Clothing comfort is related to Human Physiology. In this context, we will discuss the role of clothing thermal comfort.

Table of Contents

Definition of Comfort

Comfort involves thermal and non thermal components and is related to wear situation such as working, critical and non-critical conditions. When the system reaches a steady state, the physiological responses of the human body to a given combination of clothing and environmental conditions are predictable.

Fourt and Hollies(1970)

Comfort is independence from pain and from discomfort as a neutral state.

Hatch(1993)

Comfort is a pleasant state of psychological, physiological, neurophysiologic and physical harmony between a human being and the environment.

Slater (1985)

Comfort depends on subjective perceptions of visual, thermal and tactile sensations, psychological, apparel processes, body-apparel interaction and external environmental effects.

Li (2001)

Classification of Clothing Comfort

Clothing comfort can be classified into the following 3 types:

- Physiological comfort: related to the human body’s ability to maintain life.

- Psychological comfort: related to the mind’s ability to keep it functioning satisfactorily without external help.

- Physical comfort: related to the effect of the external environment on the body.

Further, the psychological and physiological states have a no. of aspects:

- Thermo physiological comfort: Development of a comfortable thermal and moisture state. It involves the transportation of heat and moisture through a fabric.

- Sensorial comfort/Tactile comfort: The elicitation of various neural sensations when a textile comes into contact with skin.

- Body movement comfort: The ability of a textile to allow freedom of movement, reduce burden, and body shaping as required.

- Aesthetic appeal: Subjective experience of clothes to the eye, hand, ear, and nose, which contributes to the wearer’s overall well-being.

Components and Influencing Factors of Clothing Comfort

- Human-clothing interactions.

- Selection of clothing.

- Physiological factors of clothing comfort.

- Psychophysics of clothing comfort.

- Thermo-regulation in the human body through the clothing system.

- Psychological aspects of aesthetic comfort.

- Neurophysiologic perceptions.

- Mechanical and thermal receptors.

Other components and influencing factors of clothing comfort are as:

- Sensory perceptions and tactile sensations of the human body.

- Fabric handle attributes, fabric parameters, and characteristics.

- Physiological requirements of the human body

Again, clothing comfort is influenced into 3 main categories:

- Factors related to the wearer(metabolism of a person, age, experiences, level of health, mental and economic position, types of activities).

- Clothing structure and chemical nature of fibers (fiber and yarn types, fabric structure, mechanical and thermal properties of fabric, clothing design, fitting).

- External conditions(moisture, ambient temperature, radiant temperature [Loose or absorb rate of temperature], wind speed).

Moisture Management

Moisture management is one of the major performance criteria in today’s clothing industry. It is defined as the ability of a garment to move moisture away from the skin and to the garment’s outer surface.

Moisture is transferred in textiles through capillary action or wicking. The idea behind this technology is to provide a faster drying rate as well as efficient moisture removal from the skin.

Factors Influencing Moisture Transport

The moisture transfer rate of clothing is influenced by the following factors:

- Complexity of pores.

- Porosity and thickness of clothing.

- Fiber-diameter.

- Shape and type (hydrophilic/hydrophobic).

- Pore size distribution.

- Gradients of temperature (Rate of temperature loss, the direction of temperature loss is called the gradient of temperature).

- Water vapor pressure/concentration.

Factors Influencing Moisture Transport

- Position of layers(hydrophilic/hydrophobic).

- Ventilation

- Atmospheric temperature and pressure.

Improving Moisture Transport

Making an inner layer of hydrophobic Fiber with the necessary capillary forces is preferable as these do not absorb moisture. The inner layer’s wicking rate can be improved by treating it with a hydrophilic finish.

Fiber surfaces with channels and grooves could also transport liquid water at a faster rate by wicking.

Fibers with unique cross-section shapes such as W-profile, grooved fibers of Cool max, and 3-T shapes have a large surface area, which increases the evaporation rate throughout the layer.

The finer capillaries spread the liquid water across a larger area, allowing it to evaporate into the atmosphere. Porosities of the layers and fiber diameter are the controlling factors of pore radius.

Fleece used in the middle layers of cold weather clothing has high porosity in order to transport water vapor by diffusion.

Transport of Perspiration

The transport of sweat depends on several significant factors, such as water vapor pressure and relative humidity of the microclimate, clothing, and outside environment, absorption-desorption of the clothing medium, heat of sorption, and the saturation/condensation of vapor into liquid or water in the dress.

The basic principles of moisture transfer between the human body and the environment. Moisture can be transferred in 3 ways:

- Moisture diffusion through clothing.

- Moisture transfer by convection (without any external help, the moisture molecule passes) and ventilation.

- Liquid moisture transport by capillaries

Moisture also can be transferred by a combination of these.

Tactile Comfort

Saville(1999) reported that tactile comfort is based on the mechanical contact of the fabric with the skin; it is softness and flexibility in movement and its lack of tingling, irritation, and cling when damp.

The tactile comfort has a relationship with fabric surface and mechanical properties.

Factors responsible for tactile comfort

- Fabric Structure and Design

- Fabric drape property

- Fabric hairiness

- Stiff fiber protruding from the fabric surface

- Actual area of material in contact with skin

- The difference in the cool feel between the fabric

- Fabric prickle

- Fabric softness

- Fabric smoothness

- Itchiness

- Fabric scratchiness

Factors for Clothing Selection

Social factors: Rural/Urban, Gender, Occupation, Occasion, Social status, etc.

1) Thermo-Physiological Comfort:

Both the heat and moisture transmission behaviors of fabric play a vital role in maintaining thermo-physiological comfort. It is the balanced condition of heat and moisture transmission.

So thermo-physiological comfort is concerned with 2 most important parameters-

1) The movement of the heat and sweat away from the body can be measured in terms of thermal insulation.

2) Water vapor resistance.

2) Thermo-Physiological Comfort

Factors that affect thermo-physiological comfort:

- The thermal insulation property of the fabric.

- Water vapor resistance of fabric.

- Total air layers trapped between the fabric.

- Water uptake by the fabric.

- Sweat-producing rate of the body.

The fabric properties can be influenced by the transfer of heat and mass

- Air permeability,

- Thermal conductivity,

- Thermal resistance,

- Wicking and absorbency,

- Moisture permeability,

- Fiber content and fabric structure,

- Specific finish of the fabric,

- Liquid vapor transport of cloth,

- Liquid vapor permeability,

- Liquid vapor resistance, etc.

Comfort Properties of Fiber

The most effective parameter in defining the comfort of the ultimate product is fiber type.

→ The important properties of fibers such as strength, durability, handle, elasticity, dyeability, luster, friction properties, moisture absorbance, heat isolation, and abrasion resistance all the physical and chemical properties of fibers and their end-products.

→ Comfort is a term that is influenced by three main properties of fibers: type, fineness, and length.

Comfort Properties of Yarn

Yarn characteristics are first of all made by the physical and chemical properties of their constituent fibers:

- Surface tension,

- fiber diameter,

- Cross-section,

- The chemical nature of the fibers, etc.

But, the spinning technique, yarn linear density, pore size in the yarn, the distribution of pore size, and blend ratio are the other parameters impacting the features of yarns such as:

- frictional properties,

- thermal insulation,

- strength,

- air permeability,

- walkability,

- bending rigidity,

- evenness,

- liquid vapor permeability,

- the characteristics of fabrics and apparel that are made of them.

Comfort Properties of Fabric Structures

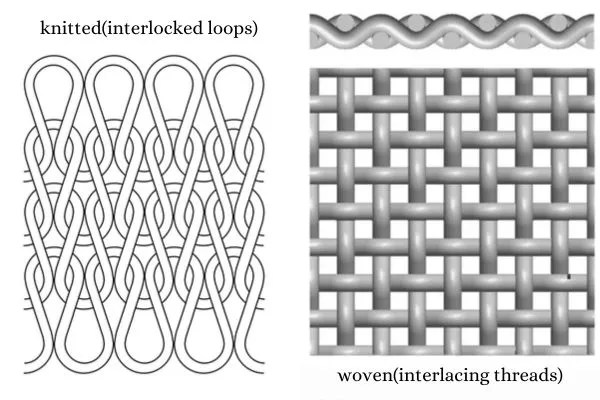

Cloth is made from fabrics that are even knitted(interlocked loops) woven(interlacing threads) or nonwoven(matted fibers).

The physical properties of the fabric create the comfort characteristics of the cloth.

The major features are fabric density, solidity, porosity, bulkiness, thickness, structure, and pattern.

Microfiber

Micro-fiber is defined as a staple fiber or filament of linear density approximately 1 dtex or less and above 0.3 dtex.

Polyester and Polyamide are the main sources although acrylic, viscose, and polypropylene are available for the production of microfiber.

The fiber’s width must be less than 1 dtex.

Fabrics made of microfiber are generally:

Lightweight, wrinkle-resistant, with a gorgeous drape across the body that holds shape and resists pilling. They are also relatively strong and durable show lower heat conductance and higher thermal insulation

What are The Parameters Influencing Heat Transfer?

Microstructure area, the heat generated by the heat source, thermal conductivity coefficient, radiant emissivity, convection coefficient, and the environmental temperature.

Principle of liquid/moisture vapor transport

- Diffusion of water vapors through layers

- Water vapor absorption, transmission, and desorption by fibers

- Water vapor migration through the fiber surface

- Transmission of water vapor by forced convection

Wicking

Wicking is the process where without any external help liquid passes through fabric. By which channel liquid passes is called a capillary. The action that occurs in the capillary action is called capillary action.

Wicking can take place either around the body to allow a greater area for evaporation through the fabric away from the skin.

Wicking is a fabric’s capacity for moving perspiration off the skin to speed its evaporation.

Test Method: In this test, a strip of fabric is suspended vertically with its lower edge in a reservoir of distilled water. The rate of rise of the leading edge of the water is then monitored.

To detect the position of the water line a dye can be added to the water or in the case of dark-colored fabrics the conductivity of the water may be used to complete an electrical circuit.

The measured height of rise in a given time is taken as a direct indication of the wick-ability of the test fabric.

Measure performance in both warp direction and weft direction

Mahedi Hasan is a Textile Engineer, as well as a Top Rated content writer at Upwork, a Level 02 Seller at Fiverr, Level 02 Publisher at Ezoic. A passionate textile and fashion content writer, fashion SEO expert, and fashion web designer. Having a B.Sc. in Textile Engineering Degree from Textile Engineering College, Noakhali (TECN). The department is Apparel Engineering. Highly Experienced fashion writer for the last 3+ years. Have extensive 7 years of experience in the wholesale clothing business.