Technical textiles are an essential part of the modern textile world. It is defined as textile materials used for their technical performance and functional properties rather than aesthetic or wearing properties.

These materials are used in various industries, from medical devices to sporting goods. This article, Textile Details, will give you an overview of what technical textile is and how it’s being used today.

First, let’s know what Technical Textile is.

Table of Contents

What is Technical Textiles?

Technical textiles are textile components and products that provide technical properties and features. The definition of technical textiles adopted by the authoritative Textile Terms and Definitions:

Textile materials and products manufactured primarily for their technical performance and functional properties rather than their aesthetic or decorative characteristics.

Textile Institute

The textile industry has a promising position in technical textiles. It is utilized to use its functional characteristics and manufacture various applications properly. Here, we will talk about technical textiles types with technical textiles examples.

Examples of technical textiles

The common technical textile products list are as follows: Reinforcement fabrics, Tents, sleeping bags, Industrial belts, Fishing nets, Conveyor belts, Carpet backings, footwear components, Insulation materials, sports nets, parachute fabrics, hot air balloons, Erosion control textiles, Oil spill cleanup materials, Spacer fabrics, Conductive textiles, Membrane structures, Tire cord fabrics, Sound-absorbing fabric, Heat-resistant fabrics, Packaging textiles, Agriculture shade nets, Medical implants, Radiation shielding textiles, Inflatable structures, Filtration membranes, Battery separators, Soil stabilization textiles, Surgical sutures, Reflective fabrics, Vibration control textiles, Electric heating textiles, Water purification textiles, Gas diffusion fabric, Reinforced hoses, Antimicrobial fabric, Electrically conductive yarns, Cooling textiles, and so on.

These are the most common technical textiles products in the technical textiles market. Most of this textile product list are fit into the 12 classifications of technical textiles.

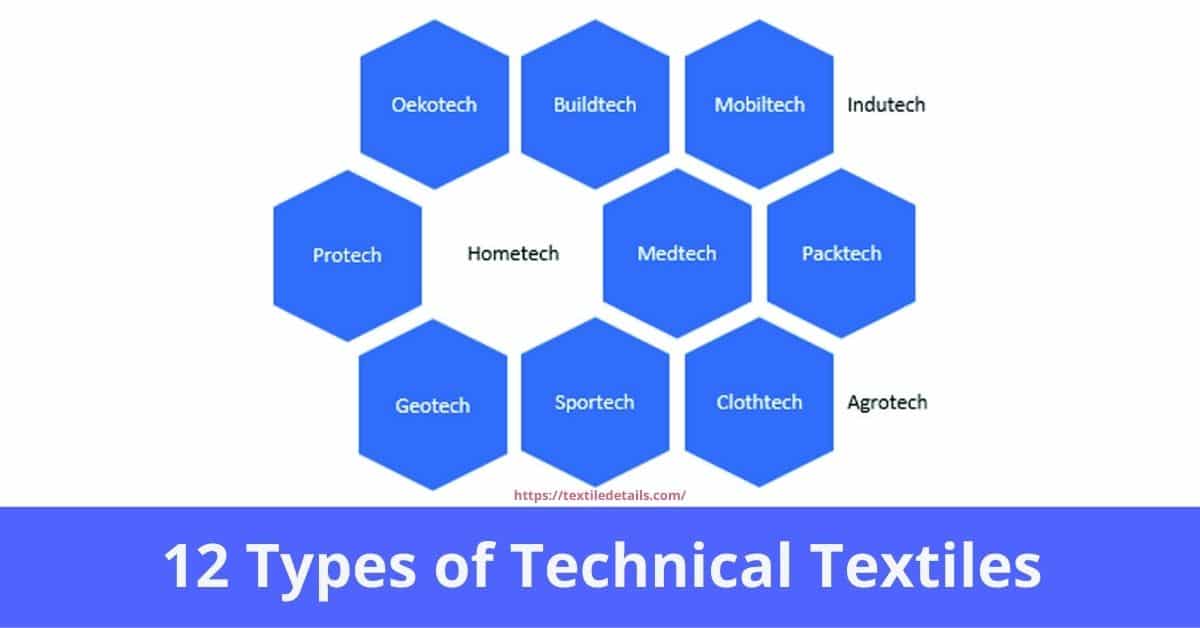

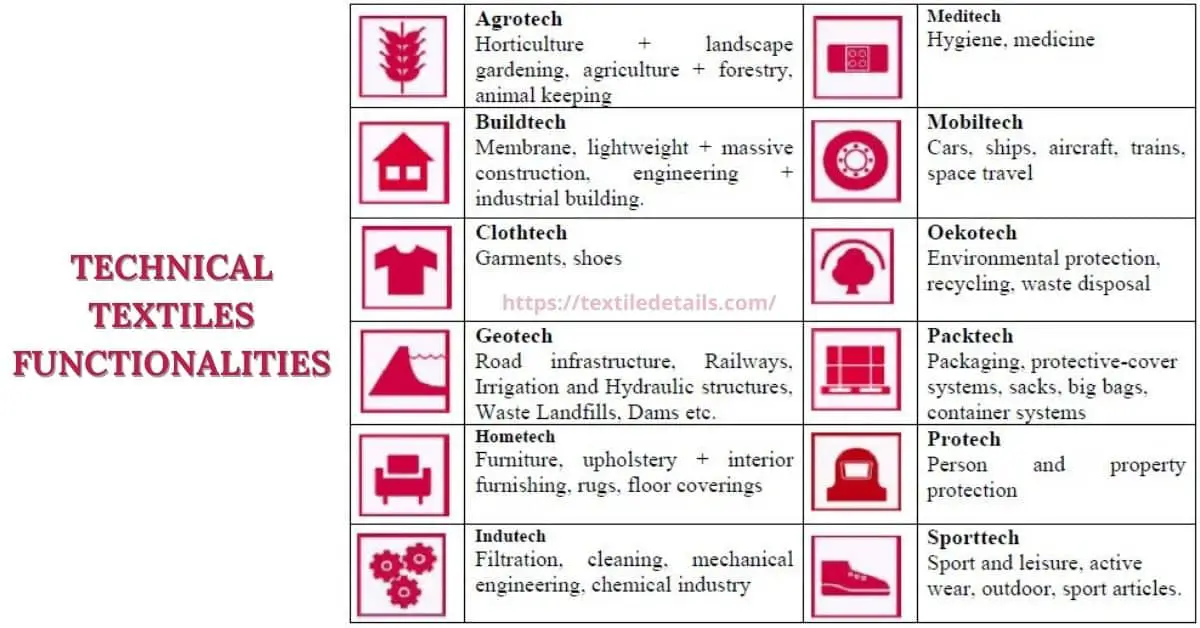

Types of Technical Textiles

There are various types of technical textile fabric manufactured in the textile industry. Technical textiles have a variety of categories depending on functionality and properties.

They provide varied performance and functionality according to the type. Different types of fabric are used for different types of work. Below is a description of the categorization and its applications:

- Agrotech or Agro-textiles: It’s used in agriculture, horticulture, aquaculture, and forestry.

- Buildtech or Construction Textiles: Mostly used in construction and Building.

- Clothtech or Clothing Textiles: Used as a material or Clothing and footwear’s technical components.

- Geotech or Geotextiles: Road, Highway, brank, etc. constructions.

- Hometech: Household and furniture and floorcoverings technical components.

- Indutech or Industrial Textiles: Industrial uses like filtration, cleaning, conveying, etc.

- Medtech or Medical textiles: Used in the Medical and hygiene industry.

- Mobiltech or Transport Textiles: Uses in Manufacturing Automobiles, railways, shipping, aerospace, etc.

- Oekotech or Ecotech: Used in oil, gas, and water transportation systems to maintain friendly protection of the environment.

- Packtech or Packaging textiles: Used in the packaging industry.

- Protech or Protective Textiles: Used in Personal and Medical Protection.

- Sporttech or Sports textiles: Used in Sportswear and Sports Equipments.

1. Agrotech (Agro-textiles)

Agrotechnical textiles, often known as agro textiles, are a form of technical textiles. It is a type of cloth used in the agricultural industry. The fabric is strong, rigid, elongated, biodegradable, UV-resistant, and toxic-free. All of these characteristics aid in the growing and harvesting of crops and other edibles. The use of biodegradable materials is becoming increasingly popular.

Features of Agrotech:

- Agrotech provides weed control and soil moisture conservation.

- It helps to maintain the growth of plants and crops in gardens.

- It keeps the soil from drying up, resulting in higher agricultural yields.

- Provide shield farmers from pesticides that are detrimental to their crops.

Application of Agrotech

Agro textiles are used in agriculture for a variety of applications. This specialized cloth has been used in a variety of agricultural applications. Crop covers, crop protectors, nets, lines, and ropes are examples of these applications. Protection of ground matting, ground screening, wind break, and tobacco cloth are also other applications of Agrotech.

2. Buildtech (Construction Textiles)

Buildtech or construction textiles help technical textiles expand their marketplace. Technical textiles that are used in construction or building purposes are called construction textiles. This textile material is used indoors and outdoors for visible and hidden uses. Using fabric coverings for roofing is an intriguing and enticing application. Textile architecture is another name for this field.

Features of Buildtech:

- Has protection against Chemical substances.

- Buildtech fabrics are of excellent quality and also durable.

- Plays a significant role in infrastructural modernization.

- Resists against the effects of chemicals, pollution, and acids in the rain.

Applications of Buildtech

Buildtech textiles are used for sun protection, waterproofing, noise insulation, and air conditioning. This fabric is also used to manufacture visual protection, thermal insulation, building safety, interior construction and other applications.

3. Clothtech (Clothing Textiles)

Clothtech is a subset of technical textiles encompassing all textile materials used in apparel and footwear. Technical textiles for clothing, particularly in the finishing process where the fabric is treated under high pressure and temperatures, support the fabric and allow for the process gradually. This is usually a polyester blend.

Features of Clothtech:

- Durable, smooth, and lightweight textile.

- Clothing textile shrinks, abrases, and is water-resistant.

- Featured with high temperature and pressure stability.

- Ensures UV radiations and corrosion resistance.

Application of Clothtech

Clothtech enhances the product with functional qualities that help it achieve particular and crucial goals. Clothtech textile is widely used in the apparel and footwear industry. Various kinds of apparel and footwear applications are manufactured from this fabric. These applications include labels, zip fasteners, interlinings, umbrellas, etc. Shoe components like fabric, sole materials, shoelaces, and fillings are the other applications of this fabric.

4. Geotech (Geo-textiles)

Geotech or Geotextile is a technical textile manufactured from man-made and natural fibers. In both the domestic and foreign sectors, geotechnical textiles are gaining acceptance. Worldwide, geo-textiles are increasingly employed to address infrastructure threats from deterioration and natural catastrophes. Geosynthetic goods will have a significant impact on the transportation sector.

Features of Geotech:

- Geo-textiles are durable, natural, and cost-effective textiles.

- Provides quick and effective protection against corrosion problems.

- Easy to use and convenient for a variety of purposes.

- Environmental efficiency, low maintenance, and commercial advantage.

Application of Geotech

These are employed in embankment reinforcement and building operations. Geotextiles are absorbent materials utilized with soils that can separate, filter, protect, or drain. Civil engineering, earth and road building, soil sealing, dam engineering, and drainage systems are among the applications.

5. Hometech (Domestic Textiles)

Hometech is another type of technical textile used in home furnishings and technical garments. Both synthetic and natural fibres are used in Hometech goods. This textiles market, which includes the upholstered furniture business and interior design, makes up a significant portion of the technical textile market. Hometech is the fourth-largest seller of all technical textiles.

Features of Hometech:

- Hometech textile is flame-retardant, anti-blotch, and anti-microbial.

- In the winter, it protects against draughts and prevents heat loss.

- Durable and has a good texture.

- Provide excellent protective properties.

Application of Hometech

Hometech textiles are used in home furnishings and interior design. A vast of products are made of this woven and nonwoven fabric. Hometech applications include Woven and non-woven knit wipes, sofa cushions, mattresses, table runners, shirt linings, platform cloth, carpet backings, etc.

6. Indutech (Industrial Textiles)

Indutech textile is a technical textile sector. Technical textiles are proving their worth in yet another industry, boosting the progressive industrial and technological front. Textiles utilized for a variety of industrial applications are referred to as Indutech. Technical textiles encompass products and solutions for mechanical and textile engineering applications.

Features of Indutech:

- Indutech textile is shrinking, abrasion, and water-resistant.

- This textile fabric features durability, and the texture is finished.

- Having high temperature and pressure stability.

- Resists the effects of chemicals, pollution, and acids in the rain.

Application of Indutech

Indutech Textiles are used for filtering, conveying, cleaning, and other industrial purposes. This textile is progressively being used in practically all significant industries worldwide. It is used in paper, carbon, ceramic, metal, plastic, woven, nonwoven, and knitted.

7. Medtech (Medical textiles)

MedTech is a term used to describe technical textiles used in the medical and rehabilitation industries. It involves creating, processing, and using safe and hygienic products. Medical textiles from the MedTech sector ensure patients receive the best care possible. MedTech products are among the most advanced technical textiles due to their high process dependability requirements.

Features of Medtech:

- Medtech Textile is resistant to bacteria, viruses, and harmful chemicals.

- It is a non-toxicity fabric, and it has a nonallergenic response.

- Excellent durability and better flexibility.

- Has biocompatibility and stability to sterilization.

Application of Medtech

Several medical products are made from Medtech textiles. Surgical gowns, mattress covers, patient clothing, Surgical hosiery, and Surgical clothing are all made of Medtech textiles. Surgical dress includes masks, Caps, Wipes, gowns, Uniforms, Beddings, Sheets, Pillow covers Etc.

8. Mobiltech (Textiles used in Transport)

Mobiltech refers to technical textiles used in the automotive and transportation industries. It’s a kind of technical fabric. Automobiles, automotive components, and aircraft and railways are among the applications. Mobiltech is concerned with isolation, safety, comfort, and aesthetics.

Features of Mobiltech:

- Comfortable, functional, and decorative fabrics.

- Add a decorative accent to surfaces.

- This textile also provides an excellent, warm, soft touch.

Application of Mobiltech

Tires, various types of tire cords, tire manufacturing, and various types of tires all use Mobiltech Textiles. Top coverings, seat covers, headliners, and carpets are all examples of automobile upholstery. Seat belts, airbags, and helmets are examples of automobile safety features.

9. Oekotech or Ecotech (Eco-friendly textiles)

The use of technical textiles in environment-friendly engineering is called Oekotech or Ecotech. Garbage management of waste, which refers to using Geotextiles materials to secure landfills against leaking toxic materials, is essential. This innovation aids in the reduction of oil extraction while reducing the negative effects on the environment.

Features of Oekotech:

- Made in Green assists in making environmentally conscious decisions.

- Has a lower carbon footprint than traditional textiles.

- Provides cost-effective and Eco-friendly sustainable textile products.

- It cuts down on water usage and hazardous runoff.

Application of Oekotech

Eco-friendly textiles are widely used in Apparel and Fashion Industries. It is also used in the textile industry and home furnishing. Secondary protection is used in the chemical and oil industries, among other things. Health Care and hygiene products, Eco Packaging, and various medical applications are also manufactured from this fabric.

10. Packtech (Packaging textiles)

Packaging for textile industries, agriculture, and other items is called packaging textiles or Packtech. Textile packaging is an excellent choice for providing scratch-free and secure handling of delicate items. These packaging are incredibly beneficial for transportation and handling in the automotive industry. One of the essential disciplines of technical textiles is packaging material. Textile products are seeing new potential as there is a demand for reusable packaging textiles.

Features of Packtech:

- Packtech textiles shield you from dangerous chemicals and gases.

- Ensures waterproofing, flame retardancy, lightness, and breathability.

- Heavyweight, densely woven fabric is used in packaging textiles.

- Suitable for industrial, consumer, agricultural, and other goods.

Application of Packtech

Textile is a packaging material used in the packaging industry. The technical textile products covered under Packtech include Polyolefin Sacks, Wrapping fabric, Leno bags, and Jute Hessian. Teabags, luggage products, Woven sacks, and food packages are all also made of Packtech textiles.

11. Protech (Protective textiles)

A protective textile is a technical textile that provides excellent protective functionalities. Sometimes, it has smart e-textiles properties. This protective functionality includes chemical protection, heat protection, cold protection, etc. Protective apparel is quite essential in the workplace. This textile has been used to defend against various natural and man-made hazards.

Features of Protech:

- It is lightweight, easy to handle, and has drape features.

- Has bacteria, Ultraviolet, and microorganism resistance.

- Highly durable, and it is wind and also Water-resistant.

- Protected from bullets, chemicals, fire, and flame.

Application of Protech

Protective textiles are used to make various protective applications like bulletproof jackets, Heat-resistant clothing, and Firefighter suits. All of these are space shuttle clothing, chemical hazard clothing, and micro-organism protection, which are Protech’s applications. All of this is possible thanks to technical fabrics made of high-performance fibers.

12. SportTech (Sports textiles)

SportTech, or Sports textiles, is a type of technical textile used in the sports sector. This fabric is suited for all climates and has a low maintenance cost. The fabric is primarily made from high polyester tire cord fibers. It’s a foam underpad set down to provide cushioning and protection against hard falls.

Features of Sporttech:

- Features of ease to adjustable, wear and handling,

- Offers a higher level of protection than other fabrics.

- Can shield you from the sun’s harmful UV radiation.

- Solid and durable and also lightweight.

Application of Sporttech

Sports textiles applications can be classified under 2 categories: Sports equipment and Sports Wear. Sports equipment like a ball, bats, bike frames, sports nets, tennis rackets, and ski and surf equipment are all made from this fabric. Sports Wear, including shoes, helmets, swimwear, t-shirts, socks, etc., is made of sports textiles.

Conclusion:

Finally, we discussed one of the most important innovations that have come out over the last decade: technical textiles. It might seem like just another material at first glance, but when you look closer, you’ll see that it has changed many aspects of our lives- from medicine hygiene products to athletic wear. So let me know which applications of technical textiles changed human life more. And which segment needs to be elaborated. We will get into more details according to your comments, till then take care.

Mahedi Hasan working as an Executive (Fabric Marketing) at Pengnuo Group. Graduated with B.Sc. in Textile Engineering. Before was a Top Rated content writer at Upwork, and Level 02 Seller at Fiverr, Level 02 Publisher at Ezoic. Very passionate about content writing, SEO practice, and fashion website designing. Highly Experienced fashion writer for the last 4+ years. Have extensive 7 years of experience in the wholesale clothing business.

We are a start up private company based in Kenya. We intend to invest in manufacturing medical textiles and IV Plant to serve the region more so, East Africa Community . After closely going through your website, we are convinced that, your abundant wealth of experience stretching back to 1970s in this industry is a boon to our maiden quest. Hence, We request for your policy on partnership and the activities you do in emerging economies in Sub-Saharan Africa.