Low Bath Specific Wind Storm Shower Washing Machine has a special effect on washing denim fabric. The machine is equipped with an adjustable unloading system. Through special design, it is in the rain state when rotation and the washing effect are improved.

Low bathing ( 1: 2 – 1:8)

This equipment model: ST- Y5108/4208/3208/ four kinds, you can ask the factory for the detailed technical parameters of this model.

Table of Contents

ST-W300

ST-W300 NANO ATOMIZER

Through the special nano atomization function, the machine can achieve the desired specific effect of the fabric.

ST- M DYEING/WASHING POOFING MACHINE

- It is suitable for dyeing and washing small and medium samples of various fabrics.

- Computer control.

- Automatic dehydration.

Low bathing (1:2 – 1:8)

| TECHNICAL DATA | ||||

| Model | 358 | 708 | 1308 | |

| Cylinder diameter | mm | 900 | 1000 | 1300 |

| Cylinder profundity | mm | 550 | 700 | 900 |

| Variable speed | r/mm | 0-110/500 | 0-110/500 | 0-110/500 |

| Power | kw | 3 | 5 | 7.5 |

| Length | mm | 1650 | 2050 | 220 |

| Width | mm | 1000 | 1500 | 1700 |

| Height | mm | 1500 | 1760 | 1750 |

Detailed technical parameters of the model can be obtained from the industry. The above technical parameters are subject to change without prior notice.

ST ADVANTAGES OF ENERGY-SAVING GARMENT DYEING MACHINE/WASHING MACHINE

- Versatility

- Other operations with the same machine (preparation, enzyme wash, dyeing, etc…)

- Processing at variable speeds according to the type of dyeing, finishing, and fiber (wool, silk, synthetic, cellulosic, and their blends)

- High speed = high dying quality

- Increasing dyestuff penetration and diffusion

- Better reproducibility

- Extremely reduced tangling and streaks

- Extremely reduced abrasion effect and breaking

- Miono garment manipulation = minor possibility of stains

- Minor- dyeing process and second-quality garments

- Reduced consumption

- Short liquor ratio (1:2 – 1:8)

- Water saving (60% – 70%)

- Energy saving (50% – 60%)

- Chemical products saving (50%)

- Water treatment reduced and so minor ecological impact

- Reduced Processing time

- Intermediate loading, unloading, and drying are avoidable

- Easy machine loading and unloading (0pen pocket)

- Make less time for water to heat up (short L:R)

- Improved loading capacity

- High loading capacity

- About 50% of productivity is increased if compared to a dyeing machine with divers

- Temperatures of 99 C can be achieved

- Closed machine that allows to work in reduced ambient

- Vat dyes- Sulphur dyes- Indigo dye

- Energy savings due to the reduced heat dispersion

ST — 410

ST-410 FAST ENERGY SAVING LARGE CAPACITY DRYER

- The capacity of this model is 3 times that of the traditional model, the drying time is fast and the efficiency is high.

- Take up a special energy-saving process to achieve the high energy-saving effect.

- Automated open and close the door and have an automatic flip-unloading system.

- Reduce work intensity and reduce operator.

| TECHNICAL DATA | ||||

| Model | 410 | 310 | 210 | |

| Cylinder diameter | mm | 1800 | 1760 | 1450 |

| Cylinder profundity | mm | 1400 | 980 | 1050 |

| Drum speed | r/mm | 25 -30 | 25 -30 | 25 -30 |

| Outlook size ( L ✖W✖ H) | mm | 2260 ✖2400✖ 3200 | 2200 ✖1900✖ 3000 | 2200 ✖1600✖ 2800 |

Detailed technical parameters of the model can be obtained from the industry. The above technical parameters are subject to charge without prior notice.

STH- 310

STH- 310 ENERGY-SAVING DRYING MACHINE

Saving steam 10-20 minutes 30% – 50%, shortening drying time.

The fan directly heats energy into the energy-saving dryer cylinder, to solve the general dryer directly outside the row of heat caused by the vast heat energy waste, energy saving, and high effect.

The outer barrel and heat exchanger energy-saving dryer installed insulation cotton, effectively prevent heat loss.

Humidity can be controlled automatically.

Detailed technical parameters of the model can be acquired from the factory. The above technical parameters are subject to charge without prior notice.

ST- 3DMX

ST-3DMX CONTINUOUS 3D CAT-FIXING MACHINE

- Natural and beautiful shape.

- The effect of cat whiskers is long-lasting.

- High work efficiency and reduced labor costs.

- No need to go into the oven again.

- Specifications: 6 pieces, 12 pieces.

- Continuous tunnel category specifications: 40 pieces, 80 pieces, 100 pieces.

- Process temperature 150 C

- Make value for customers, establish value for the company

STOZ

STOZ- COMPLETE OZONE TREATMENT MACHINE

The machine is completely sealed to avoid gas leakage, and the residual gas is eliminated by the purifier at the end of the program.

Control each process step through the Saiteng automatic control system to ensure reproducibility.

Ozone can also be alternately supplied to the two washing machines through a special ozone generator to increase production capacity.

Common specifications are STOZ- 400G, 500G, 600G, 1000G, 2000G, etc. For special requirements, please consult the industry or factory.

Detailed technical parameters of the model can be attained from the factory. The above technical parameters are subject to charge without prior notice.

SAITENG ELECTRICAL

ST – TS150

ST – TS150 GUIDE DEWATERING MACHINE

Excellent-quality stainless steel inner, and outer cage, beautiful and strong, with a longer service life.

Ultra hydrostatic equilibrium, first, class working environment. This machine takes up the sliding bearings (ball type) structure. Motor specially designed in the dewatering machine center. So also at a high speed when, no noise or vibrancy.

Adops advanced frequency conversion technology, adjustable speed, and energy saving. This machine from the start, speeds slowly automatically from 1 P.m. to the high-speed energy consumption will remain at the lowest level.

The advantage of the guide dewatering machine is to use automatic lifting and lowering methods to reduce working intensity.

| TECHNICAL DATA | ||||

| Model | TS 100 | TS 120 | TS 150 | |

| Rotating cage diameter | mm | 1000 | 1200 | 1500 |

| Rotating cage height | mm | 380 | 450 | 700 |

| Volume (Green – Weight) | kg | 100 | 150 | 500 |

| Power | kw | 5.5 | 7.5 | 11 |

| Rotate speed | r/min | 750 – 960 | 750 | 600 – 750 |

| Outlook size ( L ✖W✖ H) | mm | 2260 ✖2400✖ 3200 | 2200 ✖1900✖ 3000 | 2200 ✖1600✖ 2800 |

Detailed technical parameters of the model can be gained from the factory. The above technical parameters are subject to charge without prior notice.

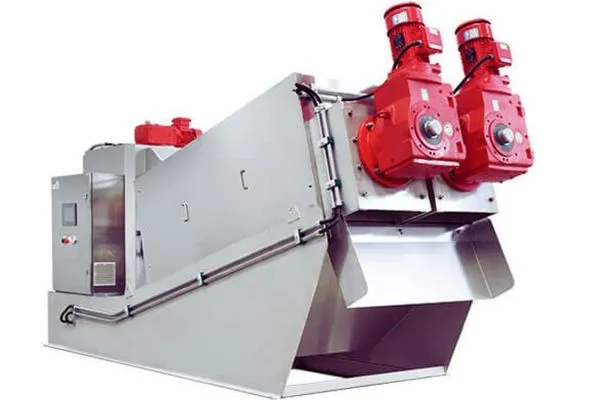

ST- R5108

ST- R5108 SEAMLESS UNDERWEAR PROFESSIONAL DYEING MACHINE

This machine is a professional dyeing machine developed by SAITENG Technology for seamless underwear dyeing.

The equipment can ask the factory for the detailed technical parameters of this model.

SAITENG ELECTRICAL

ST-Z SMART SUIT DYEING MACHINE

- A level control system has provided a high Dyeing accuracy assurance

- Dyeing circulation system/ Automatic heating system/ Automatic feeding system

- Heating system via heat exchangers

- Automatic water-introducing control(keep effluent separate from clean water during draining operation)

- Computerized control designed to keep a record of process curves

- Central control system (allows internet control Via. office PLCs)

| TECHNICAL DATA | ||||||

| Model | ST- 50 | ST- 100 | ST- 200 | ST- 250 | ST- 300 | |

| Total power KW | 1.5 | 2.2 | 2.2 | 3.0 | 4.0 | 5.5 |

| Outlook size ( L ✖W✖ H) | 2730 ✖1700✖ 1650 | 3600 ✖2100✖ 2000 | 3800 ✖2150✖ 2050 | 3580 ✖2300✖ 2200 | 4200 ✖2420✖ 2350 | 4500 ✖2420✖ 2350 |

Detailed technical parameters of the model can be received from the factory. The above technical parameters are subject to charge without prior notice.

STG- 1500

STG- 1500 LOW BATH RATIO HIGH-TEMPERATURE HIGH-PRESSURE GARMENT DYEING MACHINE

Intended for dyeing and finishing of chemical fiber, nylon, cotton, and artificial silk at high or normal temperatures (such as seamless polyester clothes and trousers, etc.)

The factory may provide detailed technical parameters for the model. The above technical parameters are subject to charge without prior notice.

ST-P

ST- P INTELLIGENT WASHING MACHINE

- A level control system has provided a high Dyeing accuracy assurance

- Dyeing circulation system

- Automatic feeding system

- Heating system via. heat exchangers

- Automatic water- introducing control

- Automatic water-draining control (Keep effluent separate from clean water during draining operation)

- Computerized control designed to keep a record of process curves

- Central control system (allows internet control Via. office PLCs)

- Technical spec parameters of the model can be obtained from the factory. The above technical parameters are subject to charge without prior notice.

- Make value for customers, build value for the company

ST- R 100

ST- R 100 PROFESSIONAL DYEING MACHINE

- High-quality stainless steel inner and outer cage, beautiful and strong, long service life;

- Automatic technology, saving energy;

- High-speed dehydration improves work efficiency;

- Ph display and automatic adjustment function.

The application of steaming

| Hosiery | Silk stockings shrinking and heat setting, improve flexibility and prevent string hooking; Texture distinctive line, improve dyeing even; Improve the hand feeling degree |

| Knitting | Increase yarn’s moisture by 1.5 – 3%Increase the breaking tenacity of cotton and flax. Strengthen the weak points of yarn, improve the quality of subby yarn Increase breaking elongation by 30%. Reduce fibrous hairiness and fly by 40%Twists setting and realization, reduce twists run back by 50%Eliminate electrostatics. |

| Spinning- improve the quality of yarn | Increase yarn’s moisture by 1.5 – 3%Increase the breaking tenacity of cotton and flax. Strengthen the weak points of yarn, improve the quality of sub by yarn Increase breaking elongation by 30%. Reduce fibrous hairiness and fly by 40%Twists setting and realization, reduce twists run back by 50%Eliminate electrostatics. |

| Dyeing | Reduced shrinkage and improved dyeing even though preshrinking. |

Detailed technical parameters of the model can be obtained from the industry. The above technical parameters are subject to charge without prior notice.

Mahedi Hasan working as an Executive (Fabric Marketing) at Pengnuo Group. Graduated with B.Sc. in Textile Engineering. Before was a Top Rated content writer at Upwork, and Level 02 Seller at Fiverr, Level 02 Publisher at Ezoic. Very passionate about content writing, SEO practice, and fashion website designing. Highly Experienced fashion writer for the last 4+ years. Have extensive 7 years of experience in the wholesale clothing business.