The fabric structure is how threads are interlaced or looped together to form a fabric. Woven fabrics consist of warp and weft threads that are intertwined at right angles, while knitted fabrics feature yarns that are interloped.

Fabric structure and design has an impact on fabric design, as different structures create different textures and patterns. Different types of weaving can be used to create unique fabric designs.

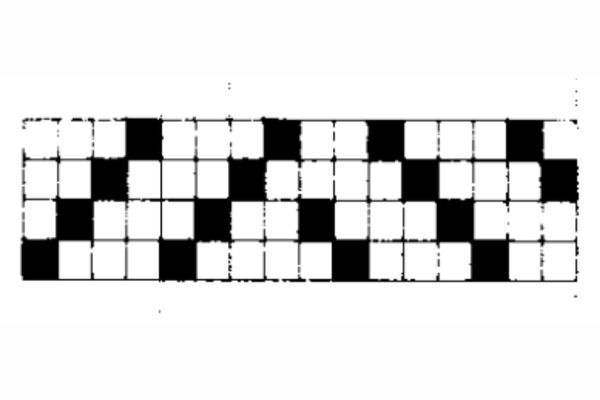

Plain weave is the basic weave for most woven fabrics, characterized by alternating over and under warp threads. The basket weave is a variation of plain weave where multiple warp and weft threads go over and under each other in groups, creating a more textured look than plain weave. Twill weaves involve diagonal lines in the fabric and can be modified to create various complex patterned fabrics.

In this article, we will know about Fabric structure and design in Details.

Table of Contents

What is Fabric Structure?

Fabric Structure: The order of interlacement of warp and weft threads at right angles [90°] is known as a structure of woven fabrics. The inter looping system of yarns is known as structure for knit fabrics.

Classification of fabric structure

There are four way of making or producing fabric, structurally. These are:

- Woven fabric structure – Interlacing of Warp and Weft Yarn.

- Knit fabric structure – Interlooping of Single set of Yarn.

- Non-woven – Melting / Felting.

- Braid Structure – More than two set of yarn.

1. Classification of woven fabric

The woven structure classified into two classes:

- Simple Structure: 90° comparatively parallel.

- Compound Structure: 90°/or not; more than series of yarn.

a. Simple structure:

Simple structure, in which the ends and picks intersect one another at right angles and the cloth are respectively parallel with each other. In these constructions, there is only one series of ends and one series of picks.

Example: plain, twill, satin.

b. Compound structure:

Compound structure in which there may be more than one series of ends or one series of picks, some of which may be responsible for the body of the fabric. In these fabrics, some threads may be found not to be in parallel formation one to another in either plane.

Example: carpet, towel, piled fabric.

Methods of fabric representation:

- Warp over weft interlacing

- Weft over warp interlacing

Fundamental factors of woven cloth structure

- The nature of raw materials used.

- The nature of yarn used.

- The count of yarn, TPI and twist direction.

- Thread density.

Important definitions of fabric structure and design

- One repeat of weave: A number of interlacing combined in both directions produces a unit of design or one repeat of weave.

- Formula number: Any structure or interlacement numerically express in a small fraction is called formula number.

- Repeat number or repeat size: No. of warp yarn and no. of weft yarn in a repeat is known as warp repeat no. and weft repeat no. Elements of a complete design for a woven fabric.

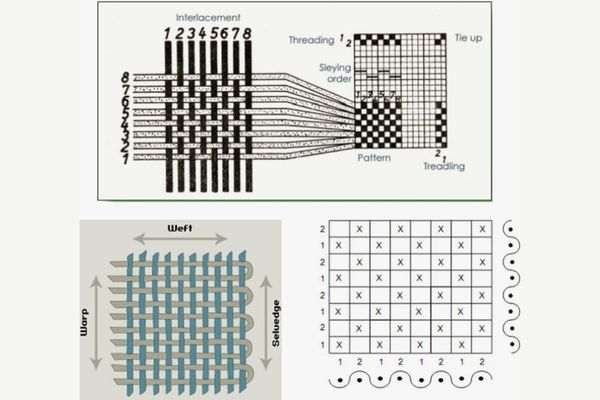

Component of a complete Design are as:

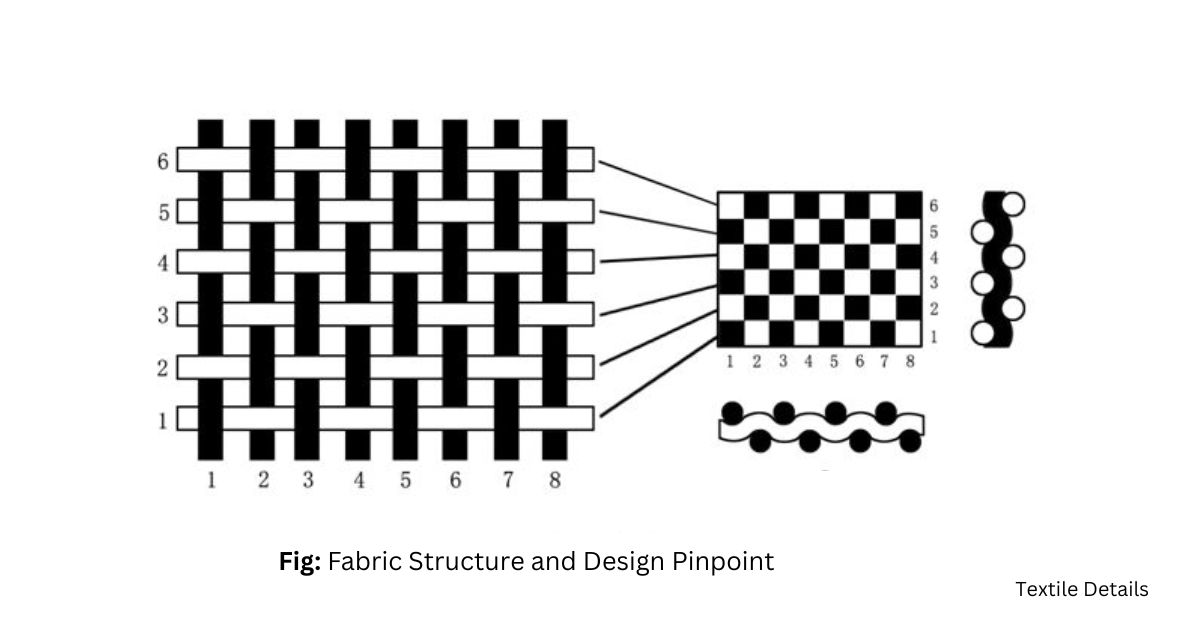

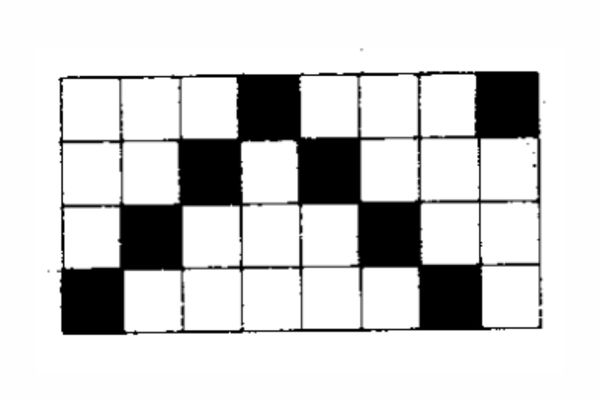

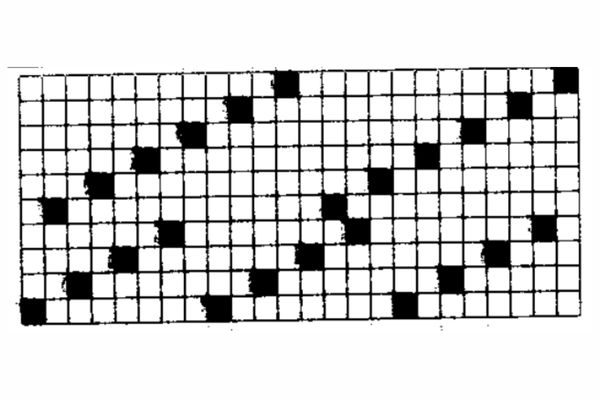

- Weave plan: To show the interlacement of warp and weft threads in woven fabric by design is called a weave plan.

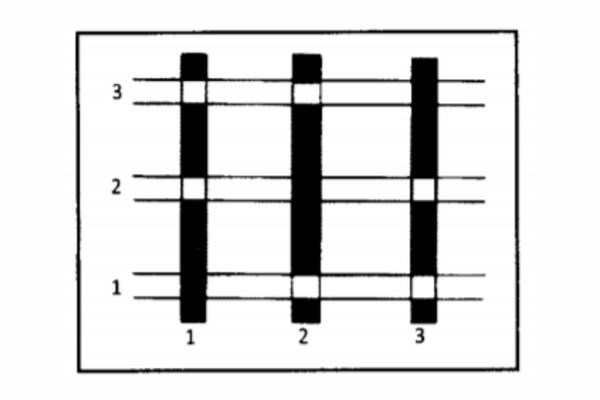

- Drafting plan: A draft indicates the number of heald shafts used to produce a given design and the order in which the warp ends are threaded through the heald eyes of the heald shafts.

- Lifting plan: lifting plan defines the selection of heald shafts to be raised or lowered on each successive insertion of the pick.

- Denting plan: Denting is the operation of drawing the warp threads, already threaded through the heald eyes in groups through the spaces between the wires of the reed.

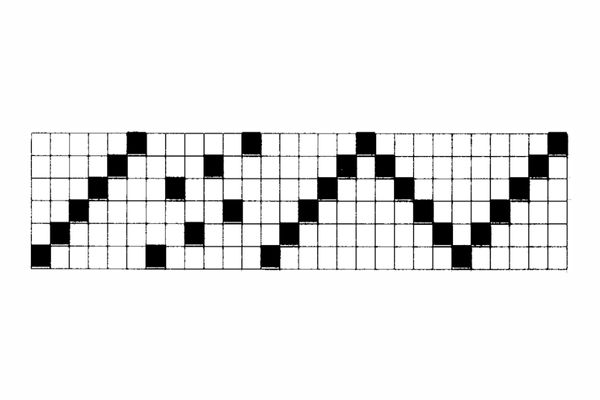

Features of a design

- The vertical lines or space are represented as a warp.

- The horizontal lines or space is represented as a weft.

- Each square indicates an intersection of a warp and a weft.

- ‘X’ (Cross) represents warp up over weft and blank space represents weft up over warp.

- There are two and only two possibilities of each crossing.

- One complete repeat should be shown on the design paper.

- Symbols indicate repeat unit.

- # Indicates starting point.

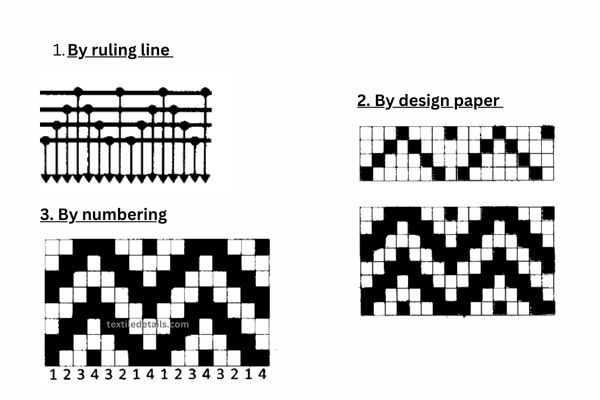

Methods of indicating drafting

- By ruling line

- By design paper

- By numbering

Systems of drafting in weaving

- Straight draft

- Pointed draft

- Skip draft

- Broken draft

- Divided draft

- Grouped draft

- Curved draft

- Combined draft

1. Straight draft

- Straight Drafting order progress successively from first first to last healed frame.

- No of Heal frame = No. of warp yarn in repeat.

- Lifting plain is same as weaving plan.

- Straight draft is the simplest type of draft, forming the basis of many other drafts.

- It is the most common draft, and it can be used with any number of heald shafts.

- Each successive thread is drawn on each heald shaft. The 1st thread is drawn through the first heald shaft and the 2nd through the second shaft and so on. So, the no of the heald shaft equals the no of warp threads in a repeat.

- Application: Twill and satin design.

2. Skip draft

- Skip draft is used in weaving the fabric with a high density of warp threads.

- Use more heal frame than minimum required for a weave.

- Skip draft use to distribute tbe warp thread more uniformly.

- Help to reduce friction and rubbing between ends.

- The no. of heald shaft used is multiple of two as the no. of threads in warp repeat.

- This enables to decrease the density of healds on each shaft and reduces the friction thread against thread and thread against the shaft.

- In the case of dividing each heald shafts into two, the odd no. of threads is drawn through the 1st set of the shaft and the even no. of threads are drawn through the 2nd set.

- Skip drafting is very suitable for weaving fabrics having heavy warp thread density.

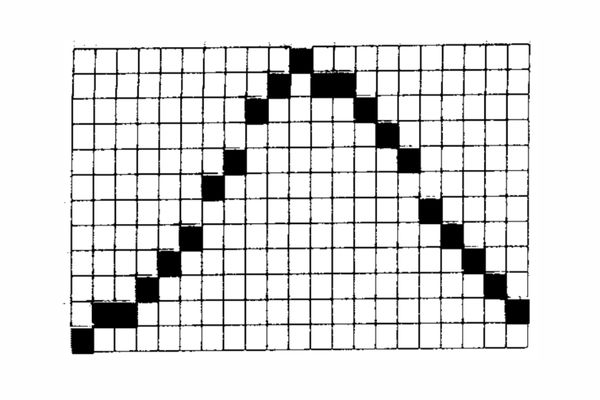

3. Pointed or V-draft

- Symmetric design.

- Similar to the straight draft but it it reversed after the half repeat warp way.

- No. of heal frame = 1/2 No. of warp yarn repeat.

- Pointed draft is used to produce fabric with symmetrical design e.g. zigzag twill, Diamond.

- This is used where the straight draft can not be pplied because aof large warp repeat.

- This draft can be considered as a combination of straight drafts.

- A straight draft is returned in the opposite direction at a predetermined point.

- Every head shafts contain 2 warp ends.

- No. of heald shafts equal to half of the no of threads in warp repeat.

- Application: Twill and Diamond Design

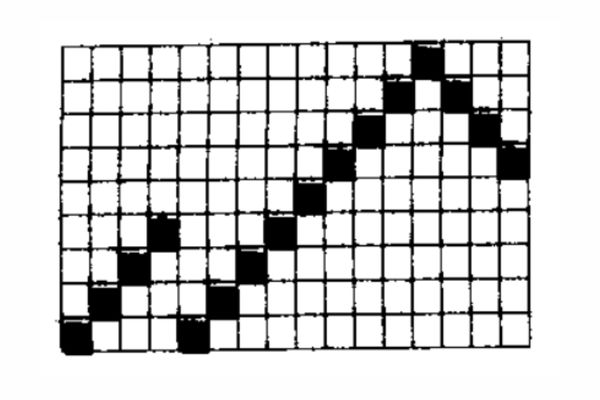

4. Broken Draft

- Almost resemble the pointed draft but the pointed effect is broken.

- Broken draft draft can be considered a modified pointed draft.

- Broken draft is a combination of straight drafts with different directions of constrictions.

- The reversal of direction is not on the last or the first shaft as in the pointed draft.

- When the direction is reversed the first thread of the next group is started higher or lower then the thread of the exceeding group.

- Application: Suitable to produce herringbone twill, diaper design.

5. Divided Draft

- The held shaft is divided into two or more groups in the divided draft.

- For every group up, a suitable draft is selected.

- Used in double warp weaves, two-ply weaves, and pile weaves, i.e. two or sets set of warp yarns are required.

- More frequently, interweaving threads are kept in the front heald shafts.

- In warp pile fabric the ground warp threads are passed through the front heald shafts, and the pile warp threads are passed through the back shafts.

- Application: Pile fabric, terry fabric, double cloth.

6. Grouped draft

- Group draft is used for producing check and stripe fabric.

- Two sets of stripes are used in two sets of heald shafts.

- Warp of each group passed through a particular group of heald shafts adjacently, and the other set of warp is inserted through another group of heald shafts adjacently.

- The repeat of the draft is determined by the number of stripes and the number of threads in each stripes.

- Application: Produce check and stripe design in fabric

7. Curved draft

- Curved draft is irregular and can not be classified.

- Used for reducing number of heal frames.

- Used to produce decorative weave with large repeat unit.

- Used to reduce the no. of heald shafts.

- Irregular drafting and not classified.

- Application: Producing fancy yarn.

8. Combined Draft

- The combined draft is produced by two or more drafts combined together.

- In producing some special types of fabrics different types of drafts must be mixed.

- It is a very complicated type of draft.

- It can be chosen if there are some technological or economic reasons.

- A combined drafting plan requires the most complicated design and great experience.

Some important factors

The weave of fabric shows the interlacing warp and weft

Contact fields :

These are the contact points between warp and weft crossing at a right angle. The number contact fields always equals the product of the number of warp and weft threads.

Contact field = RNwa X RNwe

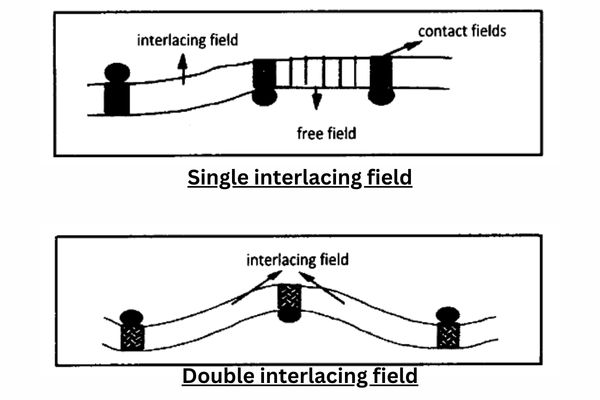

Interlacing field:

These are the points where a yarn of one system of threads changes its position in relation to other system. Interlacing fields are active fields since they provide the fabric cohesion.

Fabric Interlacing field Types:

- single interlacing field

- Double interlacing field

1. Single Interlacing Field:

The yarn bends from the top of the fabric to the bottom and covers two or more yarns.

2. Double interlacing field:

The yarn bends, covers a following yarn, bends again and reappears at the same fabric side.

Free field

These are the zones where the warp and weft yarns do not touch and do not change the fabric side. Because of the free fields, floats are formed, and the yarns in the weave may shift.

Open field

These are zones where neither warp nor weft threads occur. The number of open fields is important for air and water permeability.

How to Identify Warp and weft in fabric?

Identification of warp and weft in fabric are as follows:

- The warp yarn is more robust and finer than weft yarn.

- Weft yarn has more crimp than warp yarn.

- The selvedge always runs in all fabrics’ lengthwise (warp) direction.

- Fancy or unique function yarns are usually in the filling (weft) direction.

- Most fabrics have lower elongation in the warp direction.

- The warp yarns is straighter and are more parallel in the fabric because of loom tension.

- Warp yarns tend to be smaller, are more uniform in structure and appearance and have higher twists.

- Fabric characteristics may differentiate between the warp and weft directions. For example, denim has a warp face, satin has warp floats, and poplin has a weft rib.

References:

- https://www.coursehero.com/file/147456128/066pdf/

- Fabric Design & Structural Analysis

- https://www.textileschool.com/454/drafting-plans/

- https://textileapex.blogspot.com/2014/09/terms-of-fabric-structure.html

- https://textilestudycenter.com/types-drafting-plan/

- http://understanding-textiles.blogspot.com/

- Watson’s Textile Design and Colour – Z.Grosicki

- Watson’s Advanced Textile Design and Colour – Z.Grosicki

- Woven Cloth Construction – Robinson.

- Fabric Structure and Design – N. Gokarneshan

- Understanding Merchandising – Prof. Dr. Shah Alimuzzaman

Mahedi Hasan working as an Executive (Fabric Marketing) at Pengnuo Group. Graduated with B.Sc. in Textile Engineering. Before was a Top Rated content writer at Upwork, and Level 02 Seller at Fiverr, Level 02 Publisher at Ezoic. Very passionate about content writing, SEO practice, and fashion website designing. Highly Experienced fashion writer for the last 4+ years. Have extensive 7 years of experience in the wholesale clothing business.