To make any garment, we require a blueprint to show how a fabric should be cut and assembled. Pattern making in the textile industry works precisely like that. Pattern-making is a craft that is based on the designer’s ideas and sketches to predict consistency and accuracy. Learn more about pattern making, its various methods, and its importance in textiles.

Table of Contents

What is Pattern Making in Textiles?

The pattern is a hard paper on which the pattern master draws different components of apparel. The complete process of producing pattern is called pattern making. Today, It can be made digitally through the CAD system.

Definition: The making of exact image of each part of a garments with flat hard board paper is call pattern making.

Pattern-making refers to creating a garment blueprint with a pattern to be used as a template to cut out fabric to sew a garment. The pattern depends on fabric types, the consumers, or any trims.

Moreover, pattern-making is the magic of any ‘ behind the scene’ situation that turns your 2D drawing into the clothing on a 3D body by bridging the gap between conceptual design framing and actual creation.

Types of Pattern

- Basic Block: Known as block pattern. Very first pattern made without any shape or allowance.

- Working Pattern: Known as garments pattern: The pattern with shape and allowance.

- Production Pattern: The pattern which is approved by the buyer is called production pattern. It’s also known as approved pattern.

There is very tiny difference in between them. So let’s discuss their differentiate factor.

| Block Pattern | Working Pattern |

| i) Made according to ideal measurement of body. | i) Made according exact measurement of body. |

| ii) No allowance is considered | ii) Seamallowance, trimming allowance are considered. |

| iii) Individual composed can’t be separated. | iii)Can be separated. |

| iv) No indication of grain line. | iv) Indication of grain line. |

| Working Pattern | Production Pattern |

| i) Sample garments are made by this pattern. | i) Production garments are made by this pattern. |

| ii) This pattern is made on the basis of basic block. | ii) No basic block is used for haking this pattern. |

Factors Effecting Pattern Making

a. Skill

b. Experience

c. Style of garments.

Pattern Making Tools:

- Manual: Pencils, Rubber, Curve, Scale, Table, Chalk, Threshing Wheel, etc.

- Computerized: Computer, Scanner, Printer, etc.

Flowchart of Pattern Making

Garments Design/ Image➡️Manual / Computer

⬇️

Basic Block

⬇️

Working Pattern ➡️Manual / Computer

⬇️

Sample Garments ➡️Manual / Computer

⬇️

Problem in Production

⬇️

Costing➡️Approved ➡️Sales Representative

⬇️

Production Pattern ➡️Manual / Computer

Methods of Pattern Making

There are around three methods of pattern-making. They are Drafting, Draping, and Flat paper. The description is below:

1. Drafting Pattern-making Method

The drafting method involves the measurements that come from accurate measurements of a body form. Measurements- Chest, waist, hip, these have to be marked on paper. Also, the drafting method helps with basic design patterns.

2. Draping Pattern-making Method

The second draping method involves two-dimensional fabric pieces that conform to the shape. Through draping, the designer can see the entire design of the finished garment. It is related to modeling the entire design on a body form using pinning and manipulating fabric. Also, draping can be understood as manually manipulating the fabric on a dress form to keep it as the designer wants.

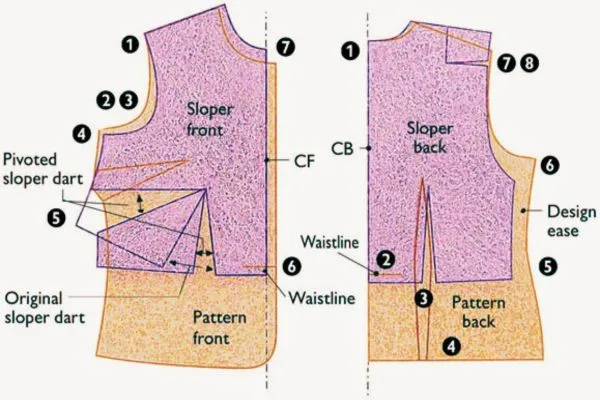

3. Flat Paper Pattern-making method

The flat paper pattern-making method develops a fitted pattern that is more comfortable to fit any body form. The method starts with a sloper that gives the body a pattern of ease to move. Also, this method, 2D pattern pieces are applied in paper or digital format.

Another method is getting popular in the textile industry: digital pattern-making.

Digital Pattern-making: It is accurate and less time-consuming. In this pattern-making, the designer can preview the final design on a digital model and alter any differences.

What is Pattern Making in Casting?

Usually, in casting, the pattern-making process creates a replica of the model of the object to be the main cast. The pattern works like a template that helps to create the final cast object. If the pattern is made of materials like wood, metal, plastic, or anything else, the replica would be the same as the desired final product. The entire process is crucial for manufacturing industries as casting pattern-making must be accurate and consistent.

Types of Pattern Making in Clothing

In clothing manufacturing, these are some of the types of pattern-making:

1. Computerized Pattern Making or CAD System

CAD, or Computer-aided design, is a system where designers can create patterns by manipulating graphical elements on the computer screen. This type of pattern-making allows the designer to change the desired shape or pattern to create new design lines and pleats.

Software used: Lectra Modaris, Gerber, Optitex.

You may like: Prototype-Making with 15 Best Pattern Making Software

Benefits of Computerized method is: Accuracy, better quality and time saving.

2. Manual Pattern Making:

Manual pattern making is done by the pattern master. The pattern master create block pattern from sketch received from the buyers’ designer or merchandiser with standard body measurements.

Types of Manual pattern making are as:

- Flat Method: Made from standard body measurements.

- Modeling Method: Made from dummy or live model which is known as toile. Upon the toile ‘calico fabric’ has been put. Then it’s measured by removing the toile. It’s time consuming method.

5 Importance of Pattern Making

Each garment we see in the market has different names and patterns. Sometimes, the pattern names become the clothes’ names. Creating a new pattern is a necessity in this rapidly changing clothing world. Without a pattern, the designers cannot express their thinking style. Here are the five important aspects of pattern-making in the textile world. They are:

- Pattern-making serves cutting fabric in less time.

Thousands of pieces of fabric can be cut with a single pattern of a design. All the credit goes to the pattern-making. Hence, it is important to create a pattern before any design.

- Pattern-Making Brings New Designs

Pattern-making is the gateway to introducing new designs. With the pattern-making process, a design is directly implemented on the fabric.

- Pattern-making Creates a Market for Employment

In this fashion industry, the pattern-making process requires employees. Some students take up the subject of design and pattern-making as a profession. For them, pattern-making is a hub of opportunity to accelerate their careers.

- Easy to customize or personalize with Pattern-Making

Pattern-making brings new designs that can be saved for many days. It is possible to customize the pattern fabric or customer requirement with the help of the pattern-making process.

- Pattern-making promotes Innovation and Creativity.

Pattern-making always involves transforming various design concepts into tangible products like clothes. The expertise of designers reflects creativity and innovation.

Pattern Making Process

The pattern-making process involves the creation of the correctly sized pieces to complete the garment. The process involves several steps. Such as:

Pattern Grading: The process of scaling a pattern to a different size by increasing or decreasing the size is called pattern grading.

- Step 01: Taking Measurements

The drawing of a garment maintains accurate measurements.

- Step 02: Creating foundational patterns

If the designer has completed the garment drawing, the drawing will be transformed into the sample pattern making by adding shapes to the garments.

- Step 03: Developing Sample Pattern

The patternmaker can use any technique in developing the sample pattern. The technique can be geometric rules to alter any pattern. Also, the patternmaker can translate into a design that can be draped. This step makes the necessary adjustments to make the perfect fit. It also goes through grading to ensure consistency and fabric pattern piece layout to optimize efficiency.

- Step 04: Developing Sample Garment

With this initial pattern, a sample garment is developed. So, in this stage, it is easy to modify or manipulate any design elements or adjustments.

- Step 05: Constructing a small batch of sample Garments

After the sample making, the manufacturer initiates a small batch of sample garments to test the market.

Conclusion

The unseen fashion designer is crafting patterns, converting imaginative concepts into practical apparel. Pattern makers provide accuracy to the skill of making clothes, from painstaking measurements to complex manipulations. In the ever-changing world of fashion, their expert workmanship guarantees that every piece fits flawlessly, balancing flair with usefulness.

Mahedi Hasan working as an Executive (Fabric Marketing) at Pengnuo Group. Graduated with B.Sc. in Textile Engineering. Before was a Top Rated content writer at Upwork, and Level 02 Seller at Fiverr, Level 02 Publisher at Ezoic. Very passionate about content writing, SEO practice, and fashion website designing. Highly Experienced fashion writer for the last 4+ years. Have extensive 7 years of experience in the wholesale clothing business.