OZDNM-300 MODEL OZONE GENERATOR

Suitable for R&D applications in denim such as backstaining, reducing color, and water-treated ozone process. Features include easy-to-use PLC Software•, modular ozone units, modular oxygen units, air dryers, and ozone destruct units for gas discharge. Manufactured in accordance with the norms. A sustainable ozone wash machine system is needed for the garments industry.

Table of Contents

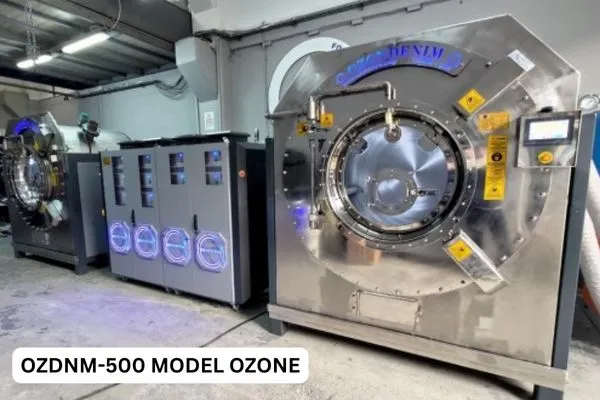

OZDNM-500 MODEL OZONE GENERATOR

Suitable for larger amounts of R&D applications in denim such as backstaining, reducing color, and water-treated ozone process. I tis one the best ozone generator. Features include easy-to-use PLC Software*, modular ozone units, modular oxygen units, air dryers, and ozone destruct units for gas discharge. Manufactured in accordance to the @ norms.

| MODEL | OZDNM – 300 | OZDNM – 500 |

| Ozone Units | 6 Units (50 gr/hr) | 10 Units (50 gr/hr) |

| Ozone Control Rate | 300 gr/saat | 500 gr/hr |

| Ozone Control Rate | 100 – 200 – 300 gr/hr Adjustable | 20% – 40% – 60%- 80% -100% gr/hr Adjustable |

| Oxygen Production Rate {m3/hr) [Oxygen Purity 93%] | 3.0 nm3/h(6 Standard Oxygen Generators) | 4.5 nm3/h(10 Standard Oxygen Generator |

| Air Dryer (For Oxygen Generators Air Input) | 1 Unit (900 It/min) | I Unit (1200 It/min) |

| Connecting Pipe for Dryer Air Inlet | 12 mm | 16 mm |

| Connecting Pipe For Ozone Input | 0.50 Inch (1/2″) | 0.50 Inch (1/2″) |

| Ozone Cabinet Dimensions (mm)[Depth x Width x Height] | 750 x1300 x 1900 | 750 x 2300 x 1900 |

| Ozone Control System | PLC Control | PLC Control (Optional*) |

| PLC Controller | GMT (Turkey) (Optional•) | GMT (Turkey) (Optional•) |

| PLC Touch Screen | 7″ GMT (Turkey) | 7″ GMT (Turkey) |

| Electronic Group | Schneider Relays & Contactors | Schneider Relays & Contactors |

| Ozone Cooling System | Air Cooled | Air Cooled |

| Working Conditions (Ozone Room) | Max. 23•C | Max. 23•C |

| Total Energy Consumption(Including Destruct Unit) | 4,8 kW | 8 kW |

| Warranty | 1 Year | 1 Year |

OZDNM- 1000 MODEL OZONE GENERATOR

Suitable for ozone applications of medium bulk production in denim such as backstaining. reducing color and water-treated ozone process.

Features include:

- New water-cooled ozone plasma technology

- PSA Oxygen System for oxygen output (Includes air dryer and tanks)

- New generation inverter control system (Helps prevents fluctuations in the mains frequency and minimizes mechanical failures)

- Easy to use PLC Software•

- Water Chiller Unit

- Ozone Destruct Unit

- Can be adapted to existing ozone wash machines (tumblers)•

- Manufactured in accordance with the norms.

- 1-Year International Warranty

| MODEL | OZDNM 1000 |

| Ozone Units | 2 Module (Includes 10 Plasmas) |

| Ozone Production Rate (gr/hr) | 1000 qr/hr |

| Ozone Control Rate | 50% – 100% – Adjustable |

| Oxygen Production Rate {m3/hr)(Oxygen Purity 93%) | 9.0 nm3/h (I PSA Oxygen Generator) |

| Air Dryer(For Oxygen Generators Air Input) | Unit (1800 It/min) |

| Connecting Pipe for Dryer Air Inlet | ¾” |

| Connecting Pipe For Ozone Input | ¾” |

| Recommended Ozone Room Dimensions(mm) [Depth x Width x Height] | 3500 x 3500 x 2750 |

| PLC Controller | GMT |

| PLC Touch Screen | 7” Touch Screen |

| Electronic Group | Schneider Relays & Contactors |

| Ozone Cooling System | Water Cooled (Chiller) |

| Working Conditions (Ozone Room) | Max. 23°C |

| Total Energy Consumption (IncludingDestruct Unit) | 14.5 kW |

| Warranty | 1 Year |

OZWM-60 MODEL R&D OZONE WASH MACHINE

OZWM-60 is designed for efficient back staining & humid wash. OZWM-60 features an AISI 304 Stainless Steel drum with 1050mm x 620 mm diameter. Features include a main door dry ozone inlet to the tumbler, an automatic safety door lock system, an ozone destruct unit, and an inverter. All controls are operated from the PLC system of the ozone generator. 1-Year International Warranty Manufactured in accordance with the norms.

Features include:

| OZONE WASH MACHINE MODEL | OZWM – 60 |

| Drum Diameter (Depth X Width) | 620 x 1050 mm |

| Drum Material | AISI 304 |

| Drum Thickness | 2 mm |

| Drum Capacity (Lt.) | 580 lt. |

| Motor Energy Consumption | 1,2 kW |

| Ozone Destruct Unit Energy Consumption | 3,5 kW |

| Invertor | 0 – 30 RPM Adjustable |

| Relays | Schneider Electric |

| Air Inlet | 8 mm |

| Ozone Gas Inlet | ½” |

| Energy Consumption | 380 V / 50 Hz |

| Dimensions [Depth x Width x Height] | 1500 x 1700 x 1800 mm |

| Weight | 1400 KG |

OZWM-200 & OZWM-260 OZONE WASH MACHINE

OZWM-200 & OZWM-260 are designed for efficient back staining & humid wash. OZWM-200 & OZWM-260 features an AISI 304 Stainless Steel drum with 1500 mm x 1250 mm, or 1400 mm x 1700 mm diameter. Features include a main door dry ozone inlet to the tumbler, an automatic safety door lock system, an ozone destruct unit, and an inverter. All controls are operated from the PLC system of the ozone generator, 1 Year International Warranty. Manufactured in accordance with the norms.

Features include:

| OZONE WASH MACHINE MODEL | OZWM – 200 | OZWM – 260 |

| Drum Diameter (Width x Length) | 1500 x 1250 mm | 1400 x 1700 mm |

| Drum Material | AISI 304 (SS 304) | AISI 304 (SS 304) |

| Drum Thickness | 2 mm | 2 mm |

| Drum Capacity (Lt.) | 2100 It. | 3500 It. |

| Motor Power | 1,5 kW | 2,2 kW |

| Hydrulic Power | 1.1 kW | 1.1 kW |

| Ozone Destruct Unit Energy Consumption | 3.5kW | 3.5kW |

| Invertor | 0 – 30 RPM Adjustable | 0 – 30 RPM Adjustable |

| Relays & Electric Group | Schneider Electric | Schneider Electric |

| Air Inlet | 10 mm | 10 mm |

| Ozone Gas Inlet | ¾” | ¾” |

| Energy | 380 v / 50 Hz | 380 v / 50 Hz |

| Tumbler Diameter (W x L x H) | 2350 x 1950 x 2300 mm | 2900 x 1950 x 2300 mm |

| Weight | 2150 KG | 2650 KG |

OZONE WASHING PROCESS & METHODS

Backstaining Process (cleaning pockets etc.)

The most commonly used process is backstaining of garments, in which you can clean the garments and their pockets by applying the dry ozone method. This method has helped reduce a significant amount of dispersing chemicals from traditional wash cycles.

Denim Color Reducing Process (bleaching method)

With denim technology advancing each day ozone color-reducing process has become an important step in helping reduce water, chemicals, and energy costs. With this process, you apply ozone to extracted garments in a dry wash machine (tumbler) and bleach them to a desired color. This method is now used widely around the world with sustainability measures becoming an important issue.

Water-Treated Ozone Process (Ozone in Water)

By mixing ozone into water you’re able to help reduce the color of the denim in a more controlled environment. Also because ozone acts as a chemical agent in the water you’re helping to clean the garments without any dispersing chemicals.

Most importantly when ozone is mixed in water it helps get rid of the denim indigo dye color which heavily affects the environment. Thus this helps reduce water treatment plant costs of denim washing factories.

Md Al Amin is a writer and originally from Bangladesh. He has a bachelor’s in Physics from the National University of Bangladesh. Completed Post Graduate Diploma in Garment Business (PGD-GB) from Institute of Business Administration University of Dhaka.