Core Spun Yarn or Core spinning is an important concept in the field of the textile industry. To get more information about what is core spun yarn and its properties, you can go through this brief article which takes a few minutes to read.

What is Core Spun Yarn?

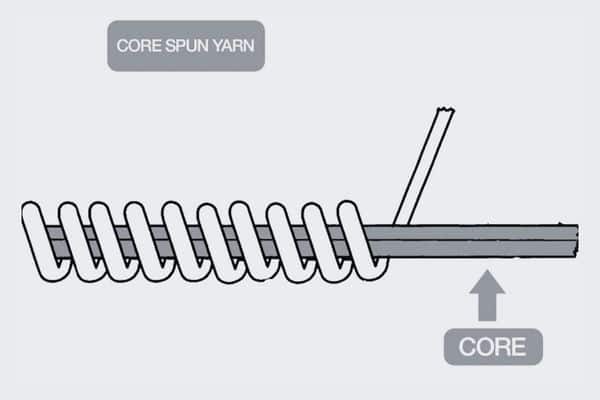

Core Spun Yarn is a dual-component structured process where fibers remain twisted around a previously existing yarn (which can be filament). Here, the already existing yarn is called the Core. In terms of core, there is used filament yarn and in terms of sheath covering, there is used staple fibers. Intending to enhance the functional properties- strength, sustainability, and stretchability, there is a significant role of the core-spun yarn.

Types of Core Spun Yarn

Core spun yarns can be found in different blends & types. They are mostly used in industrial sewing because of their immense stretchability, durability, and strength. These are:

- Cotton Core Spun

- Triblend

- Slub

- Tencel

- 100% Polyester

- Poly Cotton

- Modal

What is Core Spun Yarn Made of?

The ‘Core spun yarn’ is also renowned as ‘Polycore’ where yarn is generated around a core by twisting the existing staple fibers. The “poly” which is polyester in sense, is made to create additional strength. Besides, this yarn is also made up of Cotton, and Viscose.

The most exciting application of this yarn is the denim industry where you can find better stretchability in garment products. In most cases, this yarn is popularly known as a “cotton core” or “p-core” as well.

Manufacturing Process:

Step 1: It is just about wrapping any cotton/polyester material around an existing filament during the core-spinning process. After that, these yarns are plied into a thread of sewing. If the filament is polyester-made, then the core approximately makes up more than 50% of the thread-like construction.

Step 2: Dual-core spun yarn is changeable into a ring spinning method to facilitate fiber feeding in a continuous process.

Step 3: Each of the filaments is pushed in a way where the aid provides a suitable feed curler.

Step 4: They are used to enter a nip factor through a curler. When cotton fibers pass through, they cover up those additional filaments.

Among these steps, the important approach is to integrate and combine several filaments in a ring-like shape.

Spinning Methods

Among several spinning methods in the textile industry, the following are suitable for a core-spun yarn manufacturer. These are:

- Vortex Spinning

- Ring Spinning

- Electrostatic Spinning

- Self-Twist Spinning

How a Poly and Cotton Wrapper contributes to Core Spun Yarn?

| Poly Wrapper | Cotton Wrapper |

| Ideal color fastness | Heat resistance capability is high while being covered by Cotton. |

| Better Chemical & Abrasion Resistance | There is a feature of appearance which is the “Wash-Down” stitch. |

| “Union” or One-Step Dyeing Process which is superior in nature | Strong threads. |

Properties of Core Spun Yarn

Physical Properties

| Key Points | Properties |

| Manufacturing Materials | Cotton, Viscose, Poly |

| Durability | High |

| Breathability | High |

| Stretchability | Better |

| Moisture-absorbing Capabilities | Good |

| Ply Security | Better |

| Abrasion Resistance Ability | Superior |

| Applications | Denim Industry |

Mechanical Properties

| Parameters | Units |

| Yarn Linear Density | 19.7 (30) Tex (Ne) |

| Elastane Linear Density | 44 dtex |

| Twist Per meter | 885 No. |

| Tenacity | 15.49 xN tex-1 |

| Elongation | 8.15% |

| CVm | 11.71% |

| Imperfection Index | 43.3 |

Characteristics of Core Spun Yarn

Core Spun Yarn has wide-ranging features that help itself get flourished in the Garment Industry. Whatever the reason you have, to look for Core spun yarn, keep remember the following features in mind:

- Softness.

- Shape recovery.

- Easy-to Care.

- Better Flexibility.

- Higher Tenacity.

- Great consistency in terms of size and other physical features.

- Expensive Cost.

- Fire-resistant fibers, etc.

Advantages of Core Spun Yarns

There are a few advantages of Core Spun Yarns including producing new products, and easy-washing methods without any hassle. The advantages are given in the following part:

- Introducing New Products: The yarns with the ring spinning method produce better products. It discloses the path of creating new products in the development of the textile industry.

- High Performance: Because of their high-performance ability, such yarns possess exceptional durability and strength.

- Easy-Washing: Easy to wash and wearable.

Applications of Core Spun Yarn

The yarn helps to curtail the open seams as well as the seam failure. It also helps to cut down broken stitches. Besides, it offers the utilization of a small thread diameter to shorten the needle cutting segment. Because of the high cost, the cost of production may get increase. The applications are diversified and used in mattresses, quilts, and leather products, for an instance, ladies’ handbags, shoes, etc. Core spun yarn is also used in rice bags for its high durability and firmness. Besides, they are fire-resistant. Because of their versatile usability, these yarns are also used in making clothes, institutional uniforms, decorative crafts, and sheets.

Final Words

The woven corduroy fabric of core spun yarn has created the path of producing new stretchable denim products. Because of this yarn, denim apparel is so popular in every region of the world. Be it a polyester or cotton wrapper, this yarn provides an extensive package of applications to use in leather products. The advantages of core-spun yarn exceed the expensive cost factor which offers us a look forward to using it.

Hmm is anyone else encountering problems with the pictures on this blog loading? I’m trying to find out if its a problem on my end or if it’s the blog. Any feed-back would be greatly appreciated.