Do you know Yarn Manufacturing Process? Here we will learn about yarn and how it is made in two segments. You can use the jump to content index section to review a specific portion.

What is Yarn?

Yarn is a continuous strand of fibers. That’s the most straightforward way to put it. It’s a constant stretch of interlocked fibers used to create apparel and garments, as well as crocheting and knitting, weaving, embroidery, and rope making. This means that we can categorize yarn into two distinct categories.

Embroidery thread and sewing machine thread. As well as threads used in crafts like knitting and crocheting are all long lengths purchased as yarns. An alternative is a fabric, which is then knitted or spun into cloth. Rather than buying the thread individually, the wool is obtained as long cloth.

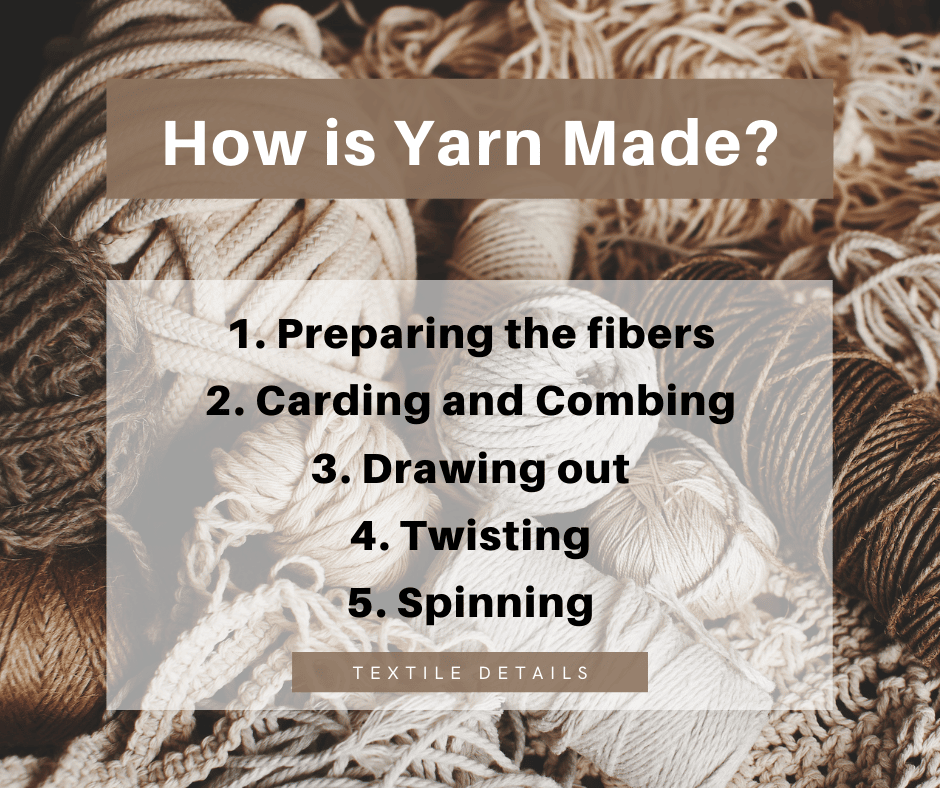

After knowing what yarn is, you might ask yourself how it is made? Right!

How is it Made?

The three primary spinning methods are cotton, worsted or long-staple yarn, and wool. All of these techniques can be used to produce synthetic staple fibers. The cotton process is listed further down since it produces more yarn than the other two.

1. Preparing the fibers

Fibers are delivered in bales, which are manually or mechanically opened. Natural fibers can need to be cleaned, but synthetic fibers only need to be separated. The picker loosens and removes the fibers lumps and cleans them if possible.

Specific applications can necessitate the mixing of various staple fibers. Blending may occur during lap forming, carding, or drawing out. The quantities of each fiber are meticulously calculated, and their proportions are maintained continuously.

2. Carding and Combing

Hundreds of fine wires are used in the carding system to isolate the fibers and drag them somewhat parallelly. A thin web of fiber is formed, and as it travels along, it passes through a funnel-shaped device, resulting in a ropelike strand of parallel threads. Blending can be accomplished by combining laps with various fibers.

Fibers are subjected to a more paralleling process when a smoother, finer yarn is desired. Short fibers emerge from the strand due to a comb-like system that arranges threads into parallel shapes.

3. Drawing out

The fiber mass after carding or combing is referred to as the sliver. Before this step, several slivers are mixed. The sliver is elongated into a single more uniform strand by a series of rollers spinning at varying speeds before being fed into large cans with a slight twist. During carding, slivers are drawn twice.

4. Twisting

The sliver is fed into a roving frame mechanism, which lengthens and twists the fiber strands. The roving is the term for these strands.

5. Spinning

Ring and open-end spinning are the two most popular commercial yarn-forming processes. The roving is fed from the spool using rollers in ring spinning. The roving, which passes through the eyelet and continues down, is elongated by these rollers.

The sliver is fed into a roving frame mechanism, which lengthens and twists the fiber strands. Ring spinning and open-end spinning are the two most popular commercial yarn-forming processes. The roving move is skipped in open-end spinning and via the traveler.

The traveler rotates around the stationary ring at a rate of 4,000 to 12,000 revolutions per minute. The bobbin is rotated at a steady speed by the spindle. The yarn is twisted and wound in one operation due to the traveler’s movement.

After knowing what yarn is and how it is made, let’s learn about the characteristics of the yarn.

What is the yarn used for?

Yarn uses to make dishcloths, towels, dish draining pads, sink liners, hot plates or trivets (wool is best), pot holders, glass cozy, cutting board mats, and more in the kitchen.

Yarn is also used in our daily wear. Such as shirts, pants, Hats, scarves, shawls, jackets, sweaters, slips, blouses, bras, lingerie, stockings, slippers, gloves, handbags, hankies, ties, long trousers, shorts, swimming suits, and other items can be made with yarn.

Building padding, rugs, pillows, blankets, mattresses, curtains, and other soft items are on the list for homes (due to all the heavy bits of furniture). Yarn can be used to make almost anything soft (and is).

What is Yarn - How is it Made? Reference Book: Yasir Nawab (Ed.) Textile Engineering De Gruyter Textbook

Mahedi Hasan working as an Executive (Fabric Marketing) at Pengnuo Group. Graduated with B.Sc. in Textile Engineering. Before was a Top Rated content writer at Upwork, and Level 02 Seller at Fiverr, Level 02 Publisher at Ezoic. Very passionate about content writing, SEO practice, and fashion website designing. Highly Experienced fashion writer for the last 4+ years. Have extensive 7 years of experience in the wholesale clothing business.

Hi, Thank you for the very well-written blog regarding the yarn and yarn manufacturing process. This blog is very helpful for people who are new to the industry and want to learn about textile-related things. As I have noticed spinning is a very crucial process in yarn making, so I thought it is worth mentioning a spinning can manufacturer recently I came upon called Jumac Cans. I would suggest you check them out.

Great blog! I am loving it!! Will be back later to read some more. I am bookmarking your feeds also