Sampling is the method that is used to form materials like yarn, fiber, or fabric. We can learn about the amount of materials available in the sampling through sampling. We can find the nature of the test. We can see the testing instruments that are used in sampling. So we can know the information that we require.

Table of Contents

What is a Sample?

A sample is a relatively small fraction that is selected to represent a population. i.e., a sample is a selected separate unit or part that means a lot, consignment, or design. A sample is used to illustrate the qualities and the defects of the whole lot.

Say: Using a suitable sampling method, 20mg of cotton fiber was selected to test the staple length of the cotton fiber from 500lb of the cotton bale.

So, Sample Weight: Bale weight = 20:(500*453.6*1000)

= 20: 226800000

= 1: 11340000

Thus, less than one eleven millionth of the bulk has to represent the bale.

What is Sampling?

Sampling: Sampling is a process used in statistical analysis in which a predetermined number of observations are taken from a large number. The tests carried out on the sample represent the bulk material.

The object of sampling is to produce an unbiased sample in which the proportions are the same as those in the bulk.

Some sampling-related terms:-

1. Laboratory Sample

2. Bulk Sample

3. Specimen or Test Specimen

4. Test lot or batch

5. Consignment.

1. Laboratory Sample: The final sample on which the tests will be carried out is the laboratory sample.

2. Bulk Sample: Bulk samples are also referenced as production samples or final production samples. Which is an actual unit of the order’s final production.

3. Specimen: It is defined as a sample that is selected for testing in a laboratory. This is the one that will be used as a basis for measuring the laboratory.

4. Test lot or batch: This consists of all the holders of a cloth material of one defined type and quality, delivered to one client according to one dispatch note. The material is presumed to be uniform, so this is the whole material whose properties are to be characterized by one set of tests.

5. Consignment: The quality of material delivered at the same time. Each consignment may consist of one or many lots.

Why random sampling is better than biased sampling?

Random sampling is better than biased sampling. Here are some reasons why random sampling is better than biased sampling.

Equal Chance: In random sampling, every individual in the population has an equal chance of being included, and in biased sampling, every individual in the population has no equal chance of being included. So, Random sampling is better.

Physical Characteristics: Random sampling is not influenced by physical characteristics. On the other hand, biased sampling is influenced by biological factors.

Dependency on position: Random sampling is not dependent on the position of the sampling person, and biased sampling is dependent on the position of the sampling person.

Representative: Random sampling represents the bulk, and biased sampling doesn’t mean the bulk.

So, we can say random sampling is considered best, and biased sampling may be negligible. That’s why random sampling is better than biased sampling.

Objects of sampling

- To prevent the wastage

- To reduce cost.

- To assure good quality.

- To know the perfect characteristics of the population.

- To avoid the destructive nature of many trials.

- To increase the quality of population/ raw materials

Types of Sampling Method

Specifically, there are two types of sampling methods:

- The Random sampling methods.

- The Biased Sampling Methods.

- Numerical Sample.

1. Random sampling methods: In the Random sampling method, every individual in the population has an equal chance of being included. The number in the sample must be sufficiently large to fit all the variations of the individuals in the population. It is free from bias, therefore truly representing the population.

2. The Biased sampling method: In the biased sampling method, the selection of an individual is influenced by factors rather than chance. The cause of the bias may be the physical characteristics of the existent position of the person doing the slice. The longer fibers are more likely to be selected from a strand of materials than the short fibers.

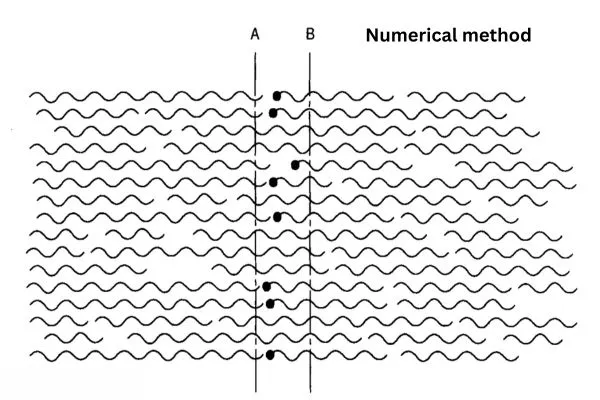

3. Numerical method: A sample in which the proportion by the number of, say, long, medium and short fibers would be the same in the sample as in the population. This is called the numerical method.

Methods of fiber

Fiber Sampling Techniques:

Since 100% fiber testing is impossible, random sampling is done. There are some types of ways used in fiber testing. Here is a description of some techniques.

- The Squaring technique

- The cut-squaring technique

- The Zoning technique

- Tong sampling method

- Dye sampling method

- The core sampling method.

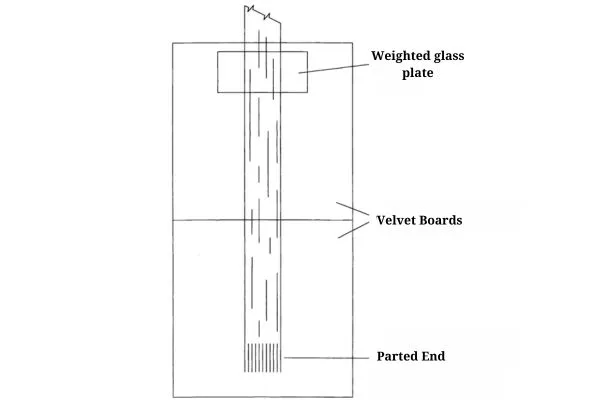

- The squaring Technique:

- The silver is opened into a web and placed on a black velvet pad.

- The end of the splinter is also squared off.

- A glass plate is placed over the fibers to act as a control, and a small fringe is left projecting beyond the edge of the plate.

- All the protruding fibers are removed and discarded.

- The plate is moved back a little, and an alternate borderline is removed.

- The plate is pushed back a little, and a second fringe is removed.

- Apparently, the extent baas have been avid since all the ends of fibers have terminated in a given volume.

- Repeat the operation until the final position of the plate edge was at least a distance equal to the length of the most extended fiber present from its original position.

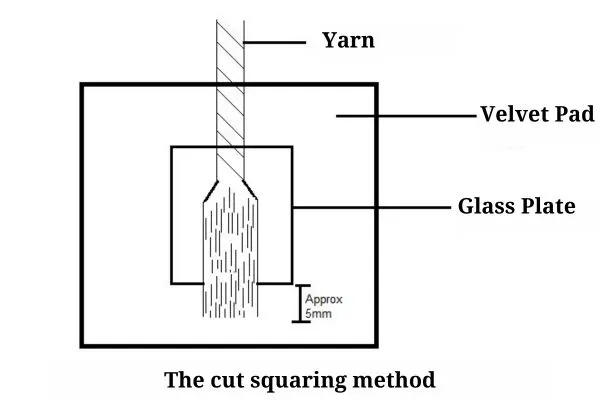

2. The cut squaring method:

A modified squaring technique may be used where the material is composed of fibers in parallel order, e.g., sliver, roving, and yarn.

- The twisted material forms are first untwisted, opened out a little, and laid parallel on a black velvet pad.

- A glass plate is placed over the fibers with its leading edge at right angles to the strand axis.

- The fringe is cut across with scissors near the glass ends of the project.

- Plate as much as possible and the cut fibers are removed by forceps and discarded.

- The glass plate was moved back about 1mm, and the processing fringe was removed and discarded.

- This operation is repeated.

- Finally, after a third movement of the gas plate, the fringe is removed and used as the sample.

- For wool tops and similar forms of material, it is recommended that the leading edge of the glass plate be put at an angle of about 600 to the stand axis and that cut should be made at a distance from the end more significant than the length of the most extended fiber present.

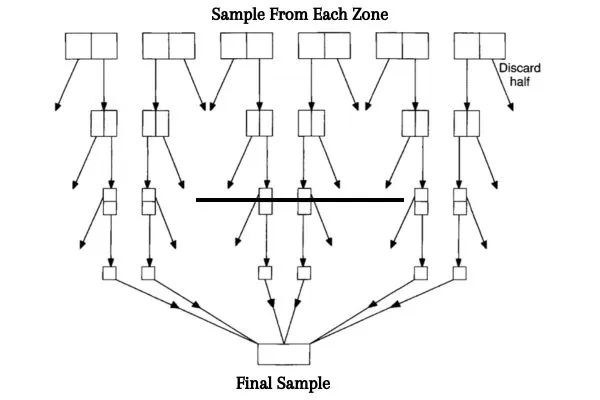

3. The Zoning Technique

- A sample that weighs two oz. (roughly 906.72 gm) is drawn by opting for about 80 large snowbanks from different corridors of the bulk.

- This sample is also divided into four corridors.

- Sixteen small snowbanks are taken arbitrarily from each part( roughly 20 mg).

- Each stack is halved four times and discarded alternatively by turning the stack through the right angle between consecutive halving. Sixteen wisps are therefore produced from each part.

- These wisps are combined to form a stack.

- Each stack is mixed by doubling and drawing between fritters.

- Each stack is divided into four corridors.

- A new stack is attained by combining a part of the four snowbanks.

- The sample is remixed by doubling and drawing.

- A quarter of the sample is removed from each stack to form the final sample.

4. Tong Sampling Method

- In the tong sampling method, an extent-biased sample is obtained. In effect, the grip of a brace of surgical tongs becomes original to the line AA in the figure.

- The material should be in a more or less parallel order so slivers, roving, and yarns can be treated this way.

- After opening the material into a thin flat sheet, one pair of tongs is used to clamp about three groups of fibers at right angles to the fiber direction.

- The clamped fibers are removed from the rest of the material and carefully combed on one side of the tongs.

- After combing, a second pair of tongs clamp the fibers on the combed side of the sample, care being taken to ensure that the limbs of both pairs of tongs are parallel to each other and in contact.

- The first pair of tongs is removed, and the uncombed fringe is combed. The fully combed sample is then transferred to a velvet pad prepared for further testing.

Importance of Sampling

Textile testing is destructive, i.e., the equipment used for testing goes to waste after testing; hence, testing all of the material isn’t desirable. As textile production is always massive and bulk, testing all the final output from a production process is impossible.

Therefore, only representative samples of the material are tested. Sampling also saves time and cost. Sampling reduces the risk of the entire population. Sampling plays a massive role in decision-making. Sampling reduces the errors that can happen.

So, we can say the importance of sampling is immense in textiles.

Conclusion

In conclusion, we can say sampling represents the entire data analysis of the sampling, the process of sampling, the methods of sampling, and the factors of sampling. The objects of sampling tell us the properties.

Reference

- http://easywaytotextile.blogspot.com/2019/07/what-is-sampling-technique.html

- https://www.studocu.com/row/document/uttara-university/merchandising/textile-testing-final-q-a-by-raihan/8031289

- https://textilelearner.net/sampling-techniques-of-fiber-yarn/

- https://www.nature.com/articles/s41598-021-01468-z

Hi, this is Taspia Binta Yousuf, A B.Sc. in Textile Engineering student at Textile Engineering College, Noakhali. My department is fabric Engineering.