substances.

- Legal and financial benefits: Following OSHA standards avoids penalties and lowers financial burdens. Prioritizing safety reduces worker’s compensation costs and boosts morale.

Frequently Asked Questions

Which are the most common injuries in textile manufacturing?

Common injuries include entanglement, crushing, and cuts due to fast-moving machinery and sharp tools. Tasks that involve continuous bending, lifting, and stretching lead to muscle strains, and repetitive strain injuries like carpal tunnel syndrome. Inhalation of fibers can also cause respiratory issues.

What financial and legal ramifications result from workplace injuries?

Workplace injuries can result in significant legal penalties and increased financial costs. Financially, companies may face huge insurance premiums, legal fees, and expenses linked with workers’ compensation claims. Companies must comply with workplace safety regulations to avoid fines and other penalties.

How does proper training help in reducing workplace injuries?

Workers who receive the proper training are guaranteed to understand safety protocols and be able to operate machinery safely. Businesses benefit from a better safety reputation and improved employee morale and productivity. Moreover, well-informed workers are likely to be more efficient and engaged.

What role does protective equipment play in textile manufacturing safety?

Protective equipment, like gloves and masks, shields workers from chemical exposure. The use of specialized textiles in PPE, like high-performance fibers and multi-functional materials, provides protection against mechanical, and thermal hazards. These protective textiles are designed to be durable and resistant to varied damages.

To wrap up, textile manufacturing is an industry fraught with potential dangers. Yet with the right safety standards and regulations, these risks can be significantly reduced. Protecting the workers who produce our textiles should be a top priority, safeguarded against the hazards they face every day.

Monjurul Hasan, An On-Page SEO Expert on WordPress. Study in Automobile & Textile Engineering at Bangladesh Sweden Polytechnic Institute (BSPI). Having 3+ years of experience in Automobile and Technical Textile Products. Working at Upwork & Fiverr MarketPlace . Highly interested in technical product development and fashion forecasting.