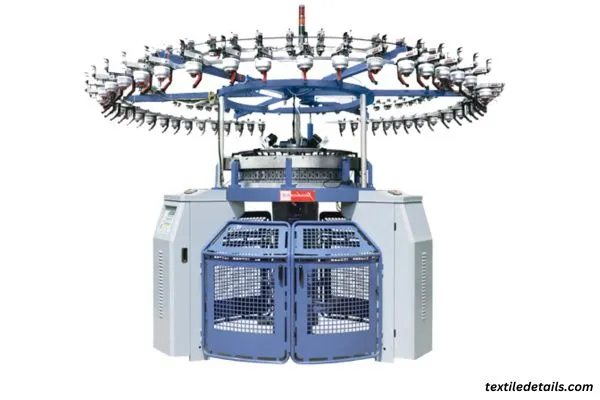

In the modern world of textile manufacturing, Single Jersey Circular Knitting Machines are a fundamental tool in the textile industry. Single Jersey Circular Knitting M/C, often referred to as S/J M/C, has witnessed significant advancements in recent years, revolutionizing the way we produce high-quality fabrics. These machines produce single-faced fabrics, characterized by a smooth surface on one side and loops on the other. In this article, we’ll show the features of a Single Jersey Circular Knitting Machine with modern single jersey machine.

Features of Single Jersey Circular Knitting Machine

- Only a cylinder is used.

- One set of needles is used.

- Max machine gauge 24/ 60 upto in modern S/J machine.

- The cylinder has cams-rising & stitch cam.

- Sinker is used / but the dial is not used.

- Vertical needle position.

- Up to 120 feeders are available.

- Machine capacity is high.

- Machine dia of 26”-30”.

- Fiber cut up to 28 is available.

Features of Modern Circular Knitting Machine

- It has a cylindrical needle bed.

- Consists of 3 major sections (yarn supply, knitting element & fabric take down).

- All three types of needles can be used.

- Sinkers and dial for dial are used.

- Needle needle-retaining spring is present.

- Yarn supply from cores situated on overhead bobbins.

- Up to 60 machine gauges are available.

- The positive feed provides 3 different speeds.

- Automatic lubrication system.

Difference between Single Jersey circular knitting machine with Modern single-jersey circular knitting

Here’s a table comparing the “Single Jersey Circular Knitting Machine” with “Modern Single Jersey Circular Knitting”:

| Feature | Single Jersey Circular Knitting Machine | Modern Single Jersey Circular Knitting |

|---|---|---|

| Knitting Technology | Traditional circular knitting technology with a single set of needles | Incorporates advanced knitting technology, often with computerized controls and multiple needle sets for enhanced efficiency and flexibility |

| Productivity | May have lower production speeds compared to modern machines | Generally offers higher production speeds, leading to increased output and efficiency |

| Needle Arrangement | Typically has a single needle set arranged in a cylinder or dial | Features advanced needle arrangements for intricate stitch patterns and varied fabric structures |

| Versatility | Limited versatility in terms of stitch patterns and fabric types | Offers greater versatility, allowing for a wide range of stitch patterns and fabric constructions |

| Control System | Manual or basic controls for stitch settings | Equipped with modern, computerized control systems for precise stitch control and pattern variations |

| Ease of Operation | May require more manual intervention and adjustments | Designed for user-friendly operation with automated features, reducing the need for constant manual adjustments |

| Yarn Handling | Handles standard yarn types efficiently | Can handle a variety of yarns, including specialty and high-performance fibers |

| Fabric Quality | Produces quality Single Jersey fabric | Capable of producing high-quality fabric with improved consistency and reduced defects |

| Maintenance | May require more frequent maintenance | Often designed for minimal maintenance, with self-diagnostic features for quick issue resolution |

| Cost | Generally more affordable compared to modern machines | Initial investment may be higher, but modern machines often provide better long-term cost-effectiveness due to increased efficiency |

| Technology Integration | Limited integration of modern technology | Integrates cutting-edge technology for enhanced performance and adaptability |

Mahedi Hasan working as an Executive (Fabric Marketing) at Pengnuo Group. Graduated with B.Sc. in Textile Engineering. Before was a Top Rated content writer at Upwork, and Level 02 Seller at Fiverr, Level 02 Publisher at Ezoic. Very passionate about content writing, SEO practice, and fashion website designing. Highly Experienced fashion writer for the last 4+ years. Have extensive 7 years of experience in the wholesale clothing business.