Testing and quality content are always part of maintaining the quality of any product. It is also part of the textile manufacturing industry. Today, I will talk about textile testing and quality control.

What is Textile Testing?

Testing is controlling, checking, or verifying the material’s nature, kind, or character, hence controlling the degree of excellence. It measures the properties and performance of textile materials.

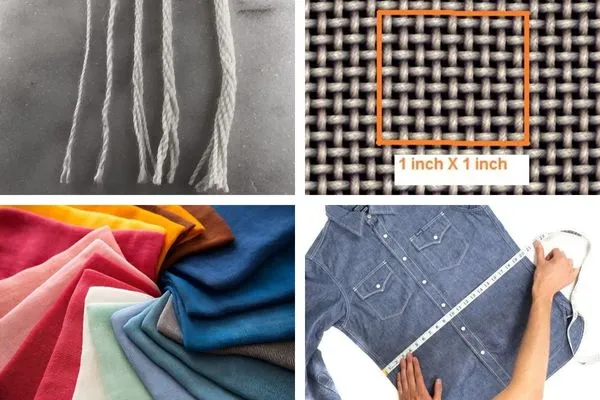

Textile testing includes physical and chemical testing of raw materials from yarn to finished products and apparel. Textile testing assists in selecting various types of fibers and their transformation into yarn, fabric, and finished products such as apparel.

It is the process of checking the yarn, fiber, fabric quality, suitability of these raw materials, and selection of materials. Textile testing is important for textile manufacturing, storage, shipment, and final uses. However, it is an expensive business but essential too.

Some reasons for textile testing include checking raw materials, monitoring production, assessing the Final product, investigating faulty material, product development, and research.

What is Testing?

Testing is the process of examining a product’s quality, quantity, and ability.

It is subordinated by 5M. They are Man, Machine, Material, Method, and Measurement.

The 5M principle is crucial for fiber and yarn testing quality control, involving Man, Machine, Method, Material, and Measurement.

1. Men:

A. Top management → Activities of Coordination, administration, Technical Supervision.

B. 80% responsibility → Top management. A man should know the demand of the textile market, recent forecasts, and the development of textile technology.

C. Quality controller → Control the testing laboratory, run, and machine maintenance.

2. Machine: Select a machine based on the technician’s skill, choosing complex or simpler for highly trained technicians or less skilled operators.

3. Materials: The selection of raw materials is a key factor in the success or failure of the product.

4. Method: Standardized methods ensure consistent product production and uniform quality in manufacturing processes.

5. Measurement: Accurate and reliable testing methods ensure the product meets specifications.

The 5M principle is essential for fiber and yarn testing to ensure high quality and meet specifications.

Objectives found in Textile Testing

The main goals of Textile Testing are as follows –

1. Research:

The results of testing in research will help the research and development department to decide which route to follow next. R&D of textiles finds the solution to different problems and challenges.

2. Section of Raw Material:

The most important details are that textile raw materials have various qualities, such as color, fineness, maturity, length, strength, TPI, EPI, PPI, CPI, WPI, shrinkage, etc. Selecting suitable raw materials is important to maximize efficiency and quality.

3. Process Control:

When processing goes out of control, the amount of waste and then several seconds increase, costs go up, and very often, tempers, too.

Spinning → Weaving/knitting → Dyeing → Finishing → Garments Making

- In the spinning process, higher-end breakage will affect the production.

- In the weaving/ knitting process, machines are stopped due to excessive yarn breakage, which will affect production.

- In the dyeing process, excessive pH (>7), temperature, time, and pressure will affect the production.

- In the finishing process, the inefficient use of finishing parameters also causes trouble in production.

So, the process must be controlled by choosing the suitable process & techniques for the material for the better process and to get optimum efficiency.

4. Product Control:

The end product of a process should fill the desired quality.

- Spinning process → Yarn, Count, Twist.

- Weaving process → Fabrics, EPI, PPI, Shrinkage.

- Dyeing process → Color matching, fastness properties.

- Finishing process → Finished fabrics, Softness.

5. Process Development:

Process development is a form of applied research. To avoid unnecessary waste of time and money & improve Quality, the machine design and setting may change. May add or discharge some process.

6. Product Development:

The textile testing of the material helps in the continual search for new product development. You should develop a sample like the desired product to produce a new item. It may change as demand for customers increases.

7. Specification test:

To manufacture garments, first, the specification of the material should be tested. Fiber → HVI, AFIS

- Specification of yarn → Count, Strength.

- Fabric → EPI, PPI, Shrinkage.

- Finished Fabric → Fastness, Softness, etc.

- Garments → Measurement of garments (length, neck, armhole, chest, sleeve, etc.)

Materials that standardized Textile Testing

A textile product’s outcome should accomplish clear and latent necessities when tested. The clear results are either given by them, or they will show the specific materials. Various organizations in the world have the main purpose of setting up textile testing standards. Many test standards are pursued to measure the standardization of materials such as yarn, fabric, etc. Test standards are used to ensure the proper materials that claim the properties of a yarn or fabric. Many standards are used in textile testing. Some are given:

- AATCC- American Association of Textile Chemists and Materials

- It is a non-profitable professional organization. It spreads the test methods among the textile industries. Dr. Louis Atwell Olney founded AATCC at first in 1921. It has developed more than 200 textile standards.

- ISO- International Organization for Standardization

- It ensures that our daily products are protected, portable, and sustainable.

- BSI- British Standards Institute

- It is one of the chief standardizations in the United Kingdom. It was founded in 1901. It generates the technical standards.

Types of Textile Testing

There are two types of textile testing.

- Routine process testing.

- Quality record testing.

1. Routine Process Testing

Routine process testing is checking characteristics in the running or after a process. It checks the quality of raw materials and verifies the quality standards. To meet their desired levels, they monitor the performance of the machines and materials. They verify the whole process with guidelines to ensure the industry standards. It checks the data verifications. It monitors the stability of the whole process. The whole process is only done by the well-trained employees.

2. Quality Record Testing

Quality record testing is one kind of testing. It is the process of recording the measurements of different objects like fabric width, weight, moisture, Strength, flexibility, temperature, etc. It can encompass several processes, such as function testing, safety testing, etc.

The Importance of Textile Testing

Textile testing is the final method in the textile industry. It ensures the quality of manufacture. It can extract the problems of manufacturing. The common sights of textile testing are:

- Testing ensures the quality of raw materials.

- It removes the harmful chemicals from the materials.

- It ensures the color of textiles.

- The abrasion resistance depends on textile testing.

- It prevents legal issues.

- It invents new product development.

- It ensures consistency in products.

- Textile testing reduces costs significantly.

Overall, textile testing plays a vital role in the textile industry.

What is Quality?

Quality means the characteristics of materials that ensure the qualification of products. It is also said to be the measurement of materials. Various tools examine quality. It works according to customer expectations.

Quality: ISO 8402-1986 standard defines quality as –

“The totality of features and characteristics of a product or service that bears its ability to satisfy stated or implied needs’’

Key aspects of quality for the customer include:

- Good design

- Good functionality

- Reliable

- Consistency

- Durable

- Good after-sales service

- •Value for money

Control: To check or verify, and hence to regulate. Without skilled and experienced technologists, ‘control’ loses its meaning.

Now know about quality control in textiles.

What is Quality Control?

Quality control: Quality control is “The operational techniques and activities used to fulfill requirements for quality.”

Quality is an attribute property, a unique feature. The nature, kind, or character of any material, hence the degree of grade of excellence, is known as quality content.

Textile quality control checks verify and regulate the degree of excellence of an attribute or property of textile material.

Quality control is the process of the quality of all products. It ensures the quality of a product. It verifies the desired level of quality in a product. It maintains the measured quantity of a product. It shows the feature of a quality. It is associated with customer needs. Quality control brings satisfaction to the communities.

What is a Quality Control System?

It is a system where the business seekers check if the product quality is sustained or not. It defines quality standards. It guides for testing and many more activities. There are two types of quality control systems. They are:

1. On-Line Quality Control:

On-line quality control occurs in the production line with sensors and data systems, such as determining periodic variation of yarn, determining yarn hairiness, etc.

2. Off-Line Quality Control:

Off-line quality control occurred in the testing lab rather than the production line, such as yarn count testing, fiber testing, fabric testing, GSM calculation, etc.

What are the Objectives of Quality Control?

The objectives of Quality Control:

1. Checking and Selection of raw material: The incoming material is checked for the required properties to ensure it meets the production conditions.

2. Monitoring Production: Production monitoring ensures quality products meet or exceed set specifications, referred to as process control.

3. Assessing the final product: The bulk production is examined before delivery to ensure it meets specifications, with steps taken to rectify faults.

4. Investigation of faulty material: Independent laboratories provide unbiased opinions on faults in disputes between suppliers and users.

5. Product development and research: Testing in research helps researchers decide which route to take next, resulting in improved or lower-cost products for customers. 6. Process development

is a form of applied research that reduces time and manpower by investigating better, cheaper, and quicker methods of material conversion.

7. Specification tests: There has been a growing demand in recent years to produce textiles to meet specifications. The advantages can be noted as –

- Prevention of deterioration in quality using inferior raw materials.

- The production of goods of known performance and

- The opportunity for a manufacturer to be informed precisely what the customer requires.

Specification tests allow users to set specifications and save manufacturers from loss by producing samples to meet customer demands.

8. Customer reputation: Testing is essential to ensure consumer satisfaction and a manufacturer’s reputation, leading to repeat orders and continued prosperity.

Quality control is governed by three “M’s.” Quality control is governed by the three M’s.

1. Men

2. Machine

3. Materials

Explain these:

1. Men: Top management → Activities of Coordination, administration, Technical Supervision.

80% responsibility → Top management.

Knowledge about the market demand, statistics, and technical development. Quality controller → Control the testing laboratory, rum, and machine maintenance.

2. Machine: The machine should be selected based on the skill level of the technician or operator.

May select more refined and complex machines for highly trained technicians or more straightforward and more easily maintained m/c for poorly skilled technicians.

3. Materials: The selection of raw materials is a key factor in the success or failure of the product.

Steps of Quality Control:

Quality control is not a single-step procedure. It is a multi-step procedure. These are as follows:

1. Sample testing.

2. Analysis of result.

3. Corrective action according to results from the analysis. To obtain quality apparel, these steps must be carried out on the textile material to be processed.

Factors affecting the quality system

- Enquire & orders.

- Services.

- Inspection & testing.

- Calibration of test equipment.

- Organizational structure.

- Quality audit.

- Training

Hi, this is Taspia Binta Yousuf, A B.Sc. in Textile Engineering student at Textile Engineering College, Noakhali. My department is fabric Engineering.