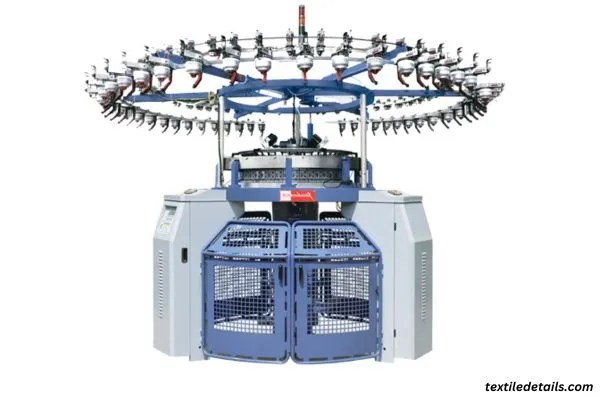

In the modern world of textile manufacturing, Single Jersey Circular Knitting Machines are a fundamental tool in the textile industry. Single Jersey Circular Knitting M/C, often referred to as S/J M/C, has witnessed significant advancements in recent years, revolutionizing the way we produce high-quality fabrics. These machines produce single-faced fabrics, characterized by a smooth surface on one side and loops on the other. In this article, we’ll show the features of a Single Jersey Circular Knitting Machine with modern single jersey machine.

Features of Single Jersey Circular Knitting Machine

- Only a cylinder is used.

- One set of needles is used.

- Max machine gauge 24/ 60 upto in modern S/J machine.

- The cylinder has cams-rising & stitch cam.

- Sinker is used / but the dial is not used.

- Vertical needle position.

- Up to 120 feeders are available.

- Machine capacity is high.

- Machine dia of 26”-30”.

- Fiber cut up to 28 is available.

Features of Modern Circular Knitting Machine

- It has a cylindrical needle bed.

- Consists of 3 major sections (yarn supply, knitting element & fabric take down).

- All three types of needles can be used.

- Sinkers and dial for dial are used.

- Needle needle-retaining spring is present.

- Yarn supply from cores situated on overhead bobbins.

- Up to 60 machine gauges are available.

- The positive feed provides 3 different speeds.

- Automatic lubrication system.

Difference between Single Jersey circular knitting machine with Modern single-jersey circular knitting

Here’s a table comparing the “Single Jersey Circular Knitting Machine” with “Modern Single Jersey Circular Knitting”:

| Feature | Single Jersey Circular Knitting Machine | Modern Single Jersey Circular Knitting |

|---|---|---|

| Knitting Technology | Traditional circular knitting technology with a single set of needles | Incorporates advanced knitting technology, often with computerized controls and multiple needle sets for enhanced efficiency and flexibility |

| Productivity | May have lower production speeds compared to modern machines | Generally offers higher production speeds, leading to increased output and efficiency |

| Needle Arrangement | Typically has a single needle set arranged in a cylinder or dial | Features advanced needle arrangements for intricate stitch patterns and varied fabric structures |

| Versatility | Limited versatility in terms of stitch patterns and fabric types | Offers greater versatility, allowing for a wide range of stitch patterns and fabric constructions |

| Control System | Manual or basic controls for stitch settings | Equipped with modern, computerized control systems for precise stitch control and pattern variations |

| Ease of Operation | May require more manual intervention and adjustments | Designed for user-friendly operation with automated features, reducing the need for constant manual adjustments |

| Yarn Handling | Handles standard yarn types efficiently | Can handle a variety of yarns, including specialty and high-performance fibers |

| Fabric Quality | Produces quality Single Jersey fabric | Capable of producing high-quality fabric with improved consistency and reduced defects |

| Maintenance | May require more frequent maintenance | Often designed for minimal maintenance, with self-diagnostic features for quick issue resolution |

| Cost | Generally more affordable compared to modern machines | Initial investment may be higher, but modern machines often provide better long-term cost-effectiveness due to increased efficiency |

| Technology Integration | Limited integration of modern technology | Integrates cutting-edge technology for enhanced performance and adaptability |

Mahedi Hasan is a Textile Engineer, as well as a Top Rated content writer at Upwork, a Level 02 Seller at Fiverr, Level 02 Publisher at Ezoic. A passionate textile and fashion content writer, fashion SEO expert, and fashion web designer. Having a B.Sc. in Textile Engineering Degree from Textile Engineering College, Noakhali (TECN). The department is Apparel Engineering. Highly Experienced fashion writer for the last 3+ years. Have extensive 7 years of experience in the wholesale clothing business.