Have you come across any weave that is distinguished by the feature of being lustrous? We believe you are certain about the Satin Weave. To know more about What is satin weave? its construction, and features, with a bit of use or application, get a quick review of this article by going through.

Table of Contents

What is a Satin weave?

Satin weave refers to the construction of a weave where there is a weft thread that floats over at least 12 warps as well as under a single warp. The next weft gets woven in different warps over same the number.

Besides, sating weave needs more shafts in the part of weaving compared to other plain weave or twill weaves. Consequently, the cost of production increases. Satin construction fabrics notably are Brocade, Crepe-satin, velvet satin, etc. Meanwhile, the Sateen is a variation of the satin weave construction with another type of yarn except for silk.

Fig: Example of Satin Weave

On the other hand, a Satin weave is also called a weave where the warp threads get interlaced with filling threads intending to produce a fabric with a smooth surface. Usually, satin fabric tends to be lustrous because of the several floats on the fabric. It is similar to sateen weaves as well. It produces a smooth, glossy surface on the fabric due to the interlacing points covered up by the threads’ floats.

What is a Satin Weave Made of?

Satin weave is well-made with different fabric types. It has a soft and smooth feel feature against the skin. Satin construction is created in a way where there is a float of some warp yarns across the weft before going under a weft thread similarly the cycle gets repeated. Since satin weave is a warp-faced fabric, there is an end per inch in more number than the picks per inch.

Satin weave creates a lustrous and smooth surface because of the use of shiny filament yarns producing the lustrous soft finish. The advantageous position is that the weaving cost of satin fabric is lower.

Meanwhile, the broken ends appear on the fac side frequently. As we have said before, there is a higher end in every inch, and the warp breakage rate of satin is more frequent. The breakage is reflected in the fabric form which does not allow any user to make any garment.

Structure of Satin Weave

Satin weave is a method of fabric weaving where the warp yarns remain stationary in a loom where the weft threads are woven over it. This weaving sort with few interlaces yields a soft surface with a smooth and lustrous effect. The two major constructions of the satin weaves are:

- The end part of the weave remains very close to each other in the Satin fabric because of the high ends per inch. Here, the ends are rubbed into each other during the shredding process in weaving. Because of this end-to-end rubbing, there is an automatic generation of hairiness in the fabric that causes pilling in the fabric too.

- The Control of the weft: Here, the weft control-wise shrinkage is easy to process. It has been always an issue during the process whether it gets shrinkage or not. If there is more warp-wise shrinkage effect after washing, the reason is to have fewer picks per inch.

The method of construction requires floating of 1 warp yarn over more than 4 weft yarns. After that, they get tied down using only 1 thread resulting in a smooth face. Another example of a satin weave is Charmeuse. It is nothing but a feathery fabric woven with a satin weave being constructed. Here, the warp threads cross over more than 3 weft threads. The fabric’s front side has a satin lustrous finish with reflective features.

Satin weave has a soft side in one part and a harsh side in another part. It is identifiable as cotton, viscose, silk, organza, and poly satin.

The Design of the Satin Weave is:

The Stripe or Check Effect on Satin Weaves by a Combination of Identical Satin Designs:

Fig: Checks

Properties

| Structure Name | Satin |

| Manufacturing Materials | Nylon, polyester, rayon, wool, and silk |

| Fabric Durability | Low |

| Fabric Breathability | Low |

| Fabric Stretchability | Good |

| Fabric Shine | Shiny and Lustrous |

| Fabric Drape Ability | Good, wrap able enough |

| Heat Retention Abilities | Premium thermal resistance |

| Prone to Wrinkle | Does not wrinkle easily. |

| Water-resistant Ability | Low |

| Washing Temperature | Maximum 30 degrees Celsius |

Advantages

Satin weave structure has the following advantages of uses. They are:

- The construction of a satin weave produces a smooth and lustrous effect on rich-looking fabrics.

- The satin weave construction is reasonably good service.

- Durability is strong in those whose fabrics are short-float compared to long-float ones.

- Satin is chosen for formal wear occasions.

- A suitable fabric for the application of coat linings.

Characteristics

Satin is well-known for being a lustrous and soft-finished fabric with a smooth surface on the outer part. Satin Weave has these characteristics to be followed. They are:

- Shiny Outer part: The different weaving technique makes satin lustrous and shiny on the right side. But on the back, it may look quite dull. It happens because of the construction of the warp and the thread of the weft.

- Sewing Difficulty: Satin has a smoothness that makes the fabric skin-friendly. It also makes the satin fabric a difficult process to sew. Before working on any bigger project, make sure you have practiced on smaller fabrics.

- Wrinkle-resistant: Satin fabric is stretchable compared to other materials. The thicker satin fabrics are not much prone to wrinkling.

- Snagging: Satin threads are prone to snag as a result, the fabric may seem unappealing.

- Aesthetic look: Satin provides a classy and sophisticated look whenever it is worn.

- Versatility: Satin weave structure is applicable to use in the making of a lot of items. From wedding dresses and ballet shoes, the versatile applicability makes the product remain popular for ages.

- Durability: It has its long fibers being woven taut. As a result, it can stay for a while without any visible cracking.

More Basic Features of Satin Weave

- Warp-faced weaves.

- There is no prominent weave structure.

- Absence of continuous twill lines.

- Thread density is possible.

- 3rd Basic weave.

- The minimum repeat is 4 x 4.

- The use of low twisted yarns.

- Long floated weave.

- Not perfect for repeated wearing.

- Warp satin A/1, and weft satin 1/4

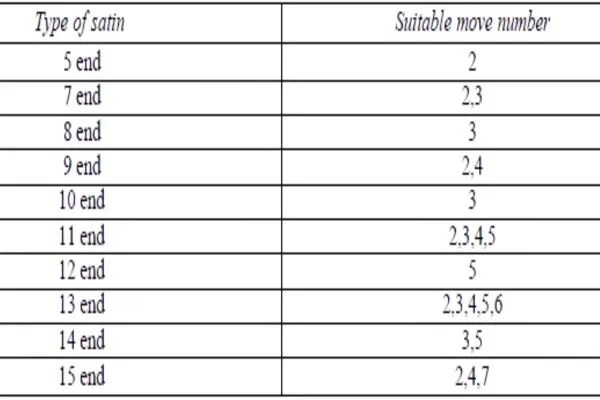

- The move numbers are essential for the construction of weaves.

Choosing move numbers for constructing the satin weaves in the following rules:

- The move number must be unequal to the weave repeat.

- There should not be 1 less than the size of the repeat.

- There should not be a repeat size factor and multiple of the factors.

| Type of Satin | Suitable move number |

| 5 end | 2 |

| 7 end | 2,3 |

| 8 end | 3 |

| 9 end | 2,4 |

| 10 end | 3 |

| 11 end | 2,3,4,5 |

| 12 end | 5 |

| 13 end | 2,3,4,5,6 |

| 14 end | 3,5 |

| 15 end | 2,4,7 |

The common style of satin fabric construction includes 4,5, and 8-shaft satins. The above-pictured weave predicts an excellent form of drapability over different compound curves. Also, it allows high strength in the direction of the surface.

FAQ’s

What is Satin Weave Used for?

Satin fabrics remain always in a warp-faced position as it is made of shiny yarns named filament. Although there is a low twist in producing the lustrous finish, the satin-woven fabrics are useful usually in the following areas:

Apparel: Both the clothing and apparel industry have a satin weave.

Dressmaking: Satin Weaves are available in couture wear and wedding dresses. Satin, being a core fabric, in the industry of fashion, is applicable for bridal wear, evening gowns, nightwear, and underwear.

Linings: The drapery linings are another way of a satin weave.

Bedsheets: Satin provides comfort; hence, it is used for a smooth and soft finish.

Fashion Accessories: Satin is the main component in making clutches, and other feminine accessories.

Footwear: Satin has an amazing place in the footwear that ballet dancers used to wear.

Upholstery: Upholstery is another use of satin weave. To make decorative furniture pieces, Europe has been at the center. Satin weave that is why, is still applicable to use in pillow coverings and furniture pieces.

How does the difference exist between Satin and Sateen?

Usually, Sain as well as Sateen both have the same weave construction. The only difference that makes is the making of different fibers. Satin has been a long filament-made synthetic fabric meanwhile Sateen is made of Short-staple fibers. Besides, you can understand the difference by watching the luxurious shiny look, although they seem the same in the outer look part.

What is the Difference between Satin and Satin Weave?

Satin Weave here means that type of fabric weave that features glossy and lustrous material on the top surface. However, the weave is not durable enough since it tends to snag.

On the other hand, Satin, as a synthetic fabric, is not breathable yet affordable enough. The only weird thing is about the manufactured bedding that tends to explore the satin sheets’ mechanism of trapping heat ability.

- What is the dissimilarity between Satin and Sateen Weave?

Satin or sateen both weaves are basic weaves using 5-12 harnesses where there is an invisible diagonal. It is common confusion to identify the difference in weave between Satin and Sateen. The key takeaways are:

| Satin Weave | Sateen Weave |

| A warp-faced fabric woven with premium quality warp yarn | A weft-faced fabric woven with premium quality weft yarn |

| Broken ends are appearing on the right side (the face side) | Sateen weave does not have any broken pick. |

Conclusion

Satin is well-made by passing more than 4 weft threads over only 1 warp or 1 weft. As a result, it leaves a few threads floating over the satin weave’s surface. Another consequence is that the satin weave does not remain firmly fastened into the weaving part. The exciting part of being satin is that the floating threads provide a shiny look. As well as they are vulnerable enough to be caught on anything that remains pulled or damaged. We believe this article is understandable in many cases on the field of satin weave’s properties, construction, and applicability procedures in brief.

Mahedi Hasan is a Textile Engineer, as well as a Top Rated content writer at Upwork, a Level 02 Seller at Fiverr, Level 02 Publisher at Ezoic. A passionate textile and fashion content writer, fashion SEO expert, and fashion web designer. Having a B.Sc. in Textile Engineering Degree from Textile Engineering College, Noakhali (TECN). The department is Apparel Engineering. Highly Experienced fashion writer for the last 3+ years. Have extensive 7 years of experience in the wholesale clothing business.