Pattern-making refers to the initial process of developing a blueprint of various garment pieces. Pattern-making or pattern-cutting is also a condensed version of the process of making and cutting patterns. This article will discuss the overall grading process in pattern making.

Table of Contents

Pattern Grading Vs. Pattern Making

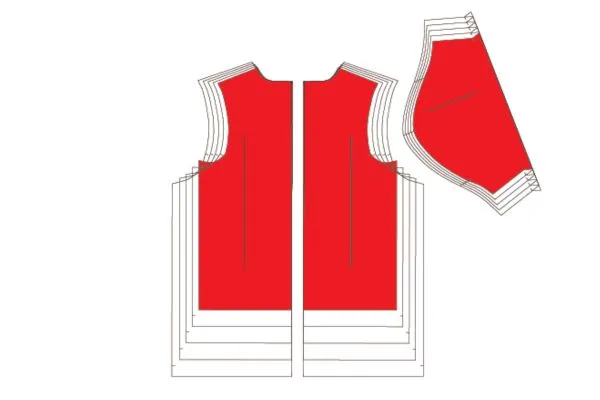

Pattern-grading refers to the technique used in increasing or decreasing the size of the garment. In a simple sense, grading has the function of seeing the proper fit for the other size without changing the basic style of the original model. Pattern grading allows you to maintain the essence of the garment without making any changes in the shape, fit, or dimensions.

Meanwhile, the pattern-making process involves taking measurements, creating drafts of the initial pattern pieces, and adjusting to fit and style. Pattern making represents the set of patterns for a specific size and the design concept so that it is easier to create a sample garment.

Methods of Grading in Pattern Making Process

There are a few methods that apply to the wide umbrella of grading in the pattern-making process. The overall aim is to create a range of sizes for a particular clothing design. So, the crucial grading step in apparel production allows today’s manufacturers to maintain design proportion and aesthetics using many methods.

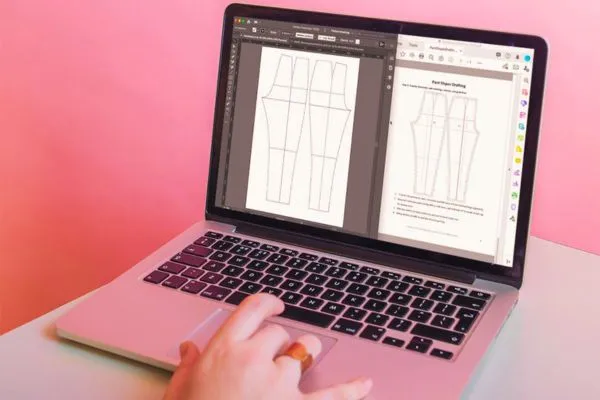

Method 01: Computer Grading

In the pattern-making process, the makers can use grading software or computer-aided design (CAD) software to grade, automate the process, and ensure the accurate resizing of pattern pieces.

Method 02: Manual Pattern Grading

Manual pattern-grading in the pattern-making process involves these steps:

- Base Pattern:

The Base Pattern is the first grading step created with precise measurements.

- Size Breakdown:

In the case of industrial manufacturing, based on the target market and demography, the sizes will be graded and determined into small, medium, large, and extra-large. It also depends on the specific market and the brand of the garment.

- Test Garments & Final Adjustments:

After patterns are created for all sizes, sample garments will be produced. In those samples, fit and design will be checked, and necessary adjustments will be made by pattern-making makers. Grading will note every change made to each garment pattern for each size, and then mass production will start in full-fledged.

Conclusion

Considering the design consistency, grading in pattern making is essential for catering to the fashion industry’s diverse body types and sizes. The grading also ensures that a piece of garment can be well-manufactured for a wider audience to uphold inclusivity and accessibility.