Marker making is necessary in garment production to help less fabric waste and maximize efficiency. A marker is a layout that is used to guide the cutting of fabric into garment pieces.

By using a marker, manufacturers can ensure that they are using the least amount of fabric possible to produce the desired number of garments. This can save a significant amount of money, especially for large production runs. So, marker making can help to improve the efficiency of the cutting process, as it allows cutters to cut multiple garments at a time.

In this article, you will learn about what is marker making, different types of marker making, the importance of markers, marker efficiency, objectives, application, and many more on the basis of things.

Table of Contents

What is Marker Making?

Marker is a thin paper on which we arrange the pattern paper to reduce fabric waste and increase production efficiency. Marker making is the process of applying pattern parts on a piece of fabric in the most effective way possible to reduce fabric waste.

Marker making is the method of arranging pattern pieces on a piece of paper, called a marker, in the most efficient way possible to reduce fabric waste. It gives special instructions for cutting. This can be done with both manual and computerized processes. It is a very important step in the garment manufacturing process, as it can have a most important impact on the cost of production.

Different Types of Marker Making

There are different types of marker-making in marker-making has in the apparel manufacturing industry. Apart from this, there are two main types of marker making that are manual and computerized. So let’s see their works:

1. Manual Marker Making

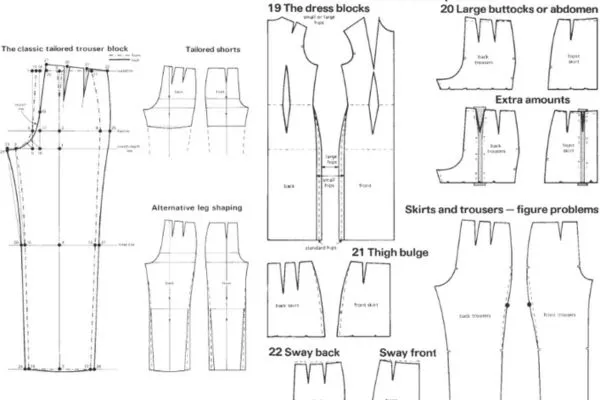

Manual marker making is the common method of marker making, and it is still used in some small-scale production facilities. In manual marker making, the marker maker uses physical patterns and a marker table to plan the layout of the marker. The marker maker must consider the fabric width, length, and grain direction when planning the marker, as well as the placement of notches and other markings. There are two main types of manual marker-making including:

- Full-size marker making: In this method, the marker maker uses full-size patterns to plan the marker. This process is more accurate, but it is also more time-consuming.

- Miniature marker making: In this method, the marker maker uses reduced-size patterns to plan the marker. This method is faster than full-size marker making, but it is less accurate.

Manual Marker Making Process

- Receive the pattern from the approved sample.

- Place the marker paper or fabric directly on the fabric ply.

- Tracing by color pen or tailor’s chalk.

- Complete the marker.

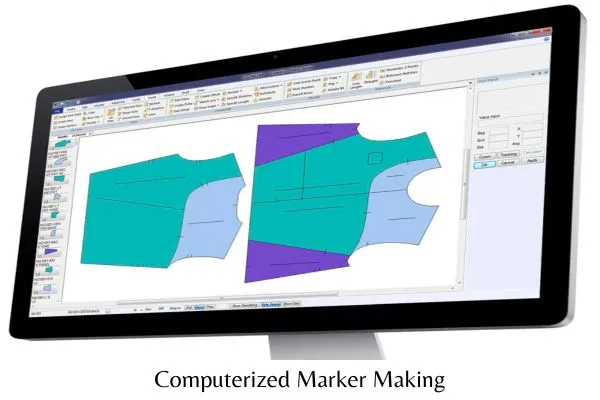

2. Computerized Marker Making

Computerized marker making is the most common method of marker making used in the apparel industry today. In computerized marker making, the marker maker uses a computer program to plan the marker. The computer program considers all of the same factors as the marker maker in manual marker making, but it can do so much faster and more accurately.

There are two main types of computerized marker-making exist including:

- Automatic marker making: In this method, the computer program automatically generates the marker based on the parameters that the marker maker inputs.

- Interactive marker making: It is a common process, where the planner makes the marker with the help of the computer. The miniature displays all the pattern pieces from the top of the screen. A horizontal line in the middle of the screen is seen which is called the width of the marker.

Computerized Marker Making Process

- Receive pattern parts from approved samples.

- Then take an image of the pattern.

- Trace the pattern design in software.

- Align all pattern parts in the marker with the software.

- Completing the marker.

Marker Efficiency

The marker planner measures his success by the proficiency of the marker plan. Less fabric will be wasted if the marker efficiency is high. The fabric price is half of the total price of the garments. So 1% marker efficiency means that profit is included with total profit. For that developing marker efficiency is more important.

Marker Efficiency Formula

Marker efficiency = (Area of pattern pieces in the marker) / (Total area of the marker) * 100%

The Factors Affecting Marker Efficiency

Factors related to marker efficiency are given below:

- Marker Planner

- Size of garments

- Marker length

- Marker width

- Pattern engineering

- Fabric characteristics

- Marker making method

Maker Making Flowchart

Receive Sketch/Design from Buyer

↓

Create block Pattern

↓

Grading

↓

Create production pattern

↓

Produce sample for approval

↓

Finalize the approved sample

↓

Create a marker manually or computerized from the approved sample pattern

↓

Cut the fabric according to the marker

↓

Sent for subsequent process

Difference Between Manual and Computerized Methods of Marker Making:

| Features | Manual Marker Making | Computerized Marker Making |

| Suitability | Small scale production | Large scale production |

| Efficiency | Comparatively less efficient | More efficient |

| Fabric wastage | High | Least |

| Time required | More time-consuming | Less time-consuming |

| Manpower required | More manpower required | Less manpower required |

| Cost | Low initial investment | High initial investment |

| Skill requirement | More skilled operators required | More skilled operator required |

| Accuracy | Less accurate | More accurate |

| Flexibility | Less flexible | More flexible |

| Grading | Grading is manual | Grading can be done automatically |

| Marker printout | Not possible | Possible |

| Changes in marker | Difficult to make | Easy to make |

Importance of Marker Making

Marker making is a very important process in the garment manufacturing process. It helps to reduce fabric consumption and wastage. Proper use of marker-making increases the efficiency of production. It helps in grading to make different components of garments according to standard body measurements. Therefore it saves time and money.

Marker making is very important in the fashion and garment manufacturing industry and requires creating proper patterns and templates for the different components of a garment before it goes into production. This is most important for the manufacturing process. This step plays an important role in ensuring the quality, fit, and cost-efficiency of the final product.

Objectives of Marker Making

- Reduce fabric wastage in cutting

- Cut bulk fabric within a short time

- Increase cutting efficiency

- Helps in grading

- Take full benefits of pattern-making

- Maintain the perfection of cutting

- Reduce wastage and time. Increase efficiency and production.

Marker making is important because fabric can be expensive, and reducing waste can save money. Marker making also helps to ensure that pattern pieces are placed accurately on the fabric. This is important for ensuring that the finished garments are the correct size and fit.

Marker making can help to improve production efficiency by allowing multiple layers of fabric to be cut at the same time. This can save time and labor costs. In addition to these main objectives, marker-making can also help.

Ensure that pattern pieces are placed accurately on the fabric, marker making can help to reduce the number of defects in the finished garments. Marker making can also help to improve the quality of the finished garments by ensuring that the fabric is cut accurately and consistently.

By reducing fabric waste and improving production efficiency, marker making can help to increase profits for garment manufacturers. Overall, marker-making is an important process in the garment manufacturing industry. It helps to ensure that fabric is used efficiently, pattern pieces are placed accurately, and production is efficient. This can lead to reduced costs, improved quality, and increased profits.

Applications of Marker Making in Various Industries

Here, we explore the diverse applications of marker-making across different industries:

i. Apparel and Fashion Industry:

Marker making plays a central role in the fashion and garment manufacturing sector. It is used for:

- Clothing Production: In the apparel industry, marker-making ensures that pattern pieces are arranged on fabric to minimize waste and maximize the number of garments produced from a fabric roll. This leads to cost savings and sustainable production.

- Variety of Garments: Marker making is used to create patterns for various types of clothing, including shirts, pants, dresses, and outerwear.

- Size Range: It enables the efficient production of different sizes and styles within a clothing line.

ii. Automotive Industry:

Marker making is vital in the manufacturing of automotive interiors, especially for upholstery and seat covers. It ensures:

- Precision Cutting: Markermaking guarantees precise cutting of fabrics, leather, and synthetic materials used in car seats, headliners, and interior panels.

- Consistency: Maintains uniformity in the appearance and quality of automotive interiors.

iii. Home Textiles:

Marker making is essential for the production of various home textiles, including:

- Bedding: For items like bedspreads, duvet covers, and pillowcases.

- Table Linens: Such as tablecloths and napkins.

- Bath Linens: Including towels and shower curtains.

iv. Industrial Textiles:

The industrial sector relies on marker making for manufacturing various products:

- Bags and Luggage: Marker making ensures efficient use of materials for making bags, backpacks, and suitcases.

- Tents and Awnings: Marker making helps in producing tents, canopies, and awnings for outdoor events and industrial use.

- Protective Covers: For equipment and machinery, marker making is used to create covers that fit perfectly.

Advantages of Marker Making

- Marker making helps to minimize fabric wastage by carefully arranging the pattern pieces on the fabric layout. This is especially important for mass production, where even a small reduction in fabric wastage can lead to significant savings.

- Marker making can help to increase production efficiency by reducing the time and effort required to cut out the garment pieces. This is because the pattern pieces are already arranged in a great way, and the marker can be used to cut multiple layers of fabric at once.

- Marker making can help to improve the accuracy of the cutting process by ensuring that the pattern pieces are always positioned correctly on the fabric. This is important for producing high-quality garments with consistent sizing.

- Marker making can be used for a wide variety of garments, there are some advantages of grading like ensuring that garments will fit people of all sizes comfortably. Also, Grading can help businesses to improve their production efficiency by reducing fabric waste and cutting time.

Disadvantages of Marker Making

- Computerized marker-making systems can be expensive to purchase and maintain.

- Computerized marker-making systems require skilled operators to use them effectively.

- Marker-making can be a time-consuming process, especially for complex garment styles.

- Marker-making systems may not be able to accommodate all types of fabric or garment styles. Such as? Napped fabrics, Piled fabrics, Stretch fabrics, such as jersey and spandex, Fabrics with large patterns or designs, and Fabrics with defects or imperfections

Final Words:

As a textile engineer, I have seen this process closely. From my point of experience, Marker making is an important process with objectives related to cost reduction, efficiency, accuracy, and consistency. It finds applications in various industries and involves quality control measures to ensure high-quality markers. Every garment and clothing manufacturing industry uses markers so that they can get benefits by using this process. So, we can say that without marker making, the industry might face fabric wastage which is prevented by using marker making.

Both manual and computerized methods have their advantages and disadvantages, and the choice between them depends on factors like scale, complexity, and available resources. Ultimately, efficient marker making is main to reducing waste, improving productivity, and maintaining high-quality standards in manufacturing.

Hello! Myself Saidul Islam. I’m Student of Textile Engineer. Currently i’m study in B.Sc in Textile Engineering from Sonargaon University (SU). Major is Apparel Manufacturing. Besides, I do On-Page SEO in Textile Details. This is very fun and enjoyable task for me, and i accomplish On-Page SEO with very sincerely.