What is step cleaner in textile?

In the textile industry, a step cleaner is a common machine used in a blower room. It is used to open and clean by opposite spike action, remove heavy impurities, and make smaller tuff cotton.

A step cleaner, ultra cleaner, or super cleaner machine is one of the most important machines used in the blowroom section of the spinning industry. This major beating type of machine is used for opening and cleaning the impurities from the cotton tuft.

Table of Contents

Basic Action of Step Cleaner:

- The action of the beater.

- The action of opposite spikes.

- The action of air current.

Objects:

- To open & clean cotton tuft by opposite spikes and beating action

- To open the lumps of cotton into small pieces.

- To clear the cotton suitable for processing to the next machine.

- To remove heavy impurities such as leaves, and sand, without damaging the fiber.

- To convert or make the cotton tuft to the small size of cotton fiber.

Characteristics

- Beating Type: Major beater M/C [Beater, Opening & Cleaning]

- Courser Cleaner

- Fine Tuff Size

- 30-40% cleaning

- 6 beater or cylinder

- 450 Upward Machine Position

- Impurities pass over between two grid bar

- Blade or Flat grid bar used

Working principle:

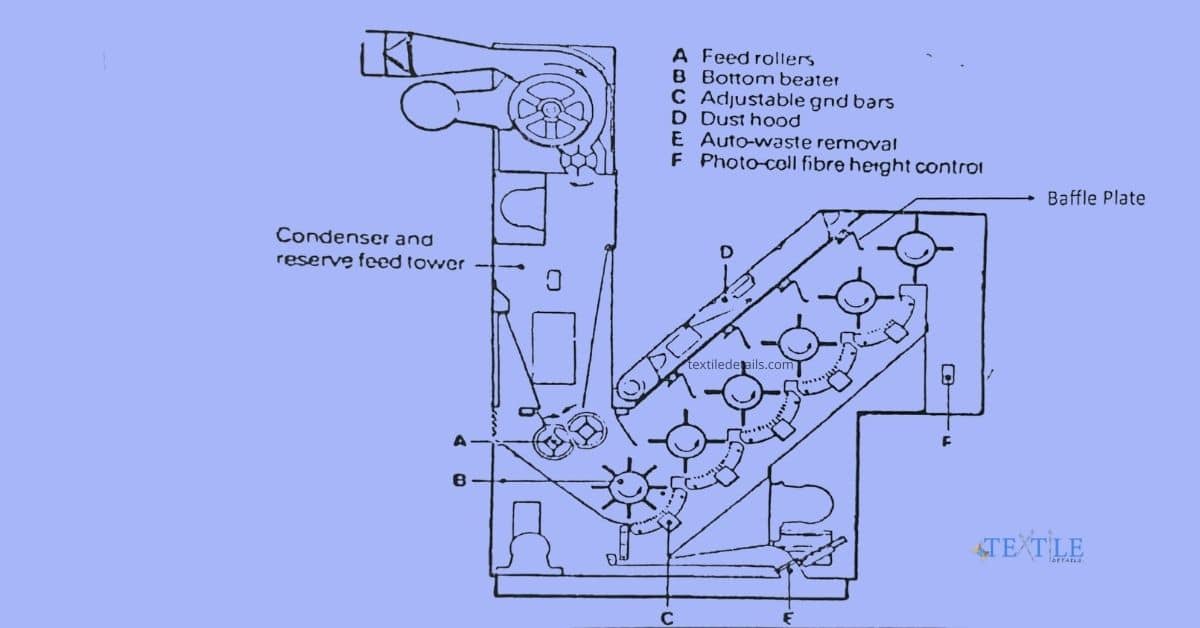

Cotton is fed from the reserve tower by a pair of feed rollers. Later it passes to the first beater. From there it is transported upwards by the six (sometimes 4) beater rollers, each carrying profiled bars, the beaters arranged on a line inclined upwards at 450. As you can see in the diagram.

The step cleaner machine diagram is as follows:

The trashes are extracted with the help of opposite spikes and beating functions. It pulls the trash and falls into the chamber through the grid bars hole. Cotton tuft opens and makes small-size tuft with beating action. A baffle plate is in the middle of two beaters, and it controls the flow of material.

Elimination of impurities occurs during the continual passage of the material over the girds arranged under the

beaters. The grids are continuously adjustable and usually also the beater speed.

How to increase beating action in step cleaner?

– By increasing the beater speed

– Increase grid bar

– Increase grid bar angle -150 (Max), 00, – 150

Machine Parameters:

General Information

| No of beater | 6 |

| No. of grid bar | 5 sets |

| No. of grid bar in every set | 20 – 25 |

| Cleaning efficiency | 40% |

| Production /hour | 750 – 900 Kg. |

| Cleaning Ability | High, applicable for all grades of cotton. |

| Beater to grid bar | 1.75 inches |

| Beater to beater | 5 inch |

| Speed | 450 to 800 RPM. |

Step Cleaner Machine Parameter

| Output Deliver | 800 kg/ per hour |

| Working Width | 1060 |

| No of Cylinder / Beater | 6 |

| Spike Type | Round |

| Cylinder Dia | 455 |

| Speed of Cylinder/ Beater Speed | 462, 510, 562, 655, 722 RPM |

| Grid Bar Type | Blade or Flat Type |

| Number of Grid Bar | 1,2,3 Cylinder 31 Set 4, 5 Cylinder 33 Set |

| Grid bar angle | +150 to – 150 |

| Grid Bar to Spike Setting | Fixed |

Video:

Reference: Lecture of Padma Kishore Dey