In the vibrant world of textiles, achieving the perfect hue is an art. Enter the dye dosing system – a technological marvel revolutionizing the way fabrics are colored during the washing process. In this article, we’ll dive deep into the intricacies of dye dosing, exploring its benefits, challenges, and the impact it has on the quality of the final product.

Table of Contents

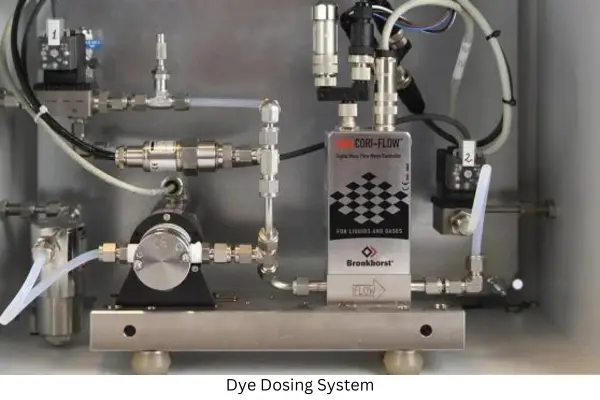

What is Dye Dosing System?

Dye dosing system is designed for mixing chemical, pigment and soft oil, then injecting it to washing or dyeing machines.

It have many optional functions for different uses. Especially full automatic dosing system, controlled by a single PLC, can program and save many injection processes, so it can be used in all kinds of washing machines and dyeing machines, no matter old model or new model.

Types of Dye Dosing Systems

1. Gravity-Based Dye Dosing Systems

Picture this: a seamless flow of dye into the washing system, guided by gravity. Gravity-based dye dosing systems rely on the natural force to ensure a steady and controlled release of dye. They are a cost-effective solution for smaller operations, offering simplicity without compromising precision.

2. Pump-Based Dye Dosing Systems

Now, let’s add a bit of power to the mix. Pump-based dye dosing systems utilize pumps to precisely inject dye into the washing process. These systems are known for their accuracy and adaptability, making them a popular choice for medium to large-scale textile manufacturers.

3. Automated Dye Dosing Systems

Imagine a dye dosing system that learns and adapts. Automated dye dosing systems take precision to the next level, employing sensors and sophisticated algorithms to dynamically adjust dye quantities based on real-time conditions. The future of dyeing is here, and it’s remarkably intelligent.

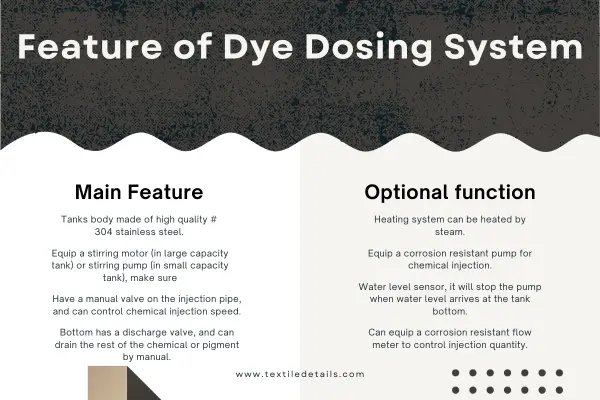

Feature of Dye Dosing System

Main Feature

- Tanks body made of high quality # 304 stainless steel.

- Equip a stirring motor (in large capacity tank) or stirring pump (in small capacity tank), make sure

- Have a manual valve on the injection pipe, and can control chemical injection speed.

- Bottom has a discharge valve, and can drain the rest of the chemical or pigment by manual.

Optional function

- Heating system can be heated by steam.

- Equip a corrosion resistant pump for chemical injection.

- Water level sensor, it will stop the pump when water level arrives at the tank bottom.

- Can equip a corrosion resistant flow meter to control injection quantity.

- Can be controlled by a single PLC and touch screen, make the injection quantity, string, heating, timing automatic.

Anyway, chemical injection can be automatically controlled and programmed independently; it is the best choice to upgrade your equipment.

| Models | DS- 50 | DS- 100 | DS- 200 | DS- 300 | DS- 500 | DS- 700 | DS- 1000 | |

| Capacity | Lt. | 50 | 100 | 200 | 300 | 500 | 700 | 1000 |

| Pump / motor power | KW | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.75 | 0.75 |

| Drum diameter | mm | 400 | 500 | 636 | 750 | 836 | 960 | 1180 |

| Drum depth | mm | 500 | 500 | 680 | 800 | 900 | 1000 | 1200 |

Dye dosing in washing systems has become a linchpin in the textile industry, ensuring that every piece of fabric gets its color just right. The precision and efficiency offered by these systems have transformed the way manufacturers approach the dyeing process.

Dye dosing involves the accurate measurement and delivery of dye into the washing system. This precise control is crucial for achieving consistent coloration across batches of fabric, a feat unattainable with traditional, manual dyeing methods.

Importance of Dye Dosing to Impact Washing Quality

Ensuring Even Color Distribution

Ever had a piece of fabric with uneven color? Dye dosing eliminates that woe. By precisely controlling the amount of dye released, these systems ensure that each thread of fabric gets the perfect amount of color, resulting in a beautifully even distribution.

Preventing Overuse or Underuse of Dye

Too much or too little – both scenarios are a nightmare in the world of textile manufacturing. Dye dosing systems act as the meticulous artists, preventing overuse or underuse of dye, thus avoiding wasted resources and subpar quality.

Addressing Environmental Concerns in the Textile Industry

Green is not just a color; it’s a responsibility. Dye dosing systems contribute to environmentally friendly practices by minimizing dye and water waste. This eco-conscious approach aligns with the growing demand for sustainable solutions in the textile industry.

Technological Advancements in Dye Dosing

Smart Sensors for Real-Time Monitoring

Enter the era of smart dye dosing. Modern systems are equipped with intelligent sensors that monitor the dyeing process in real-time. These sensors provide valuable data, allowing for immediate adjustments and ensuring that the coloration stays on point throughout the entire batch.

Integration with IoT for Remote Control

Picture being able to monitor and control your dye dosing system from anywhere in the world. IoT integration makes it a reality. Remote control not only enhances convenience but also enables quick responses to unexpected changes, maintaining the integrity of the dyeing process.

Sustainable Practices in Modern Dye Dosing Systems

Sustainability is no longer a buzzword; it’s a necessity. Modern dye dosing systems are designed with sustainability in mind. From using eco-friendly dye formulations to minimizing water consumption, these systems contribute to a greener and more responsible textile industry.

Conclusion

In the colorful tapestry of textile manufacturing, dye dosing emerges as the unsung hero. From ensuring even color distribution to embracing the latest in technology, dye dosing systems have become indispensable for businesses aiming for excellence. As the industry evolves, so do these systems, promising a future where precision, efficiency, and sustainability intertwine seamlessly.

FAQs (Frequently Asked Questions)

1. How do I know if a dye dosing system is right for my business?

Consider factors like the scale of your operations, type of textiles produced, and budget. Consult with experts to determine the best fit.

2. Are dye dosing systems only for large textile manufacturers?

No, dye dosing systems are adaptable and beneficial for businesses of all sizes, promoting consistency and efficiency.

3. Are automated dye dosing systems difficult to operate?

Not at all. Modern systems come with user-friendly interfaces, and operators can be trained for optimal usage.

4. How does dye dosing contribute to sustainability?

By minimizing dye and water waste, dye dosing systems align with sustainable practices, reducing the environmental impact of textile manufacturing.

5. Can I customize a dye dosing system to meet my industry’s specific needs?

Yes, modern dye dosing systems offer customization options, allowing businesses to tailor the system to their unique requirements.

Mahedi Hasan working as an Executive (Fabric Marketing) at Pengnuo Group. Graduated with B.Sc. in Textile Engineering. Before was a Top Rated content writer at Upwork, and Level 02 Seller at Fiverr, Level 02 Publisher at Ezoic. Very passionate about content writing, SEO practice, and fashion website designing. Highly Experienced fashion writer for the last 4+ years. Have extensive 7 years of experience in the wholesale clothing business.