Textile fibers are the fundamental building blocks of textiles. The classification of textile fiber plays a crucial role in determining the characteristics and quality of the final textile product.

In this article, we look into the world of textile fiber classification, exploring both natural and synthetic fibers, as well as their properties, testing methods, and future trends.

Table of Contents

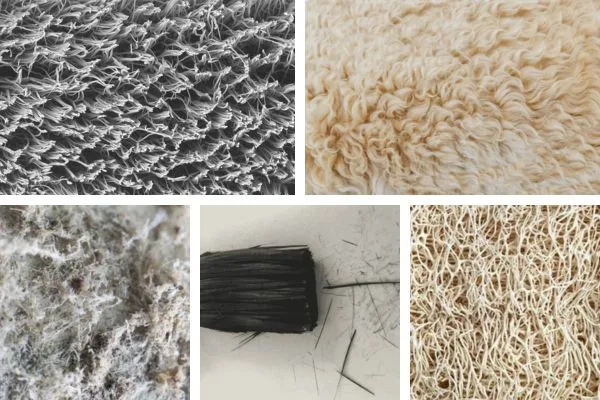

Types of Textile Fiber

Textile fibers are defined as materials that can be spun into yarns and made into fabrics or textiles. These fibers can be natural, synthetic, or regenerated, each possessing unique properties and applications. The classification of textile fibers serves as a framework for understanding their origins, characteristics, and uses.

Learn More: Definition of Textile Fiber

1. Natural Fiber:

A fiber occurring in nature is called natural fiber; for example, cotton, or silk.

Natural fibers are formed from plants, animals, or minerals. They have been used for thousands of years to create textiles and are prized for their comfort, breathability, and sustainability.

- Vegetable Fiber: Bast (jute, Flax), Leaf (Sisal, Alpacas, Pineapple) Seed (Cotton, Kapok).

Vegetable fiber or Plant-based fibers are obtained from various parts of plants, including seeds, stems, leaves, and fruits. These fibers are known for their softness, absorbency, and versatility.

- Animal Fiber: Wool & Hair

Animal-based fibers are sourced from animal sources such as wool, silk, and cashmere. Wool is obtained from the fleece of sheep. It is valued for its warmth, elasticity, and moisture-wicking properties. Silk is produced by silkworms. It is well known for its luxurious feel and natural sheen.

- Mineral Fiber: (Asbestos)

Mineral-based fibers, although less common, include asbestos and glass fibers. Asbestos was once widely used in construction and textiles. It is now banned in many countries due to its carcinogenic properties. Glass fibers, on the other hand, are used in applications requiring high strength and heat resistance.

2. Man Made Fiber

A fiber that does not occur in nature is called man-mad fiber; for example, Nylon, Polyester, and Rayon.

Synthetic fibers are man-made materials created through chemical processes. They are designed to mimic the properties of natural fibers while offering additional benefits such as durability, wrinkle resistance, and colorfastness.

1. Natural Fiber: Cellulose (Rayon), Cellulose esters, Protein, Miscellaneous.

2. Synthetic Fiber: Polyamides, Polyesters, Polyvinyl, Polyolefin, Polyurethanes, Miscellaneous.

Regenerated fibers are produced by dissolving natural materials such as cellulose and then reconstituting them into fiber form. Examples include rayon, modal, and lyocell. These fibers combine the best qualities of natural and synthetic fibers, offering comfort, breathability, and eco-friendliness.

Fiber Classification by End Use

Textile fibers can also be classified based on their intended end use, whether in apparel, home furnishings, or industrial applications. Apparel fibers, such as cotton and polyester, are designed for clothing and accessories, while industrial fibers, such as aramid and carbon, are used in specialized applications like aerospace and automotive industries.

Characteristics of Textile Fiber:

- Fibrous structure

- Color

- Fineness

- Length

- Spun able

- Elasticity & Flexibility

- Sufficient Strength

- Dye ability

- Cohesiveness

Difference Between Natural Fiber and Man-made Fiber:

| Natural fiber | Man-made fiber |

| i) Occur in nature. | i) Don’t occur in nature. |

| ii) No. of molecules is not limited. | ii) No. of molecules is limited. |

| iii) No. of molecules controlled by nature. | iii) No. of molecules controlled by man. |

| iv) Less durable. | iv) More durable. |

| v) Expensive. | v) Not expensive. |

| vi) Hygienic. | Vi) Not hygienic |

| vii) Comfortable and good for health. | vii) Uncomfortable and not good for health. |

| viii) Cannot grow everywhere. | viii) Can grow everywhere. |

| ix) Example: Cotton, Jute, silk. | ix) Example: Nylon, polyester, rayon. |

Other Classification of Fiber

Regenerated fiber: A fiber formed from a solution of a natural polymer and having the same chemical constitution as the natural polymer from which the solution was made is called regenerated fiber. Example: Rayon, Acetate

Synesthetic fiber: The fiber that is obtained by chemical synthesis is called synthetic fiber. Example: Nylon, Polyester.

Filament fiber: A fiber of indefinite length is called filament fiber. Example: silk.

Staple fiber: A fiber of definite length is called staple fiber. Example: Cotton, Wool.

Microfiber: The fiber that is as fine as 1 denier or less than 1 denier is called microfiber. Example: Nylon, Nomex.

Nanofiber: The fiber that is as fine as one to a hundred nanometers is called Nanofiber.

Animal fiber: Animal fibers are natural fibers that consist largely of particular proteins. For example: Wool and silk.

Mineral fiber: The fibers that are formed by spinning or drawing molten minerals are called mineral fibers. Example: Asbestos, Graphite.

Crystallinity: The orderly, parallel arrangement of polymer molecules within a fiber is called crystallinity.

Amorphousness: The random or unorganized arrangement of polymer molecules within a fiber is called amorphousness.

Difference Between Properties of More Crystalline and More Amorphous Fiber:

| Properties of more crystalline fiber | Properties of more amorphous fiber |

| i) Stronger | i) Weaker |

| ii) More durable | ii) Less durable |

| iii) Less absorbent | iii) More absorbent |

| iv) Less pliable | iv) More pliable |

| v) Less plastic | v) Plastic |

| vi) Less easily dyed | vi) More easily dyed |

| vii) Less degrade by chemicals | vii) More degrade by chemicals |

Conclusion

In conclusion, the classification of textile fibers is a complex yet essential aspect of the textile industry. By understanding the origins, properties, and applications of different types of fibers, manufacturers and consumers can.