Yarn is a fibrous material made by twisting many fibers to produce fabric. It is a fundamental unit of fabric. The strength, flexibility, and performance of a textile fabric depend on the yarn/fiber as well as the construction of the fabric. Knitting and weaving factories and all other textile industries depend on yarn to produce textiles. This article will discuss what is yarn the production of yarn. Also, the classification of yarn, characteristics of yarn, and application of yarn will be addressed here-

Table of Contents

What is yarn in textile?

Define yarn count: Yarn can be defined as a long, continuous, and flexible strand of fibers. It could be natural or synthetic made. Yarn is twisted or spun to form a cohesive, durable, thread-like structure. Yarn is an essential component of the textile industry and is used to create various fabrics, clothing, and textiles.

However, beyond its technical definition, yarn symbolizes the interwoven threads of human creativity, innovation, and tradition. It comes together to create something beautiful, functional, and enduring.

Classification of Yarn

The yarn can be classified into 3 main categories. They are as follows:

1. Spun Yarn:

Spun yarn is made by twisting or spinning fibers to create a continuous strand of yarn. There are several different types of spun yarn, including:

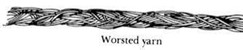

a. Worsted yarn:

Worsted yarn type of yarn is made from long-staple fibers combed to remove any shorter fibers. Worsted yarns are typically smooth and strong, making them ideal for knitting or weaving garments that require a lot of durabilities.

b. Semi-worsted yarn:

Semi Worsted type of yarn combines some of the qualities of both worsted and woolen yarns. Semi-worsted yarns are typically made from longer fibers than woolen yarns but not as long as worsted yarns. This gives them a balanced texture that is both smooth and soft.

c. Woolen yarn:

Woolen yarn is made from shorter fibers that have not been combed. Woolen yarns are typically softer and fuzzier than worsted yarns, making them ideal for knitting or weaving garments that require warmth and insulation.

d. Carded yarn:

Carded yarn is made by carding the fibers (i.e., separating and aligning them) before spinning. Carded yarns are typically less smooth and more uneven than combed yarns, but they can also have a lot of texture and character.

e. Combed yarn:

Combed yarn is made by combing the fibers before spinning, which removes any short or uneven fibers. Combed yarns are typically smoother and more even than carded yarns, making them ideal for creating very fine or delicate fabrics.

f. Chenille yarn:

Chenille yarn is made by wrapping a core yarn with short lengths of fiber, which are then twisted together to create a fuzzy texture. Chenille yarns are typically used for creating soft, plush fabrics. Example: Chenille Fabric.

g. Boucle yarn:

Boucle yarn is made by looping one or more strands of yarn to create a bumpy, textured surface. Boucle yarns are typically used for creating textured fabrics with much visual interest.

2. Filament Yarn:

Filament yarns are made by extruding long, continuous fibers from a spinneret and then twisting them together to create a single strand of yarn. There are several different types of filament yarns, including:

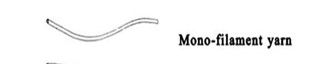

a. Monofilament yarn: Monofilament yarn is made from a single, continuous filament. Monofilament yarns are typically very smooth and strong, and they are often used in fishing lines, tennis racket strings, and other applications where strength and durability are important.

b. Multifilament yarn: Multifilament yarn is made from several filaments twisted together to create a single strand of yarn. Multifilament yarns are typically softer and more flexible than monofilament yarns, making them ideal for use in textiles and other applications with a softer feel.

▪️ High-tenacity yarn: High-tenacity yarn is made from filaments treated with special chemical coatings to make them stronger and more durable. High-tenacity yarns, such as industrial fabrics, ropes, and webbing, are often used in applications with critical strength and abrasion resistance.

▪️ Microfiber yarn: Microfiber yarn is made from very fine filaments (less than one denier) tightly woven to create a soft, lightweight yarn. Microfiber yarns are often used in clothing and bedding because of their soft, luxurious feel.

3. Textured Yarn:

Textured yarns are produced using special techniques that modify the structure of the yarn, creating unique and interesting textures. Textured yarns can add interest and dimension to knitted or woven fabrics, making them popular for various projects. Some common types of textured yarns include:.

a. Slub yarn: Slub yarn is made by spinning fibers with varying thicknesses, creating thick and thin areas in the yarn.

b. Spiral or corkscrew yarn: Spiral yarn is made by twisting two or more strands at different rates, creating a spiral or corkscrew effect.

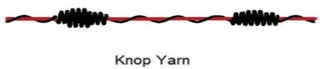

c. Knop yarn: Knop yarn is made by adding small bumps or “knops” to the yarn at regular intervals.

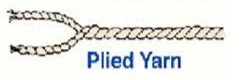

d. Plied yarn: Plied yarn is made by twisting two or more strands together, creating a smoother and more durable yarn.

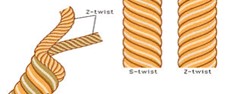

e. S-twist and Z-twist yarn: S-twist and Z-twist terms refer to the direction of the twist in the yarn. S-twist yarns are twisted in a counterclockwise direction, while Z-twist yarns are twisted in a clockwise direction.

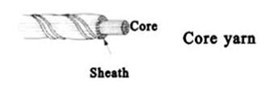

f. Core-spun yarn: Core-spun yarn is made by wrapping fibers around a central core yarn, creating a strong and durable yarn with a unique texture.

g. Brushed or fluffy yarn: Brushed yarn is made by brushing the surface of the yarn to create a soft and fluffy texture.

Characteristics of Yarn

Fabric handles, sensorial convenience, aesthetic, and performance properties are all influenced by fabric surface properties. Fabric surface properties are affected by yarn properties, one of the most important parameters. The characteristics of yarns used to manufacture textile fabrics and garments significantly impact their efficiency.

What yarn characteristics are needed for sewing threads? These areas:

- Regularity: Only very regular yarns can be used to sew smooth fabrics. Spin yarns accomplish this by doubling, drafting several times, and combing the short fibers.

- Strength: Yarn strength is determined by the fibers’ consistency, the yarn’s regularity, and the loop. Folding increases the strength of the material.

- Hardness: Twist density influences the hardness of a thread and, as a result, the handle and shape of textiles.

- Extensibility: When it comes to yarn processing and use, elasticity and extensibility are crucial. The fiber type and spinning mechanism primarily determine them.

What is Count in Textile?

Define yarn count: Yarn count is a numerical measurement that refers to the fineness or thickness of a yarn. It is an essential characteristic of a yarn that affects the quality of the final textile product. Yarn count determines the fabric’s quality, appearance, and durability.

Types of count in textile

A finer yarn produces a softer and more luxurious fabric, while a coarser one produces a more durable and hard-wearing one. The yarn count also influences the cost of production, with finer yarns generally being more expensive than coarser ones.

There are mainly two types of yarn count. Those are –

1. Direct yarn count:

Direct yarn count refers to determining the thickness or fineness of a yarn by directly measuring its linear density. It is expressed as the weight of yarn in grams per unit length, usually in meters or yards.

W X l

Direct count: N =————–

W X L

Where,

N = The yarn number or, count.

W = The weight of the sample.

W = The unit weight of the sample.

L = The length of the sample.

L = The unit length of the sample.

The different types of direct yarn count methods used in the textile industry include:

- Metric count (also known as the kilometer count or km count)

- English count (also known as the cotton count or Ne count)

- Denier count (used mainly for measuring the thickness of synthetic fibers)

- Tex count (used mainly in Europe for measuring the thickness of yarns)

- Worsted count (used for measuring worsted yarns, which are made from long-staple fibers)

- Woolen count (used for measuring woolen yarns, which are made from shorter fibers)

- Linen count (used for measuring linen yarns)

- Jute count (used for measuring jute yarns)

- Flax count (used for measuring flax yarns)

- Hemp count (used for measuring hemp yarns)

2. Indirect yarn count:

Indirect yarn count is a method of determining the thickness or fineness of yarn by counting the number of yarns in a fixed length and weight. It is also known as the indirect yarn numbering system. Indirect yarn count is commonly used for spun yarns, especially cotton, wool, and other natural fibers.

W x L

Indirect count: N=————

W X l

Where W = The weight of the sample.

W = The unit weight of the system.

L = The length of the sample.

L = The unit length of the sample.

Some common types of indirect yarn count methods include:

- Cotton Count ( Used for estimating the yarn count of cotton fibers)

- Worsted Count ( Used for estimating the yarn count of worsted wool fibers)

- Woollen Count ( Used for estimating the yarn count of woolen wool fibers)

- Hank or Skein Count ( Used for estimating the yarn count of hand-spun yarns)

Properties of Yarn

1. Physical properties of Yarn :

The physical properties of yarn describe its characteristics related to size, shape, weight, and appearance. These properties can affect how yarn is used and performed in different applications. Some of the most important physical properties of yarn include the following:

i. Fibre content: The type of fiber used to make yarn can affect its physical properties, including color, texture, and durability.

ii. Yarn weight: Yarn weight is determined by its thickness and is typically classified into different categories, such as lace, sport, worsted, and bulky.

iii. Yarn twist: The amount of twist in a yarn affects its appearance, texture, and strength. High-twist yarns are typically more durable and less likely to pill but may be stiffer and have less drapery.

iv. Yarn diameter: The diameter of a yarn strand affects its thickness and the density of fabric or textile made from it.

v. Yarn texture: The texture of a yarn refers to its surface characteristics, such as smoothness or fuzziness.

v. Yarn color: The color of yarn can affect the appearance of a finished project and how it interacts with other colors in the same project.

vi. Yarn elasticity: Elasticity refers to a yarn’s ability to stretch and return to its original shape. This can affect the fit and comfort of garments made from yarn.

vii. Yarn twist direction: A yarn’s twist, either S-twist or Z-twist, can affect the appearance and behavior of a finished project.

2. Chemical Properties of Yarn:

The chemical properties of yarn are an important consideration for manufacturers and users, as they can affect the behavior and performance of yarn in different applications. Some of the most important chemical properties of yarn include:

i. Chemical composition: The chemical composition of yarn, including the type of fiber used, can affect its behavior and performance in different environments.

ii. pH: The pH of a yarn can affect its color and durability and its ability to resist damage from chemicals or moisture.

iii. Dye ability: The ability of a yarn to absorb and retain dye can be affected by its chemical composition and structure.

iv. Flammability: The flammability of yarn can be affected by its chemical composition and structure and by the presence of additives such as flame retardants.

v. Resistance to UV radiation: The ability of a yarn to resist damage from UV radiation can be affected by its chemical composition and structure, as well as by any treatments or coatings applied to the yarn.

vi. Chemical reactions: Chemical reactions between yarn and its environment can affect its behavior and performance over time.

Mechanical Properties of Yarn:

The mechanical properties of yarn are important factors that affect its behavior and performance in different applications. Some of the most important mechanical properties of yarn include:

i. Tensile strength: A yarn’s tensile strength refers to the force it can withstand before breaking. This property is important in applications where the yarn is subjected to tension, such as in manufacturing ropes or textiles.

ii. Elongation: Elongation is the stretch a yarn can undergo before it breaks. Yarns with higher elongation can be more flexible and absorb shocks or vibrations.

iii. Modulus: The modulus of yarn measures its stiffness or resistance to deformation under a given load. A high modulus can make a yarn more resistant to stretching or bending and less flexible.

iv. Abrasion resistance: Abrasion resistance is the ability of a yarn to withstand wear and tear caused by friction. This property is important in applications where the yarn is in contact with other materials or surfaces.

v. Pilling resistance: Pilling is the formation of small balls of fiber on the surface of a fabric or textile. Yarns with higher pilling resistance are less likely to form pills and maintain a smoother appearance.

vi. Moisture absorption: The ability of a yarn to absorb moisture can affect its behavior and performance in different environments. Some yarns, such as wool, have high moisture absorption, making them more comfortable to wear in hot or humid conditions.

These are just a few examples of physical, chemical, and mechanical properties that can affect the behavior and performance of yarn in different applications. Manufacturers and users of yarn often consider a combination of these properties when selecting the most appropriate yarn for a particular application

Application of Yarn

Yarn is used in various applications such as clothing and apparel, Home textiles, Technical textiles etc. Here is a brief overview of the application of yarn :

A. Clothing and apparel :

Yarn can be used in a variety of ways in clothing and apparel. Different types of yarn are available in the market, ranging from natural fibers like cotton and wool to synthetic fibers like nylon and polyester. The application of yarn in clothing and apparel is given below :

- Knitted garments: In the knitting process, the yarn is fed through a series of loops, or stitches, to create the fabric. Applying yarn in knitted garments is essential to achieve the desired characteristics of the final product.

The yarn type, thickness, and color play a role in the knitted fabric’s appearance, texture, and performance. The thickness of the yarn used in knitted garments is also an important consideration. Thicker yarns are typically used for heavier and warmer garments, while thinner yarns are used for lighter and more delicate fabrics.

The yarn count, which measures the thickness of the yarn, is an important factor in determining the overall appearance and texture of the knitted fabric.

- Woven garments: In woven garments, the yarn is woven together to create the fabric through interlacing. This involves crossing the yarns over and under each other in a specific pattern to create a stable and cohesive fabric.

Applying yarn in woven garments is crucial to the finished product’s quality, appearance, and functionality. Different types of yarn are used depending on the desired characteristics of the fabric, such as strength, softness, elasticity, or texture. The thickness of the yarn, known as the yarn count, also affects the fabric’s weight, drape, and breathability.

B. Home textile :

Yarn is a crucial component in the production of home textiles. Yarn is used in various home textile products, from curtains and bed linens to rugs and towels. Here are some common applications of yarn in home textiles:

- Bedding: Yarn is versatile in various applications, including bedding. In bedding, yarn is typically used to create the fabric that covers the mattress, pillows, and blankets. Yarn can be made from various materials, including cotton, silk, wool, and synthetic fibers.

The type of yarn used in bedding can impact the texture, durability, and overall quality of the bedding. Yarn can be woven or knit into various patterns and textures, creating a unique and comfortable sleeping experience. Additionally, using high-quality yarn in bedding can help regulate body temperature and provide a comfortable sleeping environment.

- Towels: Yarn is an essential component in the production of towels, as it determines the quality and durability of the final product. Towels made from high-quality yarn are softer, more absorbent, and long-lasting. The yarn used in towels is typically made from cotton, which is highly absorbent and soft.

However, other materials such as bamboo, linen, and polyester can also be used. In the towel manufacturing process, the yarn is spun into threads, which are then woven into a fabric. The yarn quality in this process affects the towel’s thickness, softness, and absorbency.

- Curtains: Yarn is commonly used in curtains for weaving and creating various types of fabrics. Yarns of different materials, such as cotton, silk, wool, and polyester, are used to make curtains. They are woven together to create various patterns and textures that add aesthetic appeal to the curtains. The thickness and weight of the yarn used can also affect the opacity of the curtains, providing varying levels of privacy and light filtration.

Furthermore, yarns can be dyed to create different colors and patterns, allowing for a wide range of design options in curtain production. Applying yarn in curtains provides a versatile and cost-effective solution for decorating windows and enhancing the overall look of a room.

C. Technical Textile

Yarn is vital in producing technical textiles, which are fabrics designed for specific functions such as resistance to fire, water, or abrasion. Technical textiles are widely used in the healthcare, construction, and automotive manufacturing industries. Some common use of yarn in technical textiles are given below:

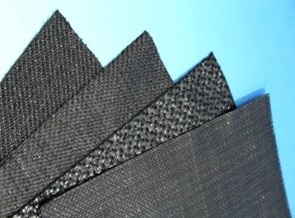

- Geotextile: Yarn is woven or knitted into a variety of geotextile fabrics, which can be used for a range of applications, including erosion control, soil stabilization, drainage systems, and road construction. These fabrics strengthen and stabilize soil structures, prevent erosion and sedimentation, and facilitate water drainage and filtration.

Geotextile fabrics made from yarn are also used in environmental protection applications, such as landfill liners, where they can prevent leachate contamination and protect groundwater resources. Additionally, they are used in construction projects to provide a stable foundation for buildings, roads, and other structures.

- Medical Textiles: Yarn has found applications in various fields, including medical textiles. One of the main applications of yarn in medical textiles is to produce surgical sutures. Sutures are used to close wounds or incisions during surgical procedures.

Yarns made from silk, polyester, nylon, and polypropylene are commonly used to make sutures due to their strength, biocompatibility, and sterilization ability. Yarns also produce medical dressings such as bandages, gauze, and compresses.

The yarns used in medical dressings are chosen based on their ability to absorb and retain fluids and softness and conform to the body’s contours. Cotton, rayon, and other synthetic fibers are commonly used. Yarns made from specialized materials such as antimicrobial fibers are also used to produce medical textiles that can help prevent the spread of infections.

- Automotive Textiles: Yarns are essential in producing various textiles used in the automotive industry. Automotive textiles have many applications, including seat covers, carpets, floor mats, headliners, and trunk liners.

Yarns used in automotive textiles must have specific characteristics such as durability, strength, and resistance to wear and tear. One type of yarn that is commonly used in the production of automotive textiles is polyester yarn. This type of yarn is known for its strength and abrasion resistance, making it ideal for seat covers and carpets.

Other types of yarn used in the automotive industry include nylon, acrylic, and polypropylene. In addition to the type of yarn used, the method of yarn construction also plays an important role in producing automotive textiles. For example, twisted yarns are commonly used to produce seat covers and carpets. In contrast, high-performance yarns such as aramid and carbon fibers produce specialized automotive textiles such as airbags.

Conclusion

Yarn is an essential component of the textile industry, serving as the foundation for creating a wide range of textile products. The relationship between yarn and textiles is crucial in the textile industry. From natural fibers like cotton and wool to synthetic fibers like polyester and nylon, the type of yarn used is crucial to the quality and functionality of the final textile product. The quality of the yarn used directly affects the quality of the final textile.

Yarn’s future in the textile industry is promising, focusing on sustainability, innovation, and automation. The development of eco-friendly yarns and technological advancements will continue to drive the industry’s growth and meet the evolving needs of consumers. The continued evolution of yarn technology and production methods will play a critical role in shaping the future of the textile industry.

Author of this article

Shamima Akter Riya

B.Sc. in Textile Engineering

Dept. Of Yarn Engineering

Textile Engineering College, Noakhali

Email: shairiya11001@gmail.com

Shamima Akter Riya is a 2nd Year Student at Textile Engineering College, Noakhali. She is doing B.Sc. in Textile Engineering from the Department Of Yarn Engineering.